Service manual

4G3

ENGINE

-

Fuel and Emission Parts

Yrm7

6FU192C

6EM038

3EN015;

0-rinb

6FUO714

INSPECTION

. .

-’

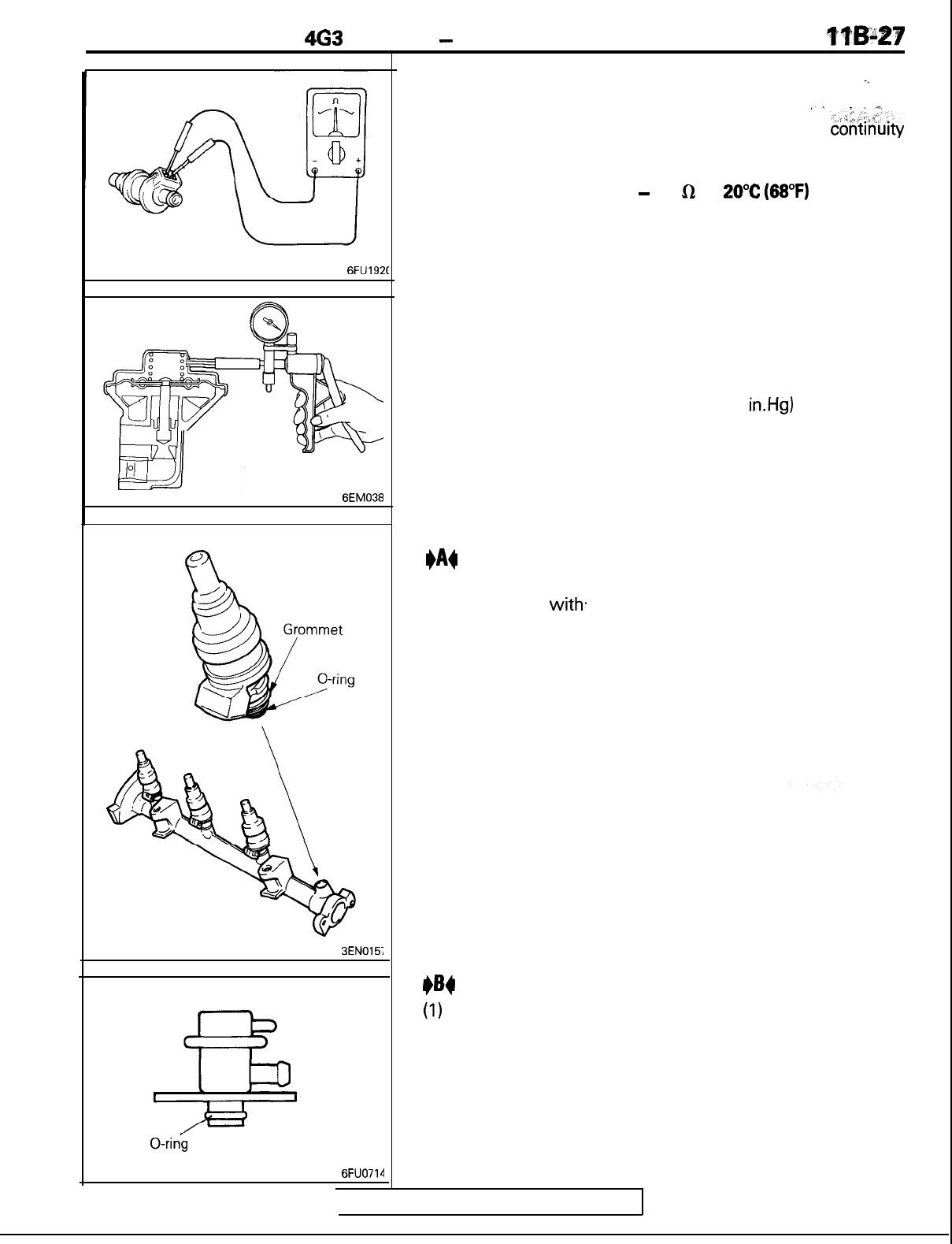

INJECTORS

,.

x,r,

(1) Using an ohmmeter (circuit tester), test for

con&uity

between terminals of injector; the circuit should be closed.

If failure is detected, replace the injector.

Standard value: 13

-

16

n

at

20°C

(68°F)

EGR VALVE

(1) Check EGR valve for sticking or carbon deposits.

If such conditions exist clean or replace EGR valve.

(2) Connect a hand vacuum pump to the nipple of EGR valve

and plug the other nipple.

(3) Apply a vacuum of 500 mm Hg (19.7

in.Hg)

to make sure

that vacuum is maintained. If there is a leak, replace the

EGR valve.

In addition, check the valve for its opening and closing

motion by applying and removing vacuum.

INSTALLATION SERVICE POINTS

I)A4

INJECTOR INSTALLATION

(1) Before installing an injector, the rubber O-ring must be

lubricated with. a drop of clean engine oil to aid in

installation.

(2) Install injector top end into the fuel pipe. Be careful not to

damage O-ring during installation.

r)64 FUEL PRESSURE REGULATOR INSTALLATION

(1)

Before installing the pressure regulator, the O-ring must be

lubricated with a drop of clean engine oil to aid in

installation.

TSB Revision