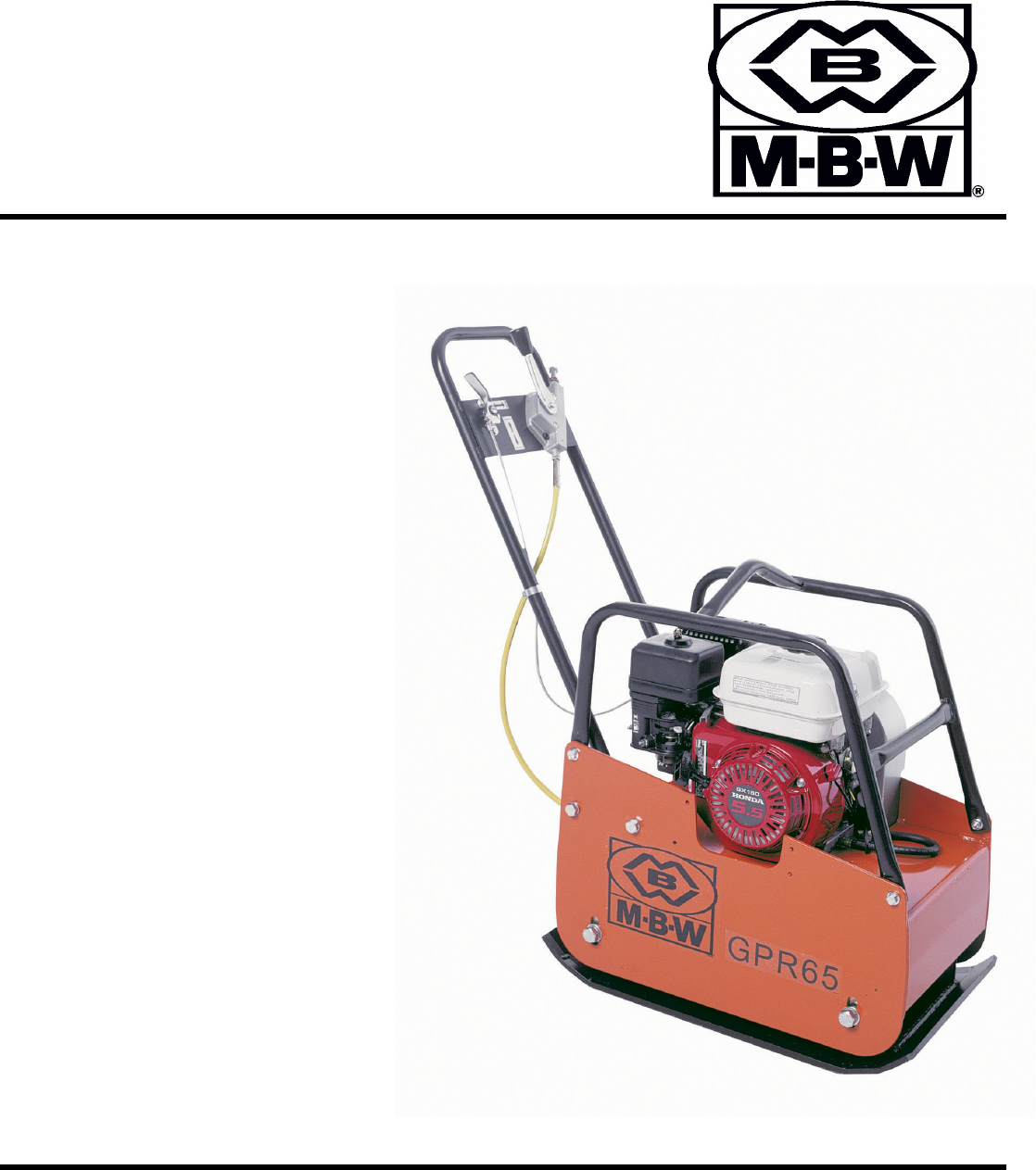

OPERATOR’S SAFETY AND SERVICE MANUAL GPR65, GPR68 & GPR77 This manual covers the following serial numbers and higher for each model listed: GPR65. . . . . . . . . . . . . . . . . . . . 6500001 GPR68. . . . . . . . . . . . . . . . . . . . 6800001 GPR77. . . . . . . . . . . . . . . . . . . . 7700010 REVERSIBLE PLATES MBW, Inc. MBW (UK) Ltd. MBW FRANCE S.A.R.L. 250 Hartford Rd • PO Box 440 Slinger, WI 53086-0440 Phone: (262) 644-5234 Fax: (262) 644-5169 Email: mbw@mbw.com Website: www.mbw.

TABLE OF CONTENTS Safety Information . . . . . . . . . . . . . . . . . . . . . . 1 Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Replacing Shifter Cable Assembly . . . . . . . . . . . . . . . 9 Safety Decals . . . . . . . . . . . . . . . . . . .

WARNING CALIFORNIA PROPOSITION 65 WARNING Engine exhaust and some of its constituents are known in the state of California to cause cancer, birth defects, and other reproductive harm.

SAFETY INFORMATION Introduction SAFE DRESS: Do not wear loose clothing, rings, wristwatches, etc. near machinery. This Safety Alert Symbol is used to call attention to items or operations which may be dangerous to those operating or working with this equipment. The symbol can be found throughout this manual and on the unit. Please read these warnings and cautions, along with all decals, carefully before attempting to operate the unit.

GPR65 & GPR68 RUN IDLE STOP THROTTLE 15843 FORWARD #15843 Diesel only REVERSE 14665 #14465 #13484 #12500 01064 #15874 (not included in kit) OR 16993 16994 #16993 (not included in kit) 1. 2. 3. 4. 5. 6. 7. 8. GASOLINE PLATE OPERATING INSTRUCTIONS Check engine oil level. Open fuel valve. Choke engine. A warm engine may not need to be choked. Open throttle part way. Pull starter rope. After starting: open choke, return throttle to idle position.

GPR77 CAUTION 17287 RUN Machine may fall and cause injury or damage if lifted improperly. Lift by rollcage only. GPR65/68: GPR77: Gas = 330 lbs (149 kg) Gas = 397 lbs (180 kg) Diesel = 360 lbs (163 kg) Diesel = 399 lbs (181 kg) IDLE STOP THROTTLE 15843 #15843 Diesel #17449 Gasoline #17287 FORWARD #12500 WARNING REVERSE 14665 #14665 ROTATING PARTS can crush and cut.

SPECIFICATIONS GPR65 Centrifugal Force GPR68 6000 lbf (27 kN) Exciter vpm GPR77 7775 lbf (34 kN) 4400 vpm 4700 vpm Width & Length 15 in x 26.3 in (381mm x 668mm) 18 in x 26.3 in (457 mm x 668 mm) 22 in x 26.3 in (559 mm x 668 mm) Travel Speed 92 ft./min. (28 m/min.) 88 ft./min. (27 m/min.) 86 ft./min. (26 m/min.) Compaction Depth Up to 22 in (56 cm) See Note Below Compaction Area 6900 sq. ft./hr (640 sq. m/hr) 7920 sq. ft./hr (736 sq. m/hr) 9460 sq. ft./hr (879 sq.

OPERATION Introduction 7. Allow engine to warm up for one or two minutes. Diesel Engine- MBW equipment is intended for use in very severe applications. They are powered by four cycle engines and are available in different sizes and a selection of engines. This parts manual contains only standard parts. Variations of these parts as well as other special parts are not included. Contact your local MBW distributor for assistance in identifying parts not included in this manual. 1.

MAINTENANCE WARNING CAUTION Always exercise the stopping procedure before servicing or lubricating the unit. Always verify fluid levels and check for leaks after changing fluids. After servicing the unit, replace and fasten all guards, shields, and covers to their original positions before resuming operation. Collect and dispose of all hazardous materials according to local legislation. Do not drain oil onto ground, into open streams, or down sewage drains.

3. Remove the (4) 1/2” hex head cap screws securing the engine deck to the baseplate. 13. Assemble the engine deck and handle assembly to baseplate. (Do not tighten bolts) 4. Remove the (4) 1/4” hex head cap screws securing the beltgaurd to the side plate on the engine deck and remove the beltgaurd and belt. 14. Reconnect the shifter/shifter cable assembly to the handle assembly. 5. Now is a good time to inspect and consider replacing the v-belt. 6.

10. If the cable has been properly adjusted, and no resistance is noticed, Skip to step 20. 18. Tighten the 10mm hex bolt (item #10) on the shifter housing until resistance against the shifter lever (item#8) is noticed then loosen slightly. 11. Loosen the 10mm jam nut (item #9) on the shifter housing. 19. Tighten the 10mm jam nut (item #9). 12. Loosen the 10mm hex bolt (item #10) on the shifter housing approximately 1/4”. 20. Repeat steps 6-9.

SERVICE Replacing Shifter Cable Assembly Assembly and disassembly should be performed by a service technician who has been factory trained on MBW equipment. The unit should be clean and free of debris. Pressure washing before disassembly is recommended. Refer to Figure 1 Shifter Cable, page 7. 1. Unbolt and remove the ball joint (item #5). • Prior to assembly, wash all parts in a suitable cleaner or solvent. 2.

2. Remove the (4) 3/8” flanged capscrews securing the rollcage to the engine deck and remove the rollcage. 3. Remove the pulley (item #26) and key (item #4 or #28). 3. Remove throttle cable from engine. Be careful not to loose throttle cable clamp. 4. 4. Remove the (4) 1/4” hex head capscrews securing the beltguard to the side plate on the engine deck and remove the beltguard and belt.

19. Use a 1/4” pin punch at least 2” long through the access holes to press the bearings shafts out of the housing. Shifter Disassembly Refer to Shifter Assembly, page 18. CAUTION Alternate between the two access holes evenly to prevent damage to the housing and bearings during removal. Have an assistant hold the bearings during removal to prevent dropping them. 20. Remove the oil seal (item #7) from the exciter cover. 1. Slide the shaft (item #4) out of the shifting yoke (item #1). 2.

Exciter Assembly 16. Support the shafts by the weights and press on the inner races of the cylindrical bearings (item #6). Refer to Actuator Assembly, page 16. 17. Install two small retaining rings (item #9). 1. Press the cylindrical bearings (item #6) into the exciter housing (item #11). 2. Install two large retaining rings (item #1) into the housing. 3. Press the spherical bearings (item #8) onto the shafts. 19. Align the timing marks on the gears and hold all shafts vertical. 20.

Parts Replacement Cycles and Tolerances Bearings Replace anytime a bearing is rough, binding, discolored or removed from housing or shaft. Clutch Replace clutch if it does not disengage below 1800 rpm. Engine Components Refer to your engine manufacturer’s Owner’s Manual. Hardware Replace any worn or damaged hardware as needed. Replacement hardware should be grade 5 and zinc plated unless otherwise specified. Safety Decals Replace if they become damaged or illegible.

This page intentionally left blank

REPLACEMENT PARTS The warranty is stated in this book on page 28. Failure to return the Warranty Registration Card renders the warranty null and void. DECAL LOCATION MBW has established a network of reputable distributors/ dealers with trained mechanics and full facilities for maintenance and rebuilding, and to carry an adequate parts stock in all areas of the country. Their sales engineers are available for professional consultation.

13 12 7 10 3 6 5 1 4 2 11 9 8 Actuator Assembly - 16 -

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. PART NO. 06858 14391 14392 14393 14406 14407 14408 15131 14432 F0203SP F0208CP F0813SCN F08SW DESCRIPTION KEY, 3/16” SQUARE x 5/8” LONG BELLEVILLE WASHER O-RING, 1.36 ID O-RING, 2.

1 4 2 5 3 Shifter Assembly - 18 -

ITEM PART NO. DESCRIPTION QTY 1. 2. 3. 4. 5.

30 Exciter Assembly - 20 - 35 22 31 5 21 9 6 11 31 1 13 16 9 5 6 10 19 1 10 18 15 17 20 4 10 14 1 10 8 25 14 9 1 24 8 9 34 33 36 35 29 12 2 30 3 7 27 31 26 28 4 23 32

ITEM PART NO. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 01000 01072 01191 06335 07203 07456 07457 07458 07469 08799 14067 14068 14395 14399 19114 14403 14404 14405 14411 14416 19110 14417 19112 14424 14430 14993 15060 17024 19109 17025 19118 19132 17083 19115 19135 F0205SP F051804HCS F051806FWS F051808FSS F051808FWS F051810FWS F05BFW F0618SPP 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. DESCRIPTION GPR65/68 GPR77H GPR77D RETAINING RING, INT.

29 13 3 12 4 18 26 2 8 7 23 16 1 27 17 10 26 25 24 11 6 36 28 35 33 19 20 5 21 22 31 15 32 14 36 9 34 30 Honda Main Assembly - 22 -

ITEM 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. PART NO.

28 9 13 24 25 30 14 29 6 26 7 1 19 16 5 3 10 17 38 2 8 18 27 20 37 36 34 21 23 4 22 32 15 33 12 35 36 11 31 Diesel Main Assembly - 24 -

ITEM PART NO. 1. 2. 00808 01182 05831 06747 F072010FSS 14429 16523 16544 16578 16852 19105 16859 19119 16862 16849 16992 19101 17006 19108 17064 19129 17065 19127 17117 18087 18094 19124 18110 19136 F042006FWS F042006HCS F0420HN F0428HN F051808HCS F05LW F05SW F061608FWS F0616FN F06LW F06SW F071420FSS F0714HN F07LW F081307HCS F0813HN F08LW F08SW M10C016FWS M08C016FWS 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38.

5 3 15 4 1 17 19 2 8 17 19 11 18 Handle Assembly - 26 - 12 10 6 9 14 7 13 16

ITEM PART NO. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 01018 01019 01056 01145 05477 06921 16860 16908 19268 18089 02715 F023204FSS F0232HN F02LW F042007SCS F0420FN F081306HCS F081310HCS F08LW GPR65/68 DESCRIPTION GPR77 GASOLINE GASOLINE BUSHING, NYLON, OUTER BUSHING, NYLON, INNER HAIRPIN, 1/8” x 2-3/8” LG. SPRING CLAMP SWIVEL, THROTTLE CABLE HANDLE BRACKET HANDLE, COATED SHOCKMOUNT, 2” O.D. x 2-1/8 LG.

WARRANTY WHAT DOES THIS WARRANTY COVER? MBW, Incorporated (MBW) warrants each New Machine against defects in material and workmanship for a period of twelve (12) months. "New Machine" means a machine shipped directly from MBW or authorized MBW dealer to the end user. This warranty commences on the first day the machine is sold, assigned to a rental fleet, or otherwise put to first use. MBW warrants each Demonstration Machine against defects in material and workmanship for a period of six (6) months.

NOTES: 29

NOTES: 30