Specifications

-

101

-

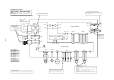

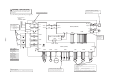

CNM

D

EEV

T2

A

EEV

B

EEV

HEATER

CNC

CNL

C

EEV

Y/G

G2

N_1

P_1

BK

RD

N_1

P_1

DC-N

DC-P

PWB3 (CAPACITOR)

BK

RD

CNG

L

AF_L2

AF_L1

T1

A

UNIT

CNH

CNG

BK

PWB1 (MAIN)

AC.N

AC.L

G3

CNHCNG

CNT CNKCNJCND

CNB

CNO

WH

BK

EARTH

Y/G

Y/G

250V 20A

FUSE

FMo

PWB2 (POWER)

V

CM

W

U

CNI

20S

RD

3

2

1

WH

BK

N

L

BL BL

N-1

L-1

OR

OROR

OR

BK

WH

RD

BK

RD

WH

AC.N

AC.L

GR GR

Y/G

EARTH

EARTH

Y/G

1

2

3

BR

BK

WH

CNP

UNIT

B

T3

T4

C

UNIT

3

2

1

EARTH

WH

BK

BL

Y/G

CNR

EARTH

1

2

3

UNIT

D

T5

Y/G

YL

BK

WH

CNS

1 Phase

220-240V 50Hz

Power Source

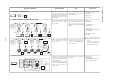

● Inspection of electronic expansion valve

To test if there is voltage.

(Voltage is only applied to the electronic expansion valve when the valve angle is be-

ing changed.)

Red to white

Red to Orange

Brown to yellow

Brown to blue

If the expansion valve does not operate as shown above, it is defective.

Normal if there is approximately DC 5 V 10 seconds

after the power supply is turned on.

}

● Power supply and serial

signal inspection

1 to 2: AC220/230/240V

2 to 3: Normal if the voltage

oscillates between DC 0

and approx. 12V

● Inspection of inductor conductivity

Remove the connector and check for conductivi-

ty. It must be conductive.

● Inspect power

transistor.

Remove the fasten

terminal and test

output voltage.

*

Check fuse. There should be conductivity.

CAUTION – HIGH VOLTAGE

High voltage is produced in the control box. Don’t touch

electrical parts in the control box for 5 minutes after the

unit is stopped.

u * Check these points with the power supply on.

SSCM80ZG-S

Black

Red

White

Yellow/Green

BK

RD

WH

Blue

Yellow

BL

Brown

BR

Gray

GR

Orange

OR

YL

Y/G

Color symbol

LED E

ERROR

Tho-D Tho-CTho-A Tho-R

● Inspection of resistance value of sensor.

Remove the connector and check the resistance value.

See the section of sensor characteristics on page 91.

● Display lamp inspection

• LED E (Abnormality display lamp - Red) ON or flashing: Protection function operating

*