Specifications

Table Of Contents

- TABLE OF CONTENTS

- CAUTION

- Foreword

- For safe operation

- How to Read This Operation Manual

- CHAPTER 1 Before Use

- CHAPTER 2 Basic Operations

- CHAPTER 3 Useful Function

- Changing origin

- Adjusting head gap

- When nozzles missing can not be improved

- Setting the print condition in a set

- Setting the print condition

- Setting media compensation

- Setting the print method

- Registering head gap value

- Set the scan width of the head

- Changing the UV illumination intensity

- Sets UV irradiation at starting/ ending of drawing

- Setting the priority

- Sets the cooling time per scan

- Initializing the settings

- Turning OFF the UV lamp

- Setting the UV lamp OFF duration

- Changing the UV illumination intensity

- MACHINE SETUP

- Other useful functions

- CHAPTER 4 How to care

- Maintaining

- Ink cartridge

- Washing cartridge

- Cleaning the flushing box

- Avoiding ink dripping at printing

- When the waste ink tray is full

- Setting nozzle face cleaning time

- Perform cleaning automatically when the power supply is turned on

- Preventing nozzle dropout while power-off

- Regular maintenance of white ink

- If blur or missing remains

- Wiper cleaning

- Refill antifreeze liquid

- Cleaning of the UV lamp filter

- Cleaning of the UV power supply filter

- Cleaning of the optional vacuum unit filter

- Replacing the mist fan filter

- Replacing UV lamp

- Checking method of UV illumination intensity

- Cleaning of the Ionizer

- Prevent the nozzle clogging of spot color

- CHAPTER 5 In Case of Trouble

- CHAPTER 6 Appendix

Check first when a trouble occurred

5-3

5

In Case of Trouble

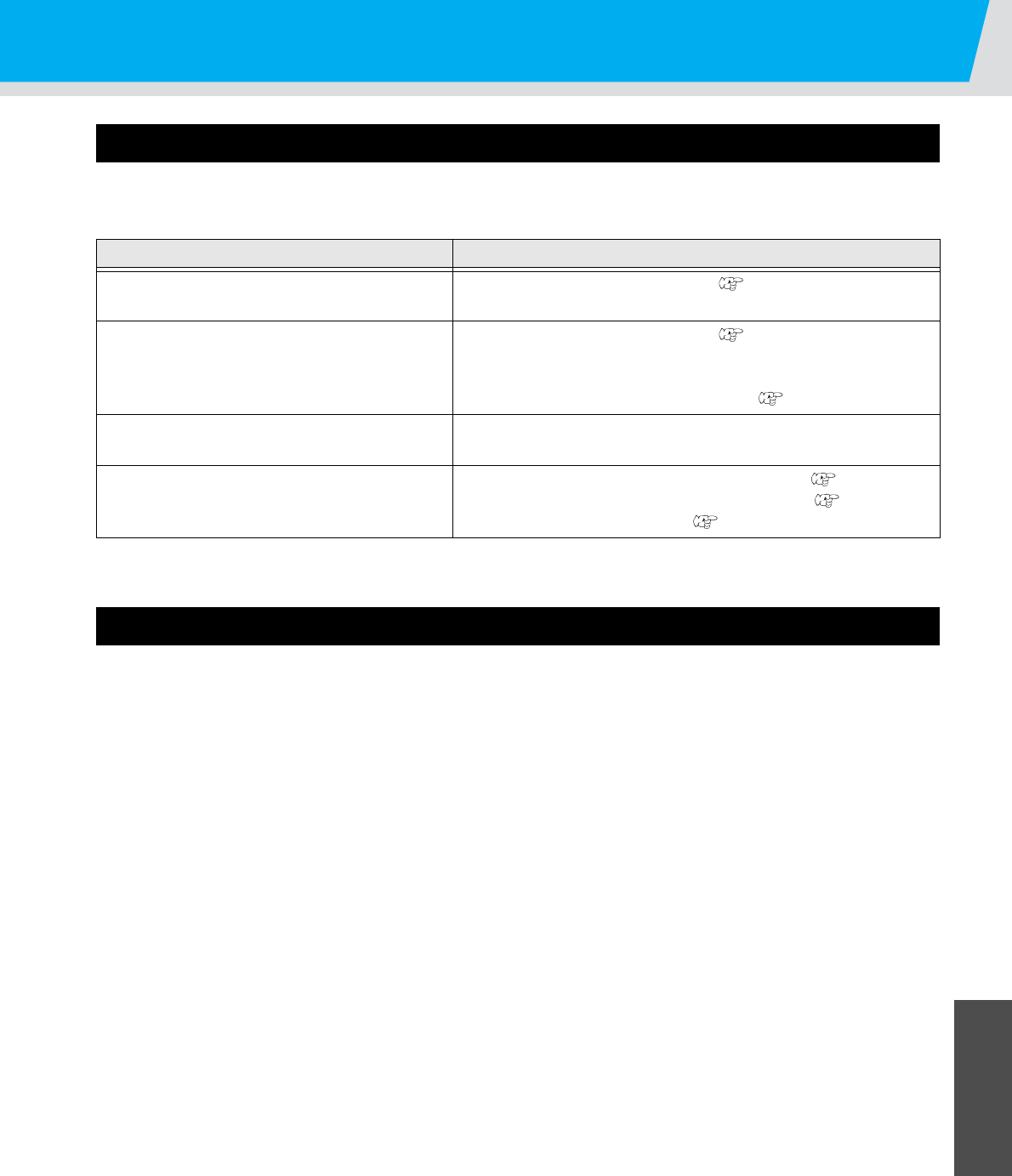

Problems of drawing result

If the drawing result has a problem, follow the table below. If the problem does not improve after that, con-

tact a distributor in your district or our office.

Nozzle clogging

If nozzle clogging is not solved after the head cleaning of P.2-14, check the following 3 items.

Execute cleaning by hard with the operation of P.2-15.

Execute subtank maintenance with the operation of P.4-24.

Replace ink with the operation of P.4-4.

Problem Solution

Lines / blur (1) Execute the head cleaning. ( P.2-14)

(2)If there is slips of paper in the head path, remove them.

Large ink droplet on media (1) Execute the head cleaning. ( P.2-14)

(2)Remove the dust of the media.

(3)Clean dust on the platen.

(4)Clean the bottom of the carriage. ( P.4-10)

Media is raised during drawing and the

drawing stops.

(1)Set new media and start printing.

Ink cannot harden. (1) Check that the head gap is not too wide. P.3-16

(2)Check the UV lamp illumination intensity. P.4-40

(3)

Check the UV light intensity. P.3-19