Operator's manual

14

Gas sampling and gas conditioning technology 4-1.1-ME

265

6

23

5

9

8

14

10 13

2120

Schnitt A-A

16

17

15 1924

1.2

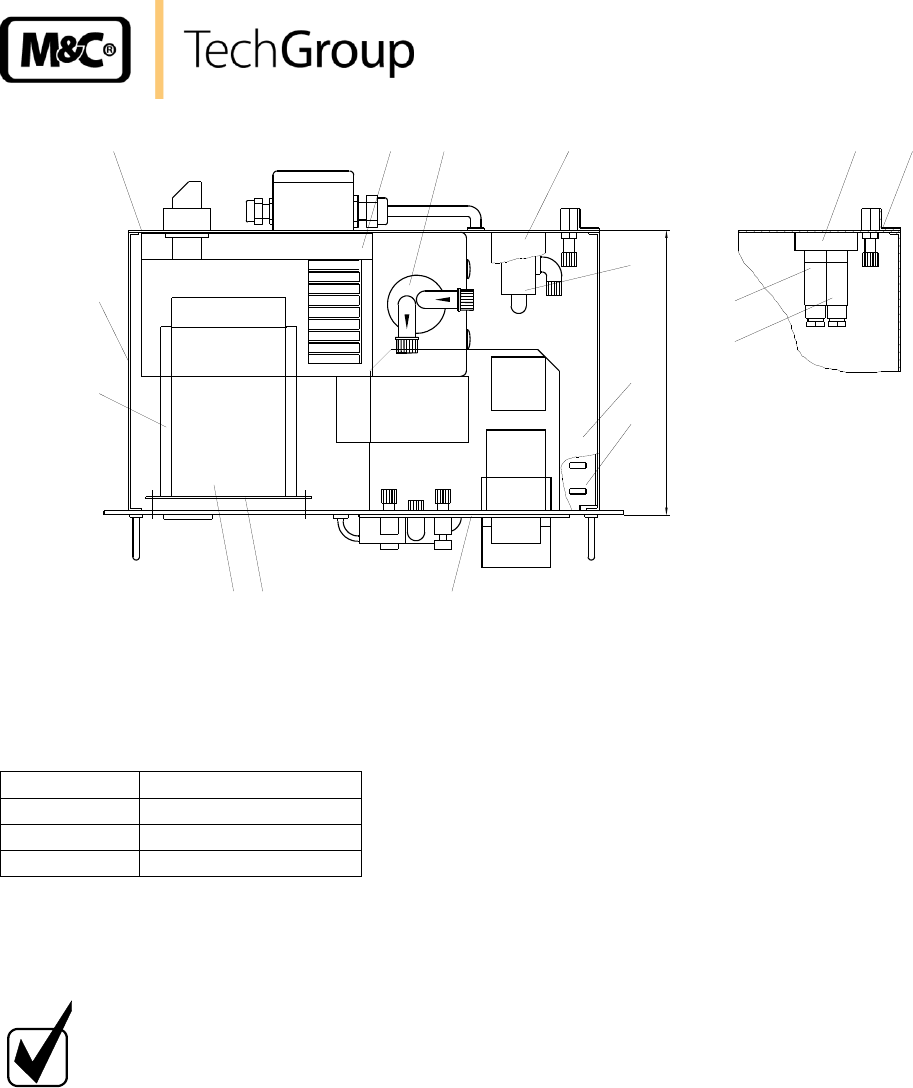

Figure 4 Components mounted in the 19“ rack housing

The gas cooler (10) is fixed on the back panel of the 19“ rack housing. With respect to the maximum

flow rate required, the following versions are available:

Cooler

max. flow rate [l/h]

ECP 1000

140

ECP 2000

2 x 140

ECP 3000

350

Ambient air enters the chassis through the slots in the bottom (8) and top plate (9) of the 19“ rack

housing. This allows ventilation and cooling of the internal components including the gas cooler.

The cooler fan exhausts air out of the cut out in the side wall (6) of the 19“ rack housing.

NOTE!

The PSS must be stored in a weather-protected frost-free area ! Allows ade-

quate ventilation around the chassis !

The 3-way solenoid valve (14), for switching of the sample and test gas, is mounted in a special holder

(13) on the back panel (5).

Sectional view A-A in illustration 4 shows the two 2-way solenoid valves (16) and (17), for zero and

span gas. They are mounted with valve block (15) below the valve (14) on the back panel of the 19"

rack housing. Additional 3 span gas valves are possible as option (see page 8). The span gas valves

are preselected by snap switch 1.5 (Fig. 1).

The combined card for flow- and liquid alarm LFC-2 (20) is connected on the main circuit board (21).

The CSS is protected by fuse (F1= 2A, see wiring diagram in appendix).