Technical Specifications

179

Truss & Rafter

© 2015 MiTek. All rights reserved.

MUGT15 Girder Tiedown

Designed for higher uplift resistance for concrete block construction.

The MUGT15 can accommodate variable truss bearing depths.

Materials: 12 gauge

Finish: G90 galvanizing

Codes: See page 11 for Code Reference Chart

Installation:

• Use all specied fasteners. See Product Notes, page 17.

• When straps are wrapped over the truss, install nails in backside

of truss. See MUGT15 installation diagram for minimum nail

requirements into the face and on top of the truss.

• If installed straight-up with no wrap over the top of the truss,

ll all nail holes.

• Moisture barrier may be required.

Typical MUGT15

installation

MUGT15

Ref. No. Qty Dia. Top Face Back Type

160%

Face-Max 1 5/8 -- -- 28 -- -- 10d 4495

Top-Min 1 5/8 4 6 12 10d 4175

1) Allowable loads have been increased 60% for wind or seismic loads; no further increase shall be permitted.

2) Additional anchorage products to be designed by others.

3) Designer must specify anchor bolt type, length, and holdown device.

4)

NAILS:

10d nails are 0.148" dia. x 3" long.

New products or updated product information are designated in

blue font

.

Mounting

Condition

USP

Stock No.

Steel

Gauge

Qty

8, F4,

R10

MUGT15 MGT 12

DF/SP

Allowable Uplift

Loads (Lbs.)

1

Fastener Schedule

2,3,4

Anchor

Rafter/Truss

3

Code

Ref.

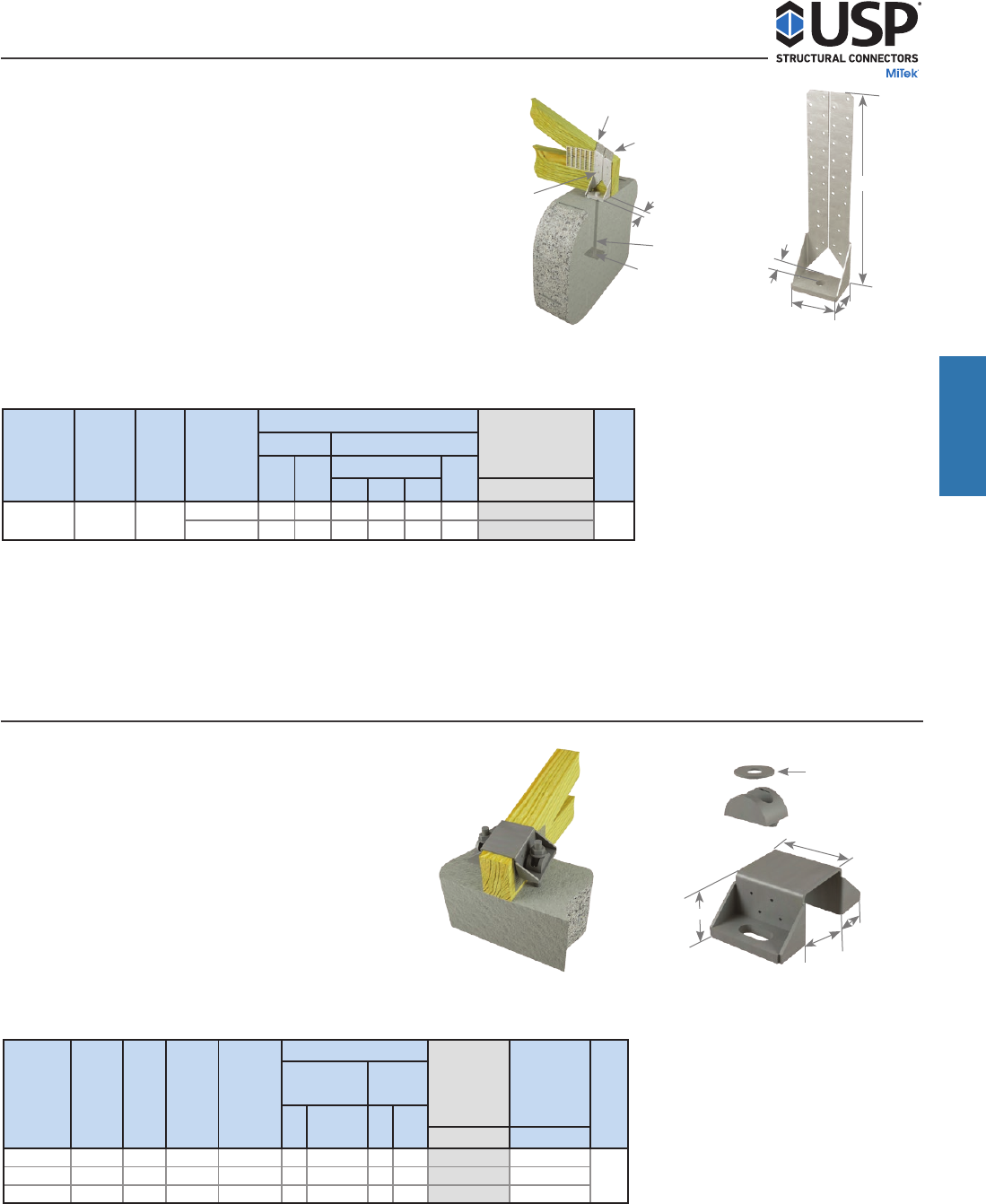

HUGT

Typical HUGT2

installation

The HUGT series high uplift girder tiedowns can be installed on

beams and top chords of trusses with slopes from 0˚ to 34˚.

Materials: 7 gauge

Finish: USP primer

Codes: See page 11 for Code Reference Chart

Installation:

• Use all specied fasteners. See Product Notes, page 17.

• Install the HUGT over the beam or truss (see “W” dimension

on chart for appropriate width).

• Attached members shall be designed to resist applied loads.

• Moisture barrier may be required.

Ref. No. Qty Qty Type

160% 160%

HUGT2 HGT-2 7 3-5/16 5-3/4 2 3/4 8 10d 9790 7020

HUGT3 HGT-3 7 4-15/16 7-3/8 2 3/4 8 10d 9860 9650

HUGT4 HGT-4 7 6-7/8 9 2 3/4 8 10d 9860 9860

1) Allowable loads have been increased 60% for wind or seismic loads; no further increase shall be permitted.

2) Listed loads apply where roof pitch is between 3:12 and 8:12.

3) Additional anchorage products to be designed by others.

4) Minimum nail penetration shall be 1-1/2" for 10d nails.

5) Designer must specify anchor bolt type, length, and embedment.

6)

NAILS:

10d nails are 0.148" dia. x 3" long.

USP

Stock No.

Steel

Gauge

Threaded

Rod

W

(in)

O.C. Dim

Between

Anchors

(in)

Fastener Schedule

3,6

Bolt

Dia.

Code

Ref.

F26

DF/SP

Allowable

Uplift Loads

(Lbs.)

1,2

S-P-F

Allowable

Uplift Loads

(Lbs.)

1,2

Girder

4

HUGT Girder Tiedowns

(2) 3/4" washers are

required if 3/4" dia.

bolt is used (washer

not included)

4"

2-3/16"

W

2-7/8"

Truss & Rafter

14-5/8"

1-1/4"

3-11/16"

2-7/16"

Install a minimum of (12)

10d nails into back

Install a minimum of (4)

10d nails into the top

5/8" bolt

1-1/4"

Min. 3" x 3" x 1/4"

bearing plate

Install a minimum of (6)

10d nails into face