Datasheet

LT1117/LT1117-2.85

LT1117-3.3/LT1117-5

8

1117fd

APPLICATIONS INFORMATION

Output Voltage

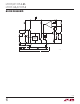

The LT1117 develops a 1.25V reference voltage between the

output and the adjust terminal (see Figure 2). By placing a

resistor between these two terminals, a constant current

is caused to flow through R1 and down through R2 to

set the overall output voltage. Normally this current is

chosen to be the specified minimum load current of 10mA.

Because I

ADJ

is very small and constant when compared

to the current through R1, it represents a small error and

can usually be ignored. For fixed voltage devices R1 and

R2 are included in the device.

1117 F02

R2

R1

V

OUT

V

IN

V

REF

I

ADJ

50µA

LT1117

IN

ADJ

OUT

V

OUT

= V

REF

1 + + I

ADJ

R2

R2

—

R1

+

Figure 2. Basic Adjustable Regulator

Load Regulation

Because the LT1117 is a 3-terminal device, it is not possible

to provide true remote load sensing. Load regulation will be

limited by the resistance of the wire connecting the regulator

to the load. The data sheet specification for load regulation

is measured at the output pin of the device. Negative side

sensing is a true Kelvin connection, with the bottom of the

output divider returned to the negative side of the load.

Although it may not be immediately obvious, best load

regulation is obtained when the top of the resistor divider

(R1) is returned directly to the output pin of the device,

not to the load. This is illustrated in Figure 3. Connected

as shown, R

P

is not multiplied by the divider ratio. If R1

were connected to the load, the effective resistance between

the regulator and the load would be:

R

RR

R

R

PP

×

+

=

21

1

, Parasitic Line Resistance

1117 F03

R2

R1

V

IN

R

P

PARASITIC

LINE RESISTANCE

R

L

CONNECT

R1 TO CASE

CONNECT

R2 TO LOAD

LT1117

IN

ADJ

OUT

Figure 3. Connections for Best Load Regulation

For fixed voltage devices the top of R1 is internally Kelvin

connected, and the ground pin can be used for negative

side sensing.

Thermal Considerations

LT1117 series regulators have internal thermal limiting

circuitry designed to protect the device during overload

conditions. For continuous normal load conditions however,

the maximum junction temperature rating of 125°C must

not be exceeded.

It is important to give careful consideration to all sources

of thermal resistance from junction to ambient. For

the SOT-223 package, which is designed to be surface

mounted, additional heat sources mounted near the device

must also be considered. Heat sinking is accomplished

using the heat spreading capability of the PC board and

its copper traces. The thermal resistance of the LT1117 is

15°C/W from the junction to the tab. Thermal resistances

from tab to ambient can be as low as 30°C/W. The total

thermal resistance from junction to ambient can be as low

as 45°C/W. This requires a reasonable sized PC board with

at least one layer of copper to spread the heat across the

board and couple it into the surrounding air.