Instruction manual

When using synthetic resin cutting discs, always ob-

serve the following:

CAUTION:

- Synthetic resin cutting discs can absorb moisture. This

moisture can cause the disc to become unbalanced at high

speed. This imbalance can cause the disc to break.

- Do not cool resin cutting discs with water or other fiuids.

- Do not expose resin cutting discs to high humidity or

rain!

Do not use resin cutting discs past their use-by date (expira-

tion date)! The date (quarter and year) is stamped on the disc's

arbor ring.

EXAMPLE: 04 / 2014

This cutting disc can be used through the end of the fourth quarter

of 2014, if properly stored and correctly used.

Cutting metals

IMPORTANT!

Always wear approved respiratory protection!

Materials that can release toxic substances may be cut only

after notifying the proper authorities and under their supervi-

sion or that of a person appointed by them.

CAUTION!

The rapid rotation of the cutting disc heats metal and melts it

at the point of contact. Swing the guard as far down as pos-

sible (19) in order to direct the stream of sparks forward, away

from the operator (fi re hazard).

- Determine the cut line, mark the cut and apply the disc to the

material at moderate speed, to cut a guide groove before going

to top speed and applying more pressure to the Power Cut.

- Keep the disc straight and vertical. Do not tip it, as this can

break it.

- The best way to get a good, clean cut is to pull or move the

Power Cut back and forth. Do not simply press the disc into

the material.

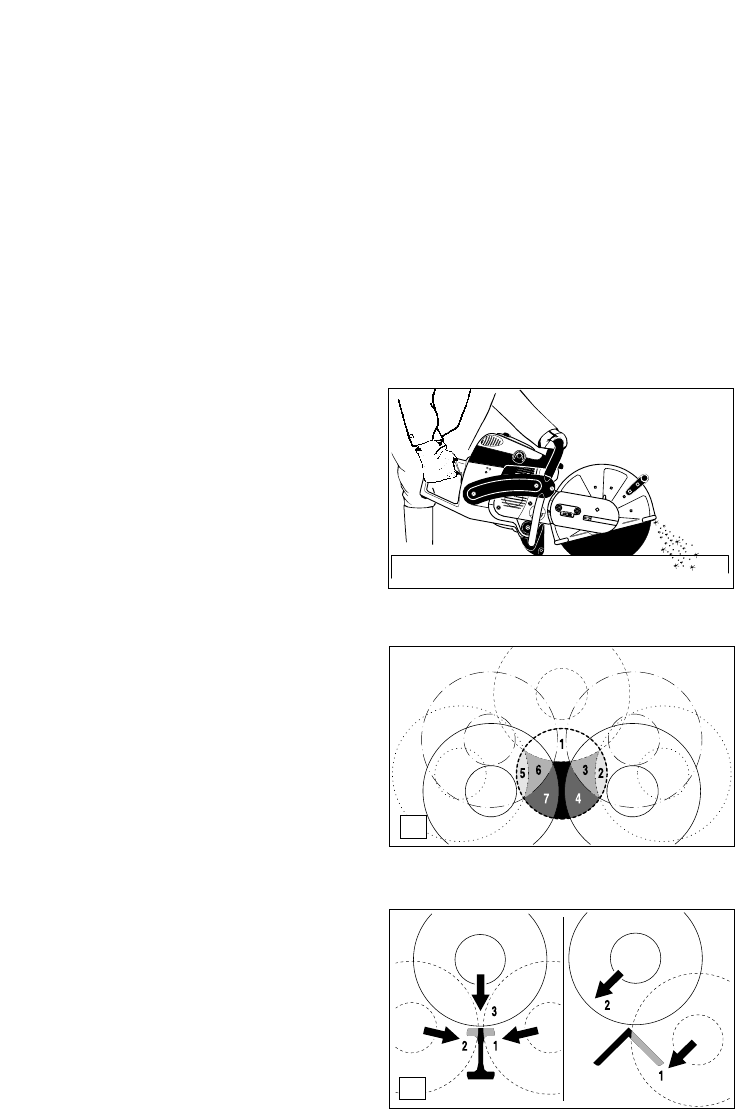

- Thick round stock is best cut in stages (20).

- Thin tubing and pipes can be cut with a simple downward

cut.

- Cut large-diameter pipes as for round stock. To prevent tipping

and for better control, do not let the disc sink too deeply into

the material. Instead, always cut shallow around the whole

piece.

- Worn discs have a smaller diameter than new discs, so that at

the same engine speed they have a lower effective circumfer-

ential speed and therefore do not cut as well.

- Cut I-beams and L-bars in steps; see Figure 21.

- Cut bands and plates like pipes: along the wide side with a long

cut.

- When cutting material under stress (supported material or mate-

rial in structures), always make a notch in the thrust (pressure)

side, and then cut from the tension side, so that the disc does

not lock in. Secure cutoff material from falling!

CAUTION!

If there is a chance that the material is under stress, be pre-

pared for it to kick back. Make sure you can get out of the

way if you have to!

Be particularly careful in scrap-metal yards, junkyards, at ac-

cident sites, and with haphazard piles of material. Precariously

balanced pieces or pieces under stress can act in unpredictable

ways, and may slide, jump out, or burst. Secure cutoff material

from falling! Always exercise extreme caution and use only

equipment that is in perfect working order.

Observe the accident-prevention rules and regulations of your

employer and/or insurance organization.

Cutting masonry and concrete

IMPORTANT!

Always wear approved respiratory protection!

Asbestos and other materials that can release toxic sub-

stances may be cut only after notifying the proper authorities

and under their supervision or that of a person appointed

by them. When cutting prestressed and reinforced concrete

piles, follow the instructions and standards of the respon-

sible authorities or the builder of the structural member.

Reinforcement rods must be cut in the prescribed sequence

and in accordance with applicable safety regulations.

NOTE:

Mortar, stone, and concrete develop large quantities of dust during

cutting. To increase the lifetime of the cutting disc (by cooling),

to improve visibility, and to avoid excessive dust creation, we

strongly recommend wet cutting instead of dry cutting.

19

20

21

8

Kada koristite diskove za otsecanje od sintetičkih smola pazite

na sledeće:

PAŽNJA:

- Diskovi za otsecanje od sintetičkih smola imaju osobinu

da apsorbuju vlagu. Apsorbovana vlaga izaziva neuram-

noteženost pri velikim brzinama. Ovo izaziva lomljenje diska.

- Ne hladite diskove sa vodom ili sa drugom tečnošću.

- Ne izlažite diskove na vlagu ili na kišu!

- Diskove za otsecanje od sintetičkih smola ne koristite posle

roka za korišćenje! Propisani rok (kvartal i godina) je napisan

na prstenu na nasadnom otvoru diska.

PRIMER: 04 / 2014

Ovaj disk za otsecanje može da se koristi do kraja 4 kvartala 2014

godine, ako je propisno skladišćen i pravilno korišćen.

Sečenje metala

VAŽNO!

Uvek da nosite propisanu masku za disanje!

Materijali koji mogu da proizvedu otrovne supstance mogu da se

seku samo posle izveštavanja nadležnih organa i pod njihovim

nadzorom ili pod nadzorom lica imenovanog od njih.

PAŽNJA!

Velike brzine diskova zagrevaju metal i tope ga u tačku dodira.

Spustite štitnik što je moguće niže (19), da bi usmerili razletalu

varnicu nasuprot rukovaoca (opasnost od požara).

- Odredite i označite liniju sečenja i sa smanjenom brzinom diska

prodrite u materijal, da bi isekli osnovni rez, pre nego što povećate

brzinu i primenite veći pritisak na Power Cut.

- Držite disk pravo i vertikalno. Nemojte da ga okrećete da ga ne

bi slomili.

- Najbolji način da dobijete dobar, čisti rez je da gurate ili da vučete

Power Cut nazad ili napred. Nemojte samo da pritiskate disk u

materijal.

- Velike kružne komade secite postepeno (20).

- Tanke cevi secite sa vertikalnim posmacima.

- Cevi sa velikim prečnicima seku se kao i veliki kružni komadi. Za

izbegavanje izvijanja i za bolju kontrolu ne dozvolite da disk potone

duboko u materijal. Uvek da sečete po obimu radnog komada.

- Istrošeni diskovi imaju manji prečnik od novih i s time i manju

perifernu brzinu pri istom broju obrtaja motora. Zbog toga oni ne

seku dobro.

- I- nosače i L-prole secite postepeno; vidi crtež 21.

- Čelične trake i ploče secite kao i cevi; po dužini široke strane sa

dugačkim rezovima.

- Kada sečete napregnute materijale (opterećeni ili ugrađeni

materijali) prvo zasecite klin sa zbijene strane (pritisnute), a zatim

secite sa istegnute strane, čime disk neće da se zaglavi. Otpadni

materijal obezbedite od padanja!

PAŽNJA!

Ako postoji opasnost da je materijal napregnut, budite spremni za

povratni udarac. Budite spremni da ga izbegnete, kada se pojavi!

Budite pažljivi i imajte na umu da mogu da se pojave razletali

otpaci od metala. Neizvesno balansirani ili napregnuti komadi

mogu da krenu u neočekivanom pravcu i mogu da proklize,

da otskoče ili da naprsnu. Obezbedite otsečene materijale od

padanja. Radite sa velikom pažnjom i koristite opremu koja je u

odličnom radnom stanju.

Primenjujte pravila za izbegavanje nesreća i propise od

poslodavca i/ili od osiguravajućih kompanija.

Sečenje maltera i betona

VAŽNO!

Uvek da koristite respiratornu zaštitu!

Azbest ili drugi materijali koji mogu da proizvedu otrovne

supstance mogu da se seku samo posle izvešća nadležnih organa

i pod njihovim nadzorom ili pod nadzorom lica imenovanog od

njih. Kada sečete prednapregnute ili ojačane armirane betonske

šipke, sledite uputstva i standarde nadležnih organa ili graditelja

strukture. Armirane šipke moraju da se seku po propisanom

redosledu i prema bezbednosnim propisima.

ZABELEŠKA:

Malter, kamen i beton, dok se seku, proizvode veliku količinu prašine.

Da bi povećali trajnost diska (sa hlađenjem), da bi poboljšali vidljivost i

da bi izbegli intenzivno izdvajanje prašine, preporučujemo da koristite

mokro umesto suvog sečenja.