Technical data

Table Of Contents

- User Instructions for the Micromat boiler

- Product Description

- Technical Data

- Delivery Consignment / Unpacking the boiler

- Boiler location

- Installation Clearances

- Wall Mounting

- Gas Connection

- Gas Conversion

- System Flow & Return connections

- Condensate Connection

- Flue / Combustion Air connection

- Flue Systems

- Calculating Flue Resistance

- Ventilation requirements single appliances

- Hydraulic System Design

- System type 1

- System type 2

- System type 3

- System type 4

- System type 5

- System type 6

- System type 7

- System type 8

- Water Treatment

- Soldering Flux

- Electrical Connection

- System Type 1

- System Type 2

- System Type 3

- System Type 4

- System Type 5

- System Type 6

- System Type 7

- System Type 8

- Commissioning The Micromat EC

- Installation Codes

- First Firing

- Pop Up Menu

- Setting DHW Temperature

- Servicing

- Screen Display Diagnosis of Faults

24

• The MICROMAT EC boiler can be operated to serve a heating load in a number of ways:

I.Constant flow temperature, with the option to set either high temperature (85°C), medium temperature

(75°C) or low temperature (55°C).

2.Direct-on-boiler weather compensated flow temperatures, with adjustable maximum flow temperature.

3.Underfloor heating coils via a VT mixing valve with a maximum flow temperature of 55°C plus a second

circuit (eg. radiators) operating with direct-on-boiler weather compensated temperatures.

• Flow to return drop (∆t). The microprocessor controls monitor return temperature and the facility to dictate a set ∆t

(by pump speed modulation) is a standard and most important feature and will maintain the ∆t across the boiler at

20°C, as the lower the return temperature, the higher the operating efficiency. HT and MT systems should be designed

for ∆t 20°C and LT (underfloor coils via a mixing valve) systems ∆t 10°C. Designing for a ∆t 20°C gives the added

cost saving advantage of smaller pipe sizes and pumps.

• The MICROMAT EC includes ‘in built’ primary pumps with a residual head pressure as listed below.

• Appliances may be installed as single units or in multiples.

• Single units may or may not require additional system pumps which will be dictated by the system configuration

and by the index resistance.

• Multiple units (and single units which require additional pumps), should always be installed with a low loss mixing

header or similar arrangement – see table below.

• The MICROMAT EC boiler has in built domestic hot water (remote stored) temperature control ability, and if re-

quired, the in built pumps may be used to provide the primary flow to a nearby indirect cylinder or calorifier with the

boiler controlling a diverter valve in the main flow or return pipework.

The following system schematics show a number of typical installation types to which the MICROMAT EC boiler may

be connected.

The MICROMAT EC is not limited to just the systems shown, and may be used in conjunction with many

commercially available control items.

For further advice or guidance on schematic designs or control options contact RVR Ltd.

16.0 hydraulic system

design

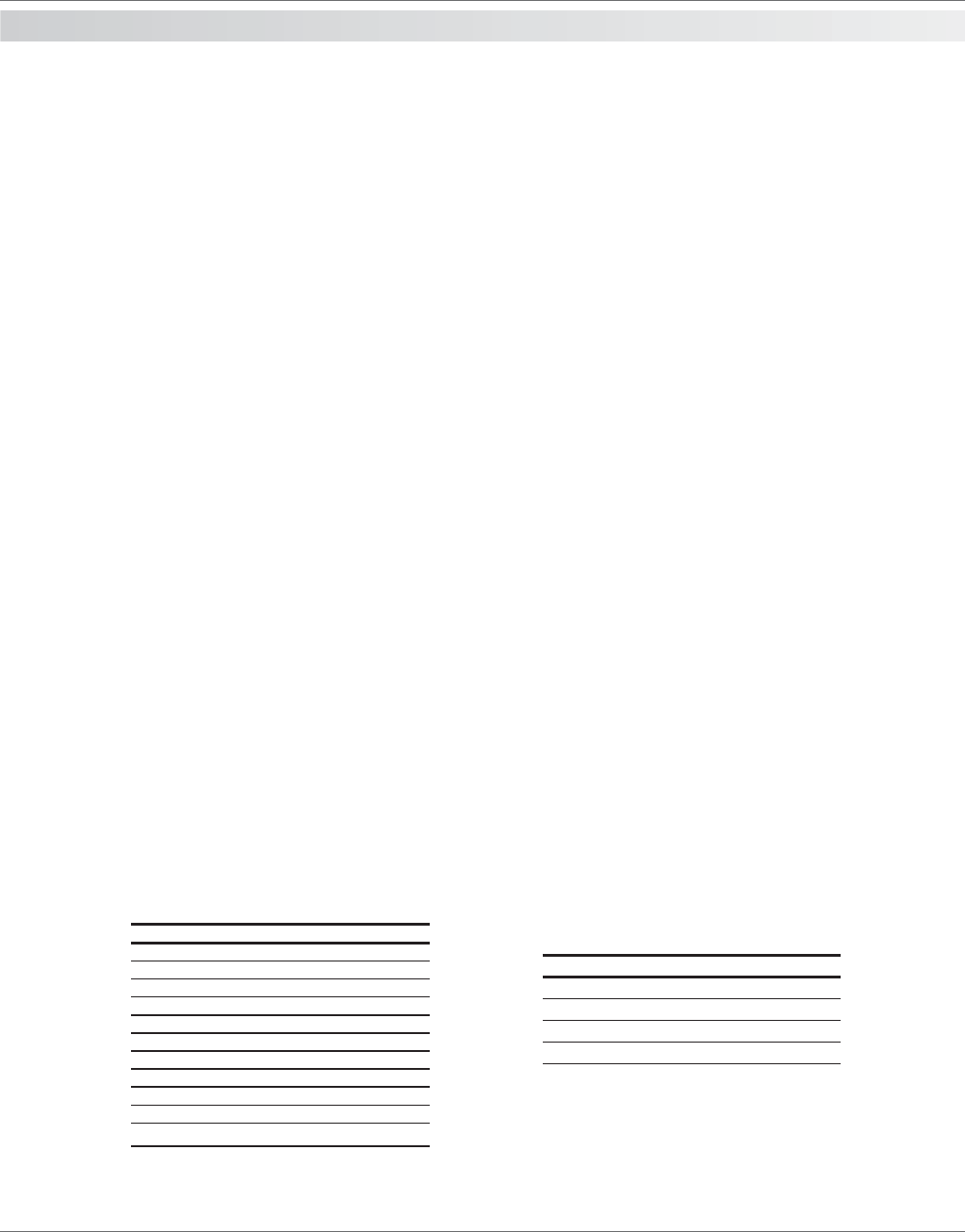

WkrewoPrelioBngiseD ∆ C°02t

54otpUmm04

57mm05

001mm56

021mm56

051mm08

002mm08

052mm001

072mm001

003mm001

043mm001

morfdetaluclacdnaepipleetsotrefersretemaiDebuT

4CediuGESBIC

low velocity mixing header

diameter sizing guide

ledoMrelioBcwserteMerusserP

22/611

82/421

63/131

54/831

Inbuilt boiler pumps

approx residual head pressure at

∆∆

∆∆

∆t 20°C