Specifications

8

the wrinkles disappear, then go over the area again,

pushing down on the iron to bond the covering to the

wood. If the wrinkles don’t disappear, the balsa in

that area might be fl exing inward. If this is happening,

don’t press down. Simply let the heat of the iron shrink

the covering. If the wrinkles momentarily disappear,

then immediately reappear, the iron may be too hot,

thus causing air bubbles. Lower the temperature of

the iron or use a sharp #11 blade to puncture several

holes in the covering, then reheat. The suggested

iron temperature is around 360 degrees F.

The P-47 had many attributes that led to its

reputation. One of the most important was its

durability in combat. Oftentimes the P-47 would

bring pilots home with missing cylinders, blown-off

wing tips and large portions of tail surfaces missing.

The P-47’s internal systems were also durable and

well protected.

MOUNT THE AILERON SERVOS

❏

❏

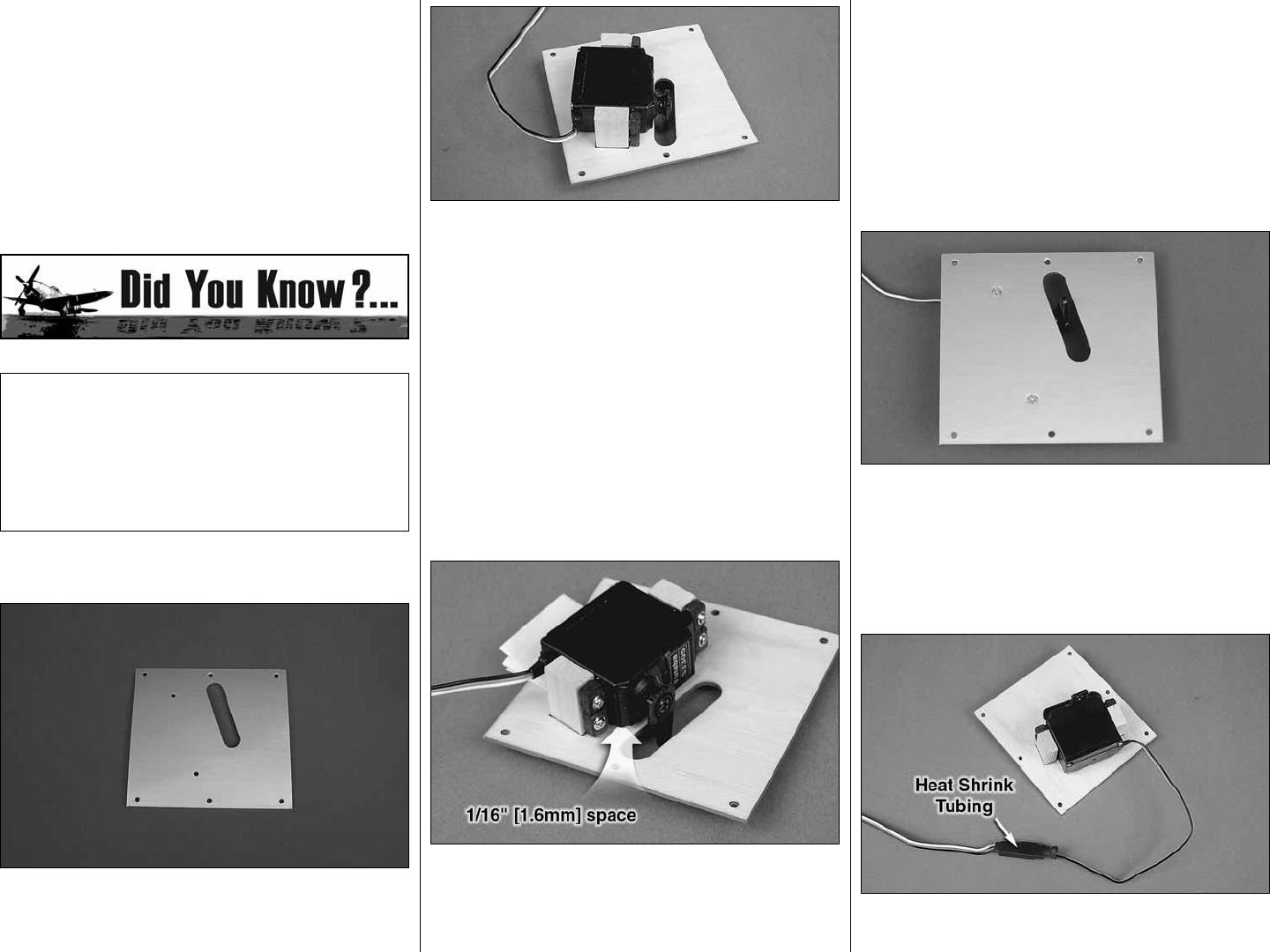

1. Use a sharp hobby knife to trim the opening

from over the left aileron servo hatch and the eight

screw holes.

❏

❏

2. Install a servo arm on the aileron servo.

Position the aileron servo on the aileron servo hatch

cover as shown with the servo arm centered in the

opening. Set the two 5/16" x 5/8" x 13/16" [7.9 x 15.8

x 20.6mm] hardwood blocks in the embossed servo

block locations, checking that they are correct. If not,

mark the new location.

❏

❏

3. Use 6-minute epoxy to glue the two blocks

to the bottom of the servo hatch over the embossed

servo block locations. Thoroughly coat the end of

the blocks and allow them to set for a few seconds

while the blocks absorb the epoxy. Then, recoat the

blocks. Use clamps to hold the blocks to the servo

hatch tray.

❏

❏

4. Once the epoxy has cured, remove the

clamps. Place a 1/16" [1.6mm] spacer, such as a piece

of cardstock or a piece of paper folded several times,

under the servo and between each mounting block.

After the servo is installed the spacer will be removed,

providing adequate spacing for vibration isolation.

❏

❏

5. Drill 1/16" [1.6mm] holes through the blocks

for the servo mounting screws. Mount the servo to

the blocks with the screws that came with the servo.

Remove the servo mounting screws and apply a

couple of drops of thin CA in each hole to harden the

threads. Allow the CA to fully harden. Then, reinstall

the servos and remove the spacer.

❏

❏

6. Drill 1/16" [1.6mm] holes through the blocks

at the two hole locations on the top of the aileron

servo hatch. Install two #2 x 3/8" [9.5mm] fl at head

sheet metal screws to secure the servo mounting

blocks to the aileron servo hatch. Use thin CA to

harden the screw threads

❏

❏

7. Connect a 24" [610mm] servo extension wire

to the aileron servo. Cut a piece of heat shrink tubing