User Guide

The flexible jacketed cord assembly mounted to the pump must

not be modified in any way, with the exception of shortening the

cord to fit into a control panel. Any splice between the pump and

the control panel must be made within a junction box and mount-

ed outside of the basin, and comply with the National Electrical

Code. Do not use the power cord for lifting the pump.

The pump motor is equipped with an automatic resetting thermal

protector and may restart unexpectedly. Protector tripping is an

indication of motor overloading as a result of operating the pump

at low heads (low discharge restriction), excessively high or low

voltage, inadequate wiring, incorrect motor connections, or a defective

motor or pump.

1. Read all instructions and Safety Guidelines thoroughly. Failure

to follow the guidelines and instructions could result in serious

bodily injury and/or property damage.

2. DO NOT USE TO PUMP FLAMMABLE OR EXPLOSIVE FLUIDS

SUCH AS GASOLINE, FUEL OIL, KEROSENE, ETC. DO

NOT USE IN EXPLOSIVE ATMOSPHERES OR HAZARDOUS

LOCATIONS AS CLASSIFIED BY NEC, ANSI/NFPA70. FAILURE

TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

3. During normal operation the pump is immersed in water. Also,

during rain storms, water may be present in the surrounding

area of the pump. Caution must be used to prevent bodily injury

when working near the pump:

a. The plug must be removed from the receptacle prior to

touching, servicing or repairing the pump.

b. To minimize possible fatal electrical shock hazard, extreme

care should be used when changing fuses. Do not stand in

water while changing fuses or insert your finger into the fuse

socket.

4. Do not run the pump in a dry basin. If the pump is run in a dry

basin, the surface temperature of the pump will rise to a high

level. This high level could cause skin burns if the pump is

touched and will cause serious damage to your pump.

5. Do not oil the motor. The pump housing is sealed. A high

grade high temperature dielectric oil devoid of water has been

put into the motor housing at the factory. Use of other oil could

cause serious electric shock and/or permanent damage to

the pump.

6. This pump’s motor housing is filled with a dielectric lubricant

at the factory for optimum motor heat transfer and lifetime

lubrication of the bearings. Use of any other lubricant could

cause damage and void the warranty. This lubricant is non-

toxic; however, if it escapes the motor housing, it should be

removed from the surface quickly by placing newspapers or

other absorbent material on the water surface to soak it up, so

aquatic life is undisturbed.

7. Allow pump to cool (4 hours minimum) prior to servicing. The

oil is pressurized at elevated temperatures.

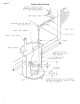

INSTALLATION

Pump must be installed in a suitable basin which is at least 18"

in diameter and 24" deep, and installed in accordance with local

electrical and plumbing codes.

The HT-10E Series Effluent Pumps feature a 1-1/2" female NPT

discharge.

Pump can be installed with materials capable of withstanding 200°F

water. Proper adapters are required to connect piping to pump.

Pump must be placed with its base on a hard level surface. Never

place pump directly on clay, earth or gravel surfaces.

A check valve must be used in the discharge line to prevent back

flow of liquid into the basin. The check valve should be a free flow

valve that will easily pass solids.

CAUTION: For best performance of check valves, when handling

solids install in a horizontal position or at an angle of no more than

45°. Do not install check valve in a vertical position, as solids may

settle in valve and prevent opening on start-up.

When a check valve is used drill a 3/16" hole in the discharge pipe

approximately 1" to 2" above the pump discharge connection and

below check valve to prevent air locking of the pump.

WIRING

Check local electrical and building codes before installation. The

installation must be in accordance with their regulations as well as

the most recent National Electrical Code (NEC).

To conform to the National Electrical Code all pumps must be

wired with 14 AWG or larger wire. For runs to 250', 14 AWG wire

is sufficient. For longer runs, consult a qualified electrician or the

factory.

Pump should be connected or wired to its own circuit with no other

outlets or equipment in the circuit line. Fuses and circuit breaker

should be of ample capacity in the electrical circuit. See chart below.

H.P. VOLTAGE

FUSE OR CIRCUIT

BREAKER AMPS

1/2 115 20

FLOAT SWITCH LEVEL CONTROL

The FS series pumps are equipped with an integral float switch

level control for automatic operation. This level control uses a

mechanical switch sealed in a specially designed high temperature

float cylinder.

When the level rises in the basin, the cylinder floats up with the

level. When the cylinder position is at an angle of about 45°, the

pump starts.

As the level draws down, the cylinder floats down and when it is

again at an angle of about 45°, the pump stops.

NOTE: BE CERTAIN PUMP IS SECURE IN BASIN AND CYLINDER

FLOATS UNOBSTRUCTED WITHOUT TOUCHING THE BASIN

WALLS OR PLUMBING.

2

Figure 2.