Manual

7/9/2013 CLUTCH_THRUSHAFT_AIR_HD_MANUAL Page 3 of 4

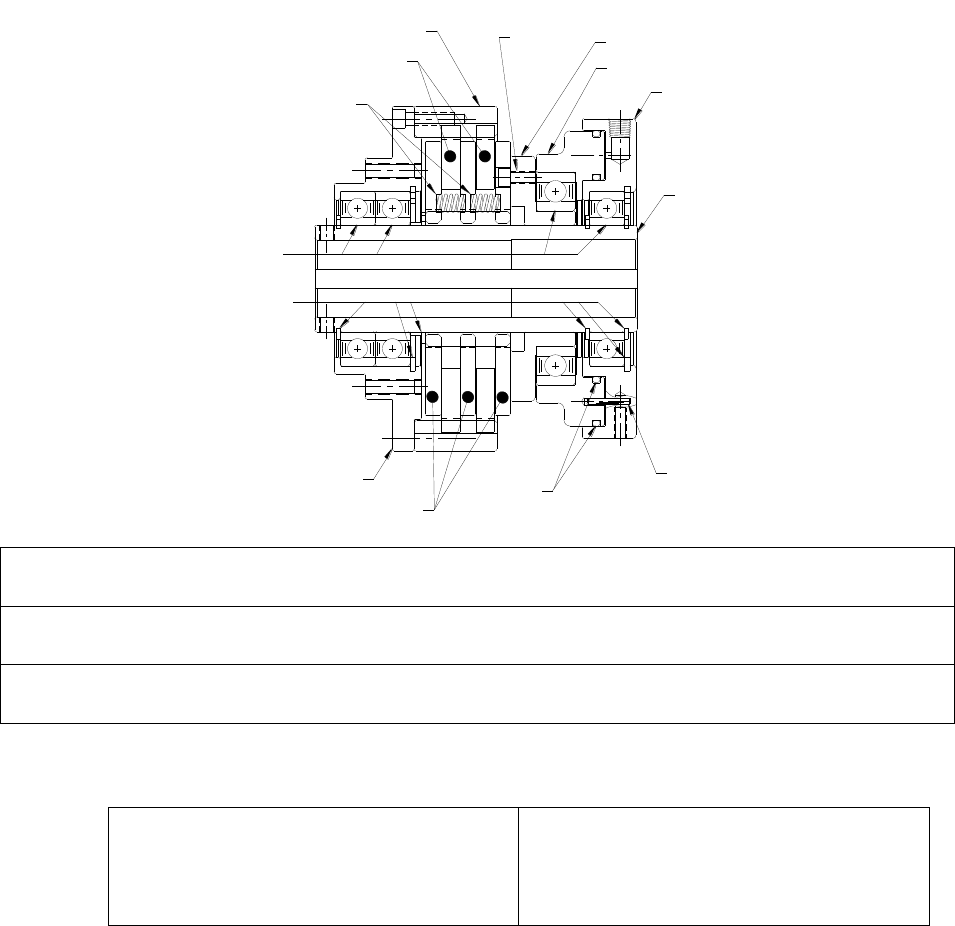

RING GEAR

PIN

O-RING

DRIVE DISC

SLEEVE

RETAINER RING

BEARING

SPRING

FRICTION DISC

SCREW

CONE

PISTON

CYLINDER

DRIVE HUB

IV. Clutch Operation

The maximum operating pressure should not exceed 80 PSI. Operation at pressures

greater than that required for proper function will decrease the life of the bearings.

Special Note Regarding Friction Disc Contamination:

The friction material used in this product will absorb oil, water, chemicals and other

contaminants. Depending on the type of contamination, clutch may either seize up

entirely or lose torque capacity. If friction discs become contaminated, they should be

replaced. See repair kit ordering information below.

V. Routine Maintenance

When installed and operated according to the preceding guidelines, Mach III Clutch

products should require little or no routine maintenance. A repair kit is available which

contains all parts subject to typical wear: friction discs, springs and O-rings.

VI. Parts diagram

Repair Kit:

Part number = Clutch Product Number + “-RPRK” (e.g. C5A2K-STH-RPRK)

Additional

Parts:

Contact Mach III to obtain a complete listing of additional parts kits available for

your specific clutch. Please reference product number when calling or e-mailing.

Repair

services:

Factory repair is available. A return materials authorization (RMA) number must

be obtained prior to sending any unit in for repair

VII. Repair Kit Installation Procedure

Tools Required

Hex Wrench Set

Rubber Mallet or similar soft face hammer

Retainer (snap) Ring Pliers

Scraper

Compounds Required

Grease

O-ring Lubricant

Loctite

®

#609 Retaining Compound

Anti-Seize Lubricant (for re-installation)

(Continued on next page)