Instruction Manual

Table Of Contents

- System bus (CAN) for Lenze PLC devices

- This documentation is valid for ...

- Contents

- 1 Preface and general information

- 2 General information on the system bus (CAN)

- 2.1 Introduction

- 2.2 Interfaces of the Lenze PLCs for system bus connection

- 2.3 Identification of the nodes

- 2.4 Structure of the CAN telegram

- 2.5 Network management (NMT)

- 2.6 Transmission of process data

- 2.7 Transmitting parameter data

- 2.8 Free CAN objects

- 2.9 Application recommendations for the different CAN objects

- 2.10 Monitoring mechanisms

- 3 Configuration (system bus - CAN interface)

- 3.1 CAN baud rate

- 3.2 CAN boot-up

- 3.3 Node address (node ID)

- 3.4 Identifiers of the process data objects

- 3.5 Cycle time (CAN2_OUT/CAN3_OUT)

- 3.6 Delay time (CAN2_OUT/CAN3_OUT)

- 3.7 Synchronisation

- 3.8 Reset node

- 3.9 System bus management

- 3.10 Mapping indexes to codes

- 3.11 Remote parameterisation (gateway function)

- 3.12 Monitoring processes

- 3.13 Diagnostics

- 4 Configuration (AIF interface)

- 5 Configuration (FIF interface)

- 6 Configuration (CAN-AUX system bus interface)

- 7 CAN system blocks

- 8 FIF-CAN system blocks (only Drive PLC)

- 9 CAN-AUX system blocks (only ECSxA)

- 10 LenzeCanDrv.lib function library

- 10.1 Overview

- 10.2 Version identifiers of the function library

- 10.3 L_CanInit - initialising the CAN driver

- 10.4 L_CanClose - deactivating the CAN driver

- 10.5 L_CanGetStatus - querying the driver status

- 10.6 L_CanGetRelocCobId - querying the COB-ID range

- 10.7 L_CanPdoTransmit - transmitting a CAN object

- 10.8 L_CanPdoReceive - receiving a CAN object

- 11 LenzeCanDSxDrv.libfunction library

- 11.1 Overview

- 11.2 Version identifiers of the function library

- 11.3 L_CanDSxInitIndexCode - Configuration of index mapping

- 11.4 L_CanDSxOpen - initialising the CanDSx driver

- 11.5 L_CanDSxClose - deactivating the index mapping

- 11.6 L_CanDSxOpenHeartBeat - initialising a "Heartbeat"

- 11.7 L_CanDSxHeartBeat - carrying out a "Heartbeat"

- 11.8 L_CanDSxCloseHeartBeat - deactivating the "Heartbeat"

- 11.9 L_CanDSxOpenNodeGuarding - initialising the "Node Guarding"

- 11.10 L_CanDSxNodeGuarding - carrying out a "Node guarding"

- 11.11 L_CanDSxCloseNodeGuarding - deactivating the "Node Guarding"

- 12 Index

System bus (CAN) for Lenze PLC devices

General information

2−13

l

PLC−Systembus EN 2.0

2.7.1.3 Addressing the parameter (index/subindex)

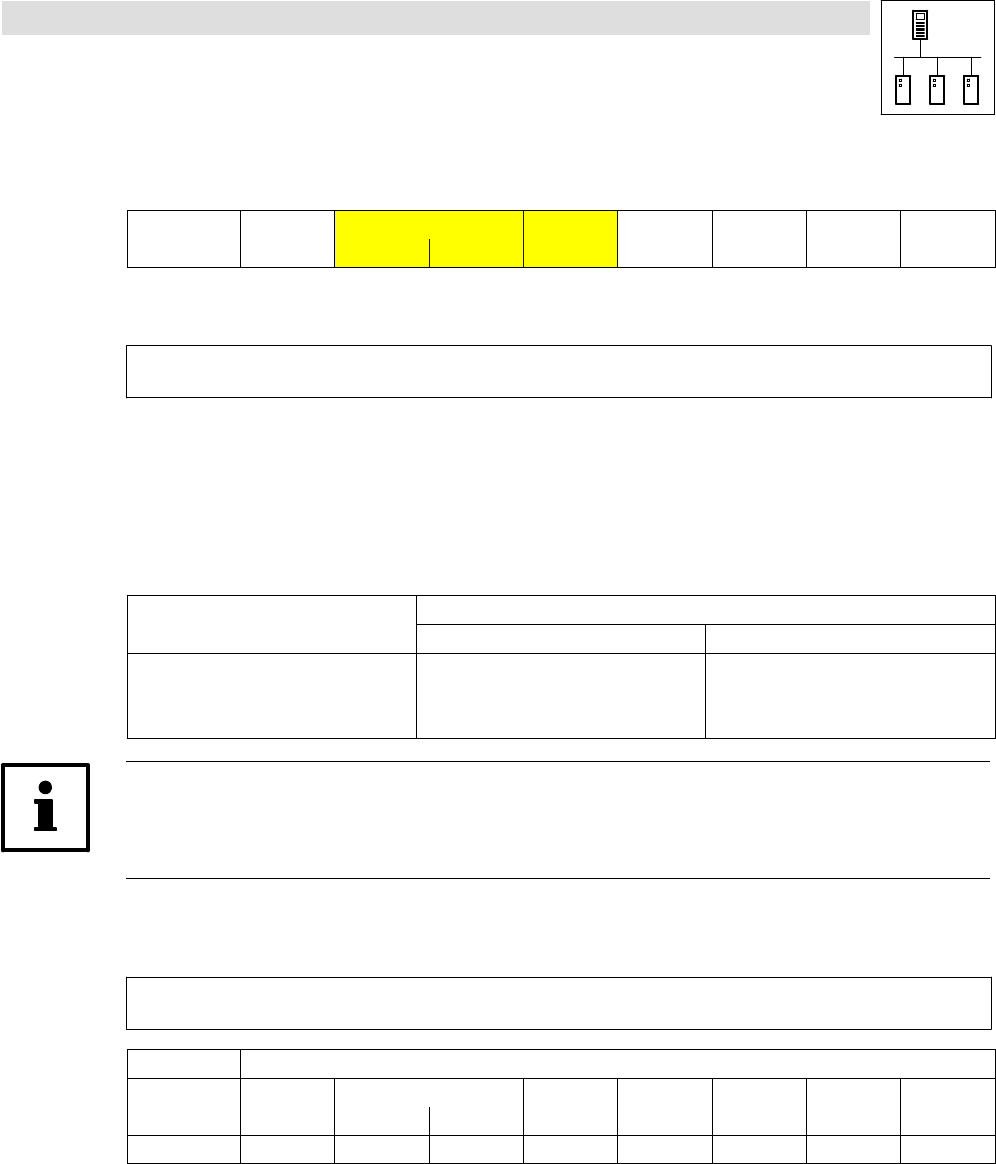

Identifier

Command

code

Index

Subindex Data 1 Data 2 Data 3 Data 4

Low byte High byte

The addressing of the parameter or of the Lenze code which is to be read or written is effected via

the index of the telegram:

Index + 24575 * Lenze code number

· The value for the index is to be entered divided into a low and a high byte in the left−justified

Intel format (see example).

· If a subcode is to be addressed, enter the number of the respective subcode in the subindex

of the telegram.

· For codes without subcodes, the subindex always receives the value "0".

· The index for Lenze codes is between 40C0

hex

(16576) and 5FFF

hex

(24575).

Lenze code Index

dec hex

C0000 24575 5FFF

... ... ...

C7999 16576 40C0

Tip!

For converting a code number to the corresponding index, the function L_FUNCodeIndexConv in

the LenzeDrive.lib function library is provided to you.

Example:

Subcode 1 of code C0168 (fault messages) is to be addressed:

Index + 24575 * 168 + 24407 + 5F57

hex

11bit 8 bytes user data

Identifier

Command

code

Index

Subindex Data 1 Data 2 Data 3 Data 4

Low byte High byte

57

hex

5Fhex 1

hex