Use and Care Manual

280

Copyright © 2020 MiTek Industries, Inc. All Rights Reserved

Plated Truss

Plated Truss

MiTek

®

Product Catalog

SNP Skewed Nail Plate

The SNP3 Skewed Nail Plate is designed for connecting square

cut corner jack trusses at skews from 0° to 90°, as depicted in

Figure 1 below. An alternate installation for front side attachment

at skews 0° to 45° is depicted in Figure 2 below.

Materials: 16 gauge

Finish: G90 galvanizing

Codes: See chart for code references

Installation:

• Bend angle only once.

• 8d common (0.131" dia. x 2-1/2" long) nails may be used in lieu

of 8d (0.131") x 1-1/2" nails with no reduction in load.

Typical Installation (Figure 1):

• Attach the SNP3 to the supported truss on the acute angle

side so the SNP3 runs behind the end of the jack truss. Use all

the specied fasteners listed in the table below. The fasteners

should be installed nearest to bend line as possible then working

to the opposite end of ange. Not all nail holes will be lled.

• Set the jack truss against the supporting truss and nail the

exposed ange of the SNP3 into place. Use all the specied

fasteners listed in the table below. The fasteners should be

installed nearest to bend line as possible then working to the

opposite end of ange. Not all nail holes will be lled.

Alternate Installation (Figure 2):

• Attach the SNP3 to the supported truss on the obtuse angle

side so the SNP3 is on the front side of the jack truss. Use all

the specied fasteners listed in the table below. The fasteners

should be installed nearest to bend line as possible then working

to the opposite end of ange but no closer than 5/8” from the

end of the truss. Not all nail holes will be lled.

• Set the jack truss against the supporting truss and nail the

exposed ange of the SNP3 into place. Use all the specied

fasteners listed in the table below. The fasteners should be

installed nearest to bend line as possible then working to the

opposite end of ange. Not all nail holes will be lled.

Download Download

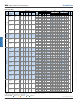

Ref. No. Qty Type Qty Type (100/115/125) (100/115/125)

Figure 1 6 8d x 1-1/2 6 8d x 1-1/2

475 475 415 415

IBC, FL, LA

Figure 2

6 8d x 1-1/2 6 8d x 1-1/2 335 335 295 295 --

1) Allowable loads have been increased 60% for wind or seismic loads; no further increase shall be permitted.

2) Install specified fasteners from the bend line out from each end. Not all nail holes will be filled.

3) When installing SNP3's back to back, the table loads shall be multiplied by a reduction factor of 0.78.

4) Refer to images for installation type.

5)

NAILS:

8d x 1-1/2 nails are 0.131" dia. x 1-1/2" long.

New products or updated product information are designated in

blue font

.

SNP3 TJC37 16

Installation

Type

4

Code

Ref.

Upift

160%

Upift

160%

Fastener Schedule

2

DF/SP

Allowable Loads (Lbs.)

1

S-P-F

Allowable Loads (Lbs.)

1

MiTek USP

Stock No.

Steel

Gauge

Supporting

Member

Supported

Member

Typical SNP3 installation

Figure 1

SNP3

Alternate SNP3 installation

Figure 2

Supporting

truss

3-1/2"

3-1/2"

Supported

truss

0°

to

90°

Supporting

truss

3-1/2"

3-1/2"

Supported

truss

0° to 45°

3-1/2"

3-1/2"

3-3/8"