Service manual

11

B-60

463

ENGINE

-

Crankshaft, Flywheel and Drive

Plate

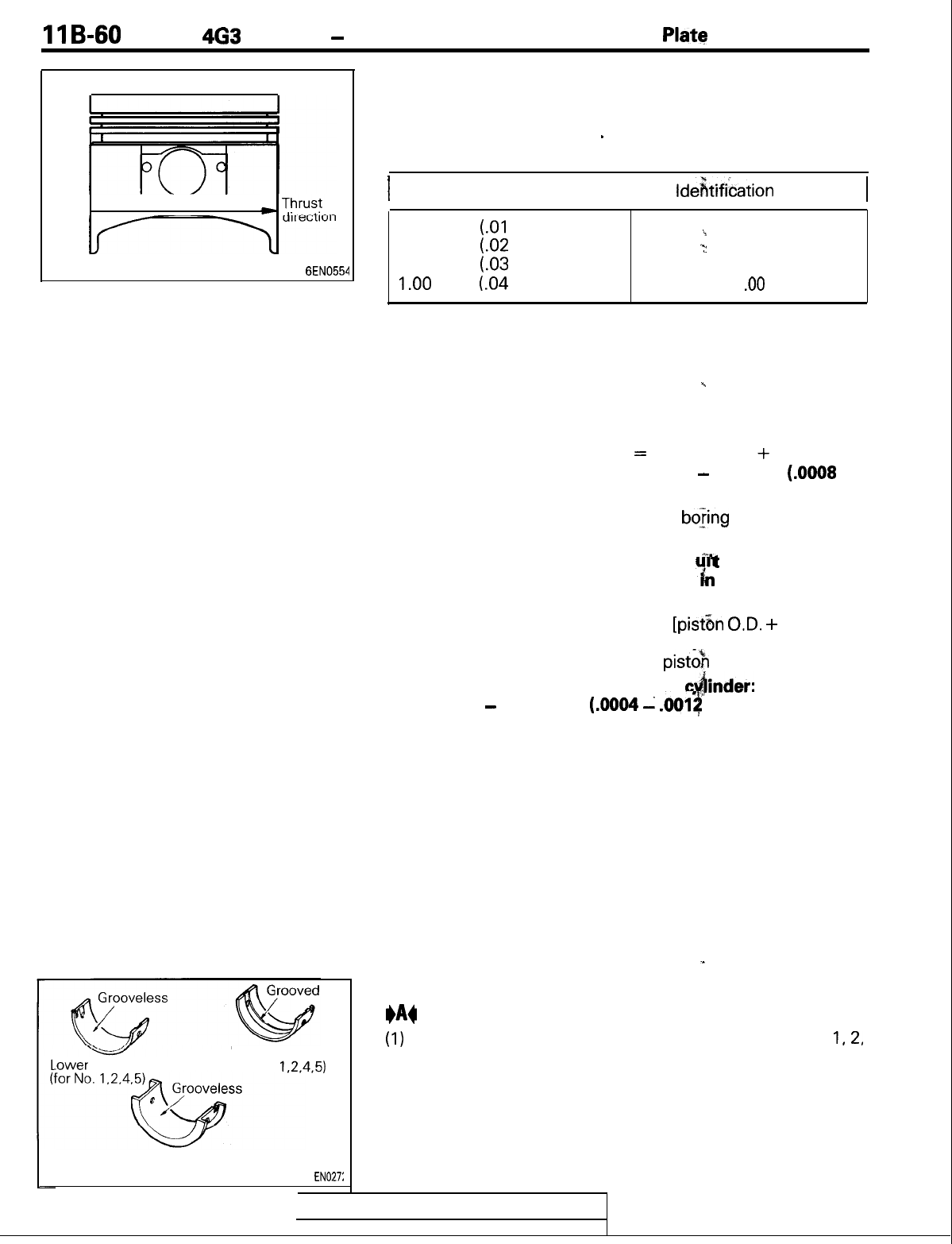

Piston O.D. “A”

6EN0554

.ower bearing

Upper bearing

(for No.

1,2.4,5)

Upper and lower bearings

(for center)

1

EN027:

CYLINDER BORING

(1) Oversize pistons to be used should be determined on the

basis of the largest bore cylinder. .

Piston size identification

’

I

Size

I

Ideitification

mark

1

0.25

mm

(.Ol in.) O.S.

‘.

0.25

0.50

mm

(.02

in.) O.S.

‘”

0.50

0.75

mm

(.03

in.) O.S.

0.75

1.00

mm

(.04

in.)

O.S.

1

.oo

NOTE

Size mark is stamped on the piston top.

(2) Measure outside diameter of piston to be used. Measure it

in thrust direction as shown.

*

(3) Based on the measured piston O.D.; calculate the boring

finish dimension.

Boring finish dimension

=

Piston O.D.

+

(clearance

between piston O.D. and cylinder)

-

0.02 mm

(.OOOS

in.)

(honing margin)

(4) Bore all cylinders to the calculated boiing finish dimension.

Caution

To prevent distortion that may

res

-It

from temperature

rise during honing, bore cylinders,

x1

the order of No. 2,

No. 4, No. 1 and No. 3.

(5) Hone to final finish dimension

[pisGn

0-D.

+

clearance

between piston O.D. and cylinder.],-

(6) Check the clearance between

pisto?r

and cylinder.

Clearance between piston and cdinder:

0.01

-

0.03 mm

(.0004

-

.0012

in.)

NOTE

When boring cylinders, finish all of four cylinders to the same

oversize. Do not bore only one cylinder to an oversize.

INSTALLATION SERVICE POINTS

*A4

CRANKSHAFT BEARING INSTALLATION

(1)

The upper bearings (on the cylinder block side) for Nos. 1,2,

4 and 5 journals are provided with oil groove.

(2) The lower bearings (on the cap side) for Nos. 1, 2, 4 and 5

journals are not provided with oil groove.

(3) The upper and lower bearings for No. 3 journal are common

parts which are flanged and are not provided with oil

groove.

TSB

Revision

I