Instruction Manual

Table Of Contents

- System bus (CAN) for Lenze PLC devices

- This documentation is valid for ...

- Contents

- 1 Preface and general information

- 2 General information on the system bus (CAN)

- 2.1 Introduction

- 2.2 Interfaces of the Lenze PLCs for system bus connection

- 2.3 Identification of the nodes

- 2.4 Structure of the CAN telegram

- 2.5 Network management (NMT)

- 2.6 Transmission of process data

- 2.7 Transmitting parameter data

- 2.8 Free CAN objects

- 2.9 Application recommendations for the different CAN objects

- 2.10 Monitoring mechanisms

- 3 Configuration (system bus - CAN interface)

- 3.1 CAN baud rate

- 3.2 CAN boot-up

- 3.3 Node address (node ID)

- 3.4 Identifiers of the process data objects

- 3.5 Cycle time (CAN2_OUT/CAN3_OUT)

- 3.6 Delay time (CAN2_OUT/CAN3_OUT)

- 3.7 Synchronisation

- 3.8 Reset node

- 3.9 System bus management

- 3.10 Mapping indexes to codes

- 3.11 Remote parameterisation (gateway function)

- 3.12 Monitoring processes

- 3.13 Diagnostics

- 4 Configuration (AIF interface)

- 5 Configuration (FIF interface)

- 6 Configuration (CAN-AUX system bus interface)

- 7 CAN system blocks

- 8 FIF-CAN system blocks (only Drive PLC)

- 9 CAN-AUX system blocks (only ECSxA)

- 10 LenzeCanDrv.lib function library

- 10.1 Overview

- 10.2 Version identifiers of the function library

- 10.3 L_CanInit - initialising the CAN driver

- 10.4 L_CanClose - deactivating the CAN driver

- 10.5 L_CanGetStatus - querying the driver status

- 10.6 L_CanGetRelocCobId - querying the COB-ID range

- 10.7 L_CanPdoTransmit - transmitting a CAN object

- 10.8 L_CanPdoReceive - receiving a CAN object

- 11 LenzeCanDSxDrv.libfunction library

- 11.1 Overview

- 11.2 Version identifiers of the function library

- 11.3 L_CanDSxInitIndexCode - Configuration of index mapping

- 11.4 L_CanDSxOpen - initialising the CanDSx driver

- 11.5 L_CanDSxClose - deactivating the index mapping

- 11.6 L_CanDSxOpenHeartBeat - initialising a "Heartbeat"

- 11.7 L_CanDSxHeartBeat - carrying out a "Heartbeat"

- 11.8 L_CanDSxCloseHeartBeat - deactivating the "Heartbeat"

- 11.9 L_CanDSxOpenNodeGuarding - initialising the "Node Guarding"

- 11.10 L_CanDSxNodeGuarding - carrying out a "Node guarding"

- 11.11 L_CanDSxCloseNodeGuarding - deactivating the "Node Guarding"

- 12 Index

System bus (CAN) for Lenze PLC devices

General information

2−7

l

PLC−Systembus EN 2.0

2.6 Transmission of process data

Process data are data for control−oriented concerns, e. g. setpoints and actual values.

· Process data are transferred as so−called PDOs (Process Data Objects) with a high priority via

the system bus.

· Transmitting and receiving the process data is effected by the use of specific system blocks:

CAN

(integrated)

XCAN

(AIF interface)

FIF−CAN

(FIF interface)

For Drive PLC only!

CANaux

For ECSxA only!

Information

CAN1_IO AIF1_IO_AutomationInterface FIF_CAN1_IO CANaux1_IO Cyclic process data (sync−controlled)

CAN2_IO AIF2_IO_AutomationInterface FIF_CAN2_IO CANaux2_IO Event− or time−controlled process data

CAN3_IO AIF3_IO_AutomationInterface FIF_CAN3_IO CANaux3_IO Event− or time−controlled process data

Tip!

In the following subchapters you’ll receive further information on the CAN1_IO ... CAN3_IO process

data objects of the CAN interface. This information also applies to the process data objects of the

AIF−, FIF− and CAN−AUX interface!

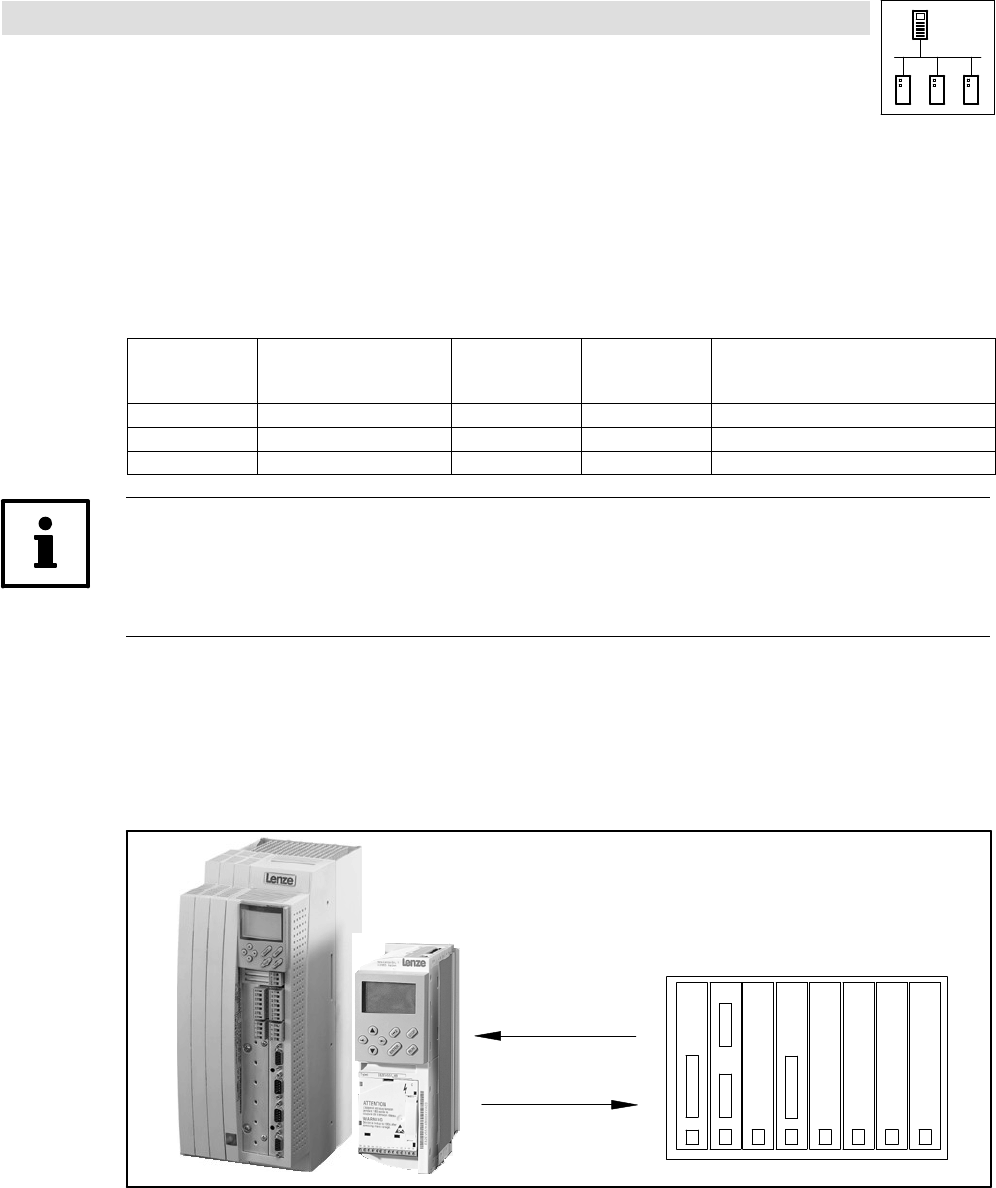

2.6.1 Process data channels

Process data channel 1: CAN1_IO

The CAN1_IO SB can be used for the data exchange of cyclic process data (e. g. setpoints and

actual values) with a higher−level host system.

cyclic process data (sync−controlled)

process data channel 1

CAN1_IN

CAN1_OUT

Host

Fig. 2−2 Process data channel 1 (CAN1_IO) for the cyclic data exchange