Installation Guide

DESCRIPTION

n 100% acrylic-based textured finish

n Dirt Pick-up Resistance (DPR): The

surface of the finish hardens and

does not soften again under heat.

The non-tacky surface provides high

resistance to accumulation of dirt,

mold, and pollutants.

n Integrally colored with high-quality

pigments

n Exceeds ASTM and ICC Acceptance

Criteria

USES:

Exterior or interior finish coat over:

n El Rey Insul-Flex EIFS

n Properly prepared masonry, stucco,

and concrete surfaces

n Interior application over drywall,

plaster, or properly prepared

masonry or concrete

COMPOSITION:

n Binder base: 100% acrylic polymer

with surface-hardening property.

n

Aggregate: Pure crushed marble,

rust-free.

n Water-based: VOC–compliant

n Pigment base: Titanium dioxide.

n

Color: Parex USA standard colors

or tinted to desired custom

color. Meets SCAQMD Rule 1113

when using Parex USA Non-VOC

Colorants.

DRYING TIME:

24-48 hours under normal conditions.

High humidity and low temperatures

extend drying time.

CLEAN-UP:

Water-soluble prior to drying. Clean

tools and containers with water prior

to drying.

*Tested with El Rey Basecoat

Test Method Criteria Results

Abrasion Resistance* ASTM D968

No cracking or loss of film integrity

at 528 quarts (500 L) of sand

Pass @ 1000 Liters

Accelerated Weathering

ASTM G153

(Formerly

ASTM G23)

No deleterious effects at 2000 hours

when viewed under 5x magnification

Pass

Flexibility (Mandrel Bend)

ASTM D522,

Method B

No Requirement 1” Diameter at -4ºF

Freeze/Thaw Resistance *

ASTM E2485

No deleterious effects at 10 cycles

when viewed under 5x magnification

Pass @ 60 Cycles

Mildew Resistance* ASTM D3273

No growth supported during 28 day

exposure period

Pass @ 35 Days

Mildew Resistance* MIL 810 B508 No Growth 28 Days

Moisture Resistance* ASTM D2247

No deleterious effects at 14 day exposure

Pass @ 28 Days

Salt Fog Resistance* ASTM B117 No deleterious effects at 300 hours Pass @ 900 Hours

Scrub Resistance ASTM D2486 No Requirement Pass @ 10,000 Cycles

Surface Burning

Characteristics

ASTM E84

Individual components shall each

have a flame spread <25, and smoke

developed < 450

Flame Spread: 0 to 15

Smoke Developed: 0 to 15

Water Vapor Transmission

ASTM E96

Procedure B

Vapor Permeable Permeable

VOC

EPA Reference

Test Method 24

US EPA, South Coast AQMD and

Greenseal Standard

8 g/L

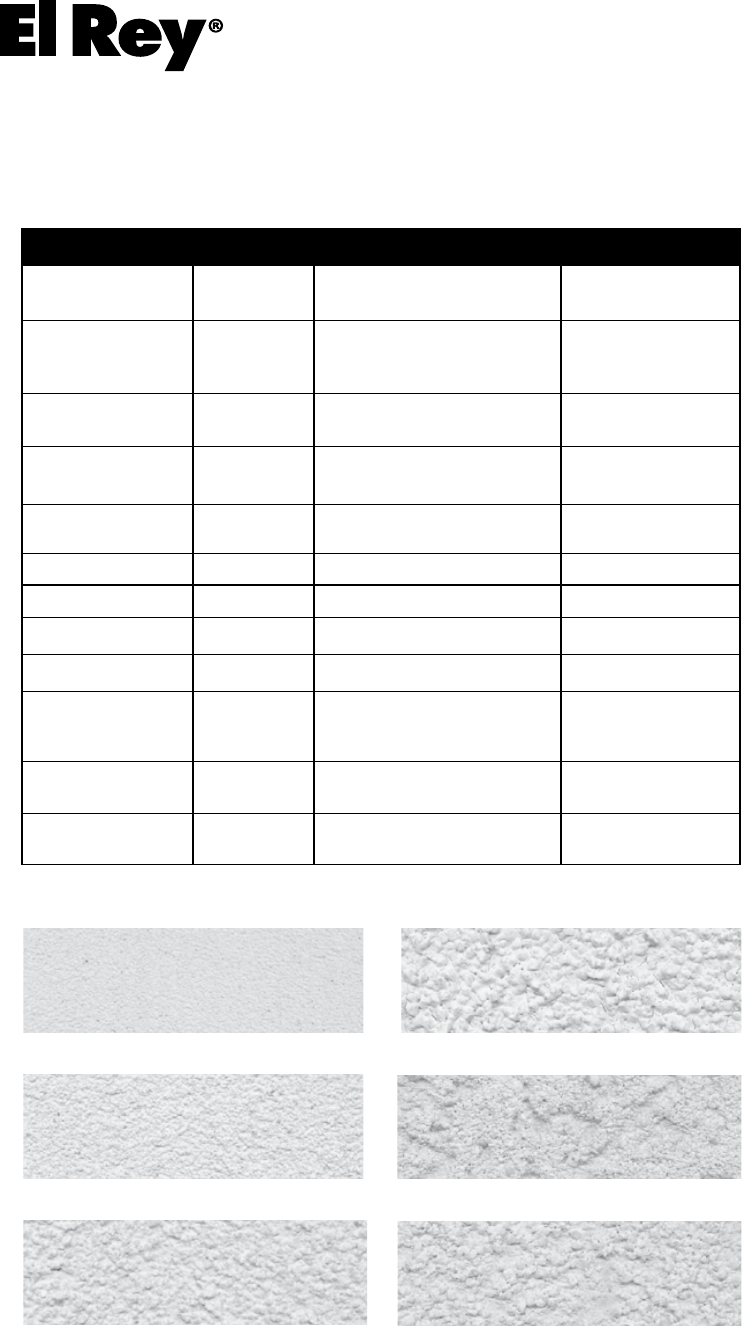

Perma-Flex DPR Acrylic Finishes

Smooth Coarse

Fine Swirl Fine

Medium MaxTex

MAXTEX

COARSE

SWIRL FINE

SMOOTH

MEDIUM

FINE