Operating instructions

Table Of Contents

- Front page

- Overview of your AX balance

- Overview of your MX/UMX balance

- Contents

- 1 Getting to know your balance

- 2 Setting up the balance

- 3 Your first weighing

- 4 Basic operating concepts for the terminal and software

- 5 System settings

- 5.1 Calling up the system settings

- 5.2 Overview of the system settings

- 5.3 Settings for adjustment and test

- 5.3.1 Displaying the adjustment history (“History ”)

- 5.3.2 Defining adjustment and test reports

- 5.3.3 “ProFACT ” fully automatic adjustment function

- 5.3.4 Defining an external adjustment weight

- 5.3.5 Defining an external test weight

- 5.3.6 Entering the weight certificate designation

- 5.3.7 Defining the weight identification

- 5.4 Specifiying the weighing parameters

- 5.5 “SmartSens ” settings

- 5.6 Renaming the user profile

- 5.7 Selecting the door function

- 5.8 Selecting peripheral devices

- 5.9 Terminal settings

- 5.10 Resetting to the factory settings

- 5.11 Date and time

- 5.12 Selecting the dialog language

- 5.13 Security settings

- 5.14 Energy-saving function and battery change date

- 5.15 Recording the system settings

- 6 The “Weighing ” Application

- 6.1 Selecting the application

- 6.2 Settings for the “Weighing ” application

- 6.2.1 Overview

- 6.2.2 Select function keys

- 6.2.3 “SmartTrac ” and stopwatch

- 6.2.4 Selecting information fields

- 6.2.5 Manual/automatic transfer of weight values

- 6.2.6 Selecting weighing units

- 6.2.7 Defining custom weighing units

- 6.2.8 Defining the weighing record

- 6.2.9 Parameters for manual record printing

- 6.2.10 Defining identifications and record titles

- 6.2.11 Parameters for processing bar code data

- 6.3 Working with the “Weighing ” application

- 6.3.1 Manually entering the tare preset

- 6.3.2 Changing the resolution of the weighing result

- 6.3.3 Specifying the target weight and tolerances

- 6.3.4 The “SmartTrac ” graphical weighing-in aid

- 6.3.5 Weighing-in and using the statistics

- 6.3.6 Working with identifications

- 6.4 Adjusting the balance and checking the adjustment

- 6.4.1 Fully automatic adjustment using ProFACT

- 6.4.2 Adjustment using the internal weight

- 6.4.3 Adjustment using an external weight

- 6.4.4 Checking the adjustment with the internal weight

- 6.4.5 Checking the adjustment with an external weight

- 6.4.6 Adjustment and test records (examples)

- 7 The "Percent Weighing"Application

- 7.1 Introducing the "Percent Weighing"application

- 7.2 Selecting the application

- 7.3 Settings for the "Percent Weighing"application

- 7.3.1 Overview

- 7.3.2 Special function keys for percent weighing

- 7.3.3 Special information fields for percent weighing

- 7.3.4 Additional unit for percent weighing

- 7.3.5 Special record information for percent weighing

- 7.4 Working with the “Percent Weighing ” application

- 8 The “Density ” Application

- 8.1 Introducing the “Density ” application

- 8.2 Selecting the application

- 8.3 Settings for the “Density ” application

- 8.3.1 Overview

- 8.3.2 Selecting the method for density determination

- 8.3.3 Selecting the auxiliary liquid

- 8.3.4 Special function keys for density determination

- 8.3.5 Special information fields for density determination

- 8.3.6 Special record information for density determination

- 8.3.7 Use of bar codes during density determination

- 8.3.8 Specifying the number of decimal places for the result

- 8.4 Working with the “Density ” Application

- 8.4.1 Determining the density of non-porous solids

- 8.4.2 Determining the density of liquids using a sinker

- 8.4.3 Determining the density of pasty substances using a gamma sphere

- 8.4.4 Determining the density of liquids using a pycnometer

- 8.4.5 Determining the density of porous solids

- 8.5 Additional functions of the “Density ” application

- 8.5.1 Sample identification

- 8.5.2 Printing out the result of a density determination

- 8.5.3 Using the density statistics

- 9 The “Minimum Weighing ” Application

- 9.1 Introducing the “Minimum Weighing ” Application

- 9.2 Selecting the application

- 9.3 Settings for the “Minimum Weighing ” application

- 9.3.1 Overview

- 9.3.2 Special function keys for minimum weighing

- 9.3.3 Special information fields for minimum weighing

- 9.3.4 Information menu for minimum weighing

- 9.3.5 Special record information for minimum weighing

- 9.4 Working with the “Minimum Weighing ” Application

- 10 Loading Applications via the Internet

- 11 Further important information

- 12 Technical data and accessories

- 13 Appendix

- 14 Index

Chapter 8: The "Density" Application

66

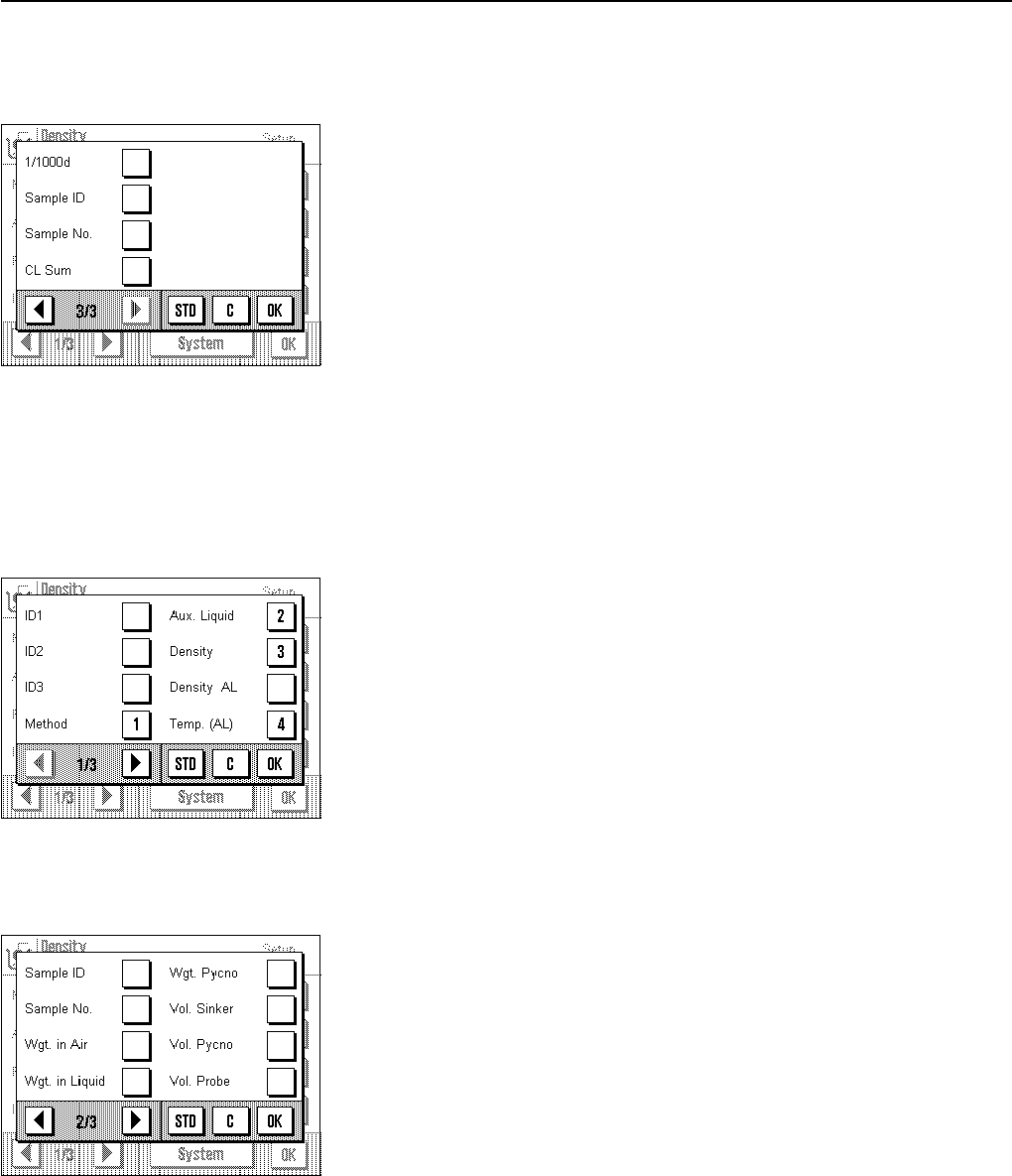

On the last page of the menu there are the following function keys for density

determination:

“Sample ID”: You can use this function key to assign an identification to each

sample whose density you determine, so you can identify it

unambiguously when the results are displayed.

“Sample No.”: You can use this function key to assign a number to each sample

whose density you determine. This makes it easier to identify the

individual samples of a sequence.

“CL Sum”: You can use this function key to delete the results of a series of

density determinations you have stored (statistics) so you can

start a new series of measurements.

All other function keys are the same as for the “Weighing” application.

Factory setting: The “Start”, “Temp. (AL)” and “Result” function keys are

activated.

8.3.5 Special information fields for density determination

In the information fields menu you have additional settings for density determination.

On the first page of the menu you can choose from several information fields for density

determination which provide the following information:

“Method”: Method selected for density determination.

“Aux. Liquid”: Selected auxiliary liquid (for density determination of solids).

“Density”: Result of the last density determination.

“Density AL”: Density of the auxiliary liquid. For water or ethanol the density

displayed is read automatically from the internal density table; for

other auxiliary liquids the density value entered using the function

key with the same name is displayed.

“Temp. (AL)”: Temperature of the auxiliary liquid (distilled water, ethanol). The

temperature displayed is the value entered using the function key

with the same name.

On the second page of the menu there are the following additional information fields for

density determination:

“Sample ID”: Identification of the current sample.

“Sample No.”: Number of the current sample.

“Wgt. in Air”: Weight of the sample in air (for density determination of solids).

“Wgt. in Liquid”: Weight of the sample in the auxiliary liquid (for density determi-

nation of solids).

“Weight Pycno.”: Weight of the pycnometer (for density determination of liquids

using a pycnometer).

“Vol. Sinker”: Volume of the sinker (for density determination of liquids using a sinker).

“Vol. Pycno.”: Volume of the pycnometer (for density determination of liquids

using a pycnometer).

“Vol. Probe”: Volume of the current sample (calculated by the software).

All other information fields are the same as for the “Weighing” application (Section 6.2.4).

Factory setting: The “Method”, “Auxiliary liquid”, “Density” and “Temp. (AL)”

fields are activated.