User Guide

3

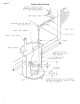

REMOTE FLOAT SWITCH INSTALLATION

1. The float switch consists of three parts: a) mechanical switch;

b) cord clamp; c) clamp screw.

NOTE: If screw is lost, use a #10-24 x 1/2" long tapping

screw.

2. Attach cord clamp to pump cover as shown in Figure 1. The

clamp must be positioned as shown to allow free operation of

float. Be sure to locate pump and switch power cords away

from switch float.

3. A 5" tether length is recommended. When a tether length of 5"

is used, a minimum basin diameter of 18" is recommended.

The tether length is measured as shown in Figure 3.

4. After desired tether length is established, hand-tighten clamp

screw.

5. TESTING: Plug switch into outlet without water in basin. Lift

float and watch for pump to operate. Do not run pump for

more than 5 seconds.

OPERATION

TESTING PUMP OPERATION

FS SERIES AUTOMATIC PUMPS

1. These pumps are equipped with a float-operated switch.

2. When these pumps are installed in a basin with a sealed

cover, switch operation cannot be observed. The sump cover

usually will have a spare hole that is plugged with a rubber

plug. This plug can be removed and switch operation can be

observed.

3. Run water into pump until pump starts.

4. Be sure gate valve in discharge line is open.

5. Allow pump to operate through several on-off cycles.

MANUAL PUMPS

The pump cord for these pumps can be plugged directly into a

properly grounded receptacle with voltage consistent with pump

nameplate for continuous pump operation.

CAUTION: This type of operation should be used only for emer-

gency use or when a large volume of water is to be pumped.

Pump must not be allowed to run dry. If pump is run dry, it may

damage pump an void the warranty.

MAINTENANCE AND SERVICE

If pump does not operate properly, consult the Troubleshooting

Chart. If trouble cannot be located with these steps shown, con-

sult your pump dealer or take pump to a Little Giant authorized

service center.

NOTE: Relay Cover Mounting Screws (item #23) requires 15-20

in-lbs. torque.

CAUTION: When working on pump or switch, always unplug

pump power cord in addition to removing fuse or shutting off circuit

breaker before working on pump.

CLEANING IMPELLER AND VOLUTE

WARNING: DO NOT REMOVE THE 3 SOCKET-HEAD CAP SCREWS.

THE MOTOR SECTION OF YOUR PUMP IS PERMANENTLY

LUBRICATED WITH DIELECTRIC OIL AND SEALED AT THE

FACTORY. REMOVAL OF THESE SOCKET-HEAD CAP SCREWS

BY ANYONE OTHER THAN AN AUTHORIZED LITTLE GIANT SERVICE

CENTER WILL BREAK THIS SEAL AND VOID THE WARRANTY.

1. On 10E Series Effluent pumps: Remove 5 screws (item 18 on

parts list) that hold screen base and base plate to volute/plate.

2. Clean impeller and volute passage. Do not use strong solvents

on impeller.

3. Be sure impeller turns freely after cleaning.

4. WARNING: DO NOT REMOVE IMPELLER. WARRANTY IS VOID

IF MOTOR HOUSING, IMPELLER OR SEALS HAVE BEEN

REMOVED.

ANY REPAIR ON MOTOR MUST BE DONE BY AN AUTHORIZED

LITTLE GIANT SERVICE CENTER.