Use and Care Manual

3

110522-3

MAINTENANCE

WARNING:

Before doing any maintenance be sure power is off and unit is unplugged. This is for your safety.

ROUTINE MAINTENANCE

WEEKLY:

1. Drain and replenish water from the cooler at least weekly. This keeps the water in the pan fresh and helps prevent scale

and mineral deposit accumulation on the pads.

AT THE END OF THE SEASON OR DURING EXTENDED PERIODS OF NON-USE:

1. Completely drain the reservoir and disconnect water supply. Ensure no water remains during freezing weather.

2. Unplug unit from power supply.

3. Cover unit or store inside when not in use.

ANNUAL MAINTENANCE

1. Change Pads. Pads should be replaced once or twice a season, depending upon the length of the season. At the beginning and at

mid season a clean pad is more absorbent and effi cient and will deliver substantially cooler air.

a. Remove louvered side.

b. Unhook the wire pad holder.

c. Replace pad (some trimming may be necessary.)

d. Reattach the wire pad holders and replace louvered sides.

REMOVE BASE

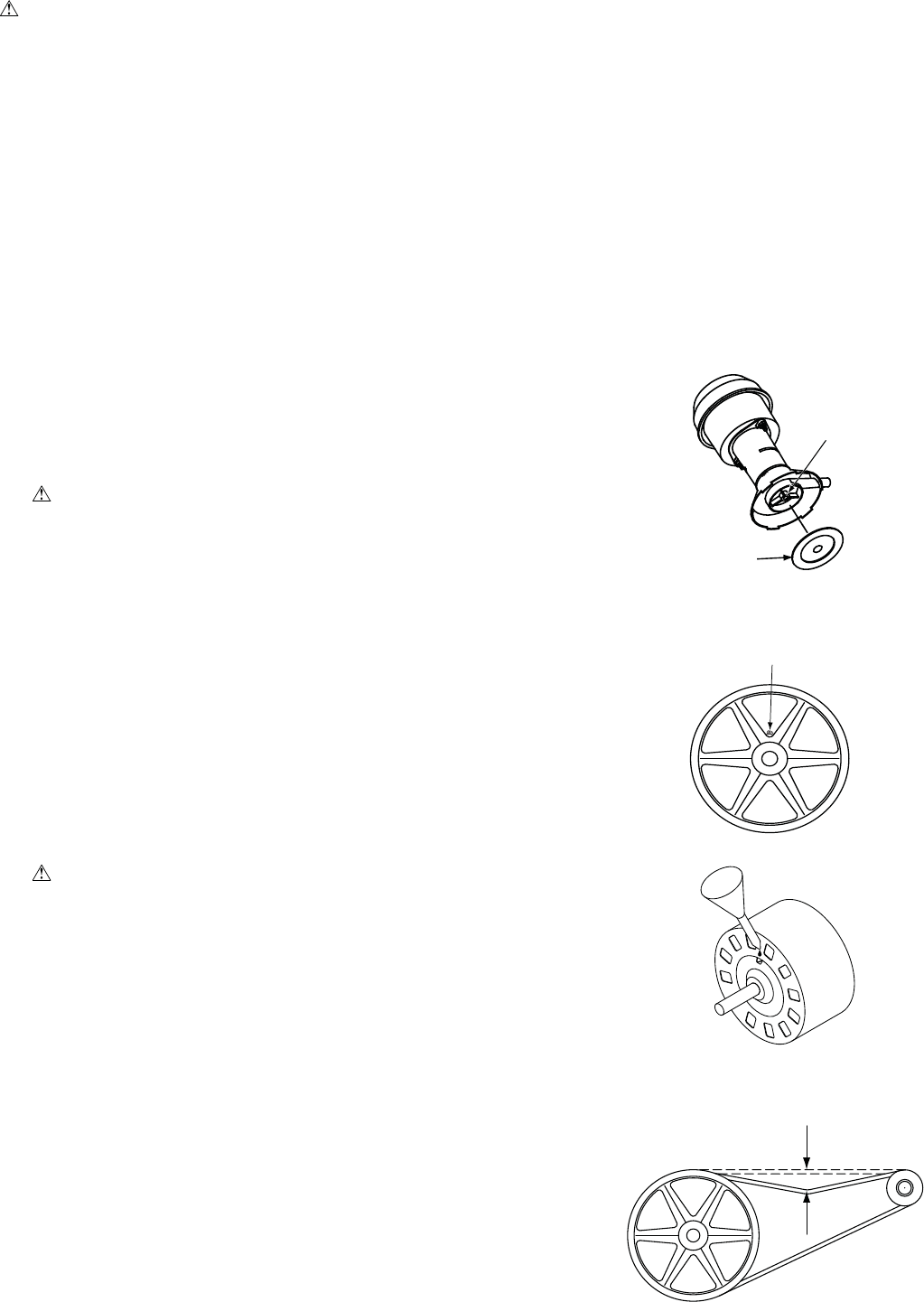

IMPELLER

BLOWER BEARING

OIL PORT

3 LB. PRESSURE

3/4”

Oil Motor

NOTE: These units come with synthetic cooling pads. Although aspen pads

can be used in these coolers, we recommend using synthetic pads

over aspen

pads if using indoors, to reduce the incidence of shedding.

2. Clean pump. Cleaning the pump is necessary once a year at start-up.

CAUTION: Before cleaning pump, ensure unit is turned off and unit and

pump are unplugged.

a. Remove the pump from the mount slot.

b. Remove the base of the pump.

c. Clean the pump and turn the impeller to ensure free operation

d. Remove the pump spout and check for any blockage.

e. After cleaning, reinstall the base onto the pump. Press fi rmly to make sure it

is secure.

f. Reattach the pump to the mount in the cooler using the plastic retainer to

ensure that the pump will not overturn.

NOTE: Do not forget to replace the spout and water delivery tube onto the

pump outlet.

3. Oil blower bearings (MMBT14 only). The blower bearings should be oiled with a

few drops of non-detergent 20/30 weight at least oil once each year.

4. Oil motor bearing (MMBT12 only). The cooler motor in this unit should be oiled

with a few drops of non-detergent 20/30 weight oil once each year. The oil ports

are located on each side of the motor.

CAUTION: Do not over oil. Over oiling can cause motor burn out, due to

excessive oil getting into motor winding.

5. Check belt and belt tension. This applies only to model MMBT14 which is belt

driven. Model MMBT12 has a direct drive motor. Check the belt for any cracks or

wear and replace if necessary. Check the tension on the belt. A 3 lb. force should

defl ect the belt 3/4 inches. Readjust belt if needed.

By following the operating, installation, and maintenance suggestions as outlined,

you can get many years of effi cient and satisfactory service from your cooler. In the

event additional information is desired, your dealer will be more than glad to assist

you in every possible way.