Datasheet

13© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard C1049_GOLDMAX_C0G • 1/11/2019

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Radial Leaded Multilayer Ceramic Capacitors

Goldmax, 300, Conformally Coated, C0G Dielectric, 25 – 200 VDC (Commercial Grade)

Soldering Process

Recommended Soldering Methods:

• Solder Wave

• Hand Soldering (Manual)

Recommended Soldering Prole:

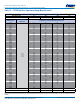

• Optimum Wave Solder Prole

0

25

50

75

100

125

150

175

200

225

250

1 2 3

Time (Minutes)

Degrees – Cº

4 5 6

Flux Zone Preheat Zone

Entrance to Solder Wave Exit from Solder Wave

Hot Air Debridging

Exit from

Solder

Machine

(Time in Wave – 2 to 4 Seconds)

Solder Wave Peak

Temperature 260ºC

Entrance

to Solder

Machine

80ºC

to 120ºC

Bottom Side

Temperature

Range

Top Side

Nominal

150ºC

Maximum

Free

Air

Cool

Entrance to

In-Line Cleaner

Exit from

In-Line Cleaner

(time in cleaner

may be less)

Immersion in

Cleaning

Vapor

Mounting

All encased capacitors will pass the Resistance to Soldering Heat of MIL-STD-202, Method 210, Condition C. This test

simulates wave solder topside board mount product. This demonstration of resistance to solder heat is in accordance with

what is believed to be the industry standard. More severe treatment must be considered reective of an improper soldering

process.

The above gure is a recommended solder wave prole for both axial and radial leaded ceramic capacitors.

• Hand Soldering (Manual)

Manual Solder Profile with Pre-heating

Gradual Preheat

60 – 120 Seconds

Recommend 2.5°C/second

Soldering

Maximum 3 seconds

Delta T < = 120ºC

Gradual Cooling