Specification Guide

SST

™

PB3 Remote

Module For PROFIBUS

112016 Remote PLC

Communication Modules

Order No. 987650-5731 Printed in EUR/GF/2011.04 ©2011, Molex

www.molex.com/link/sstpb3remote.html

Product Information

Product Package

Engineering Tools

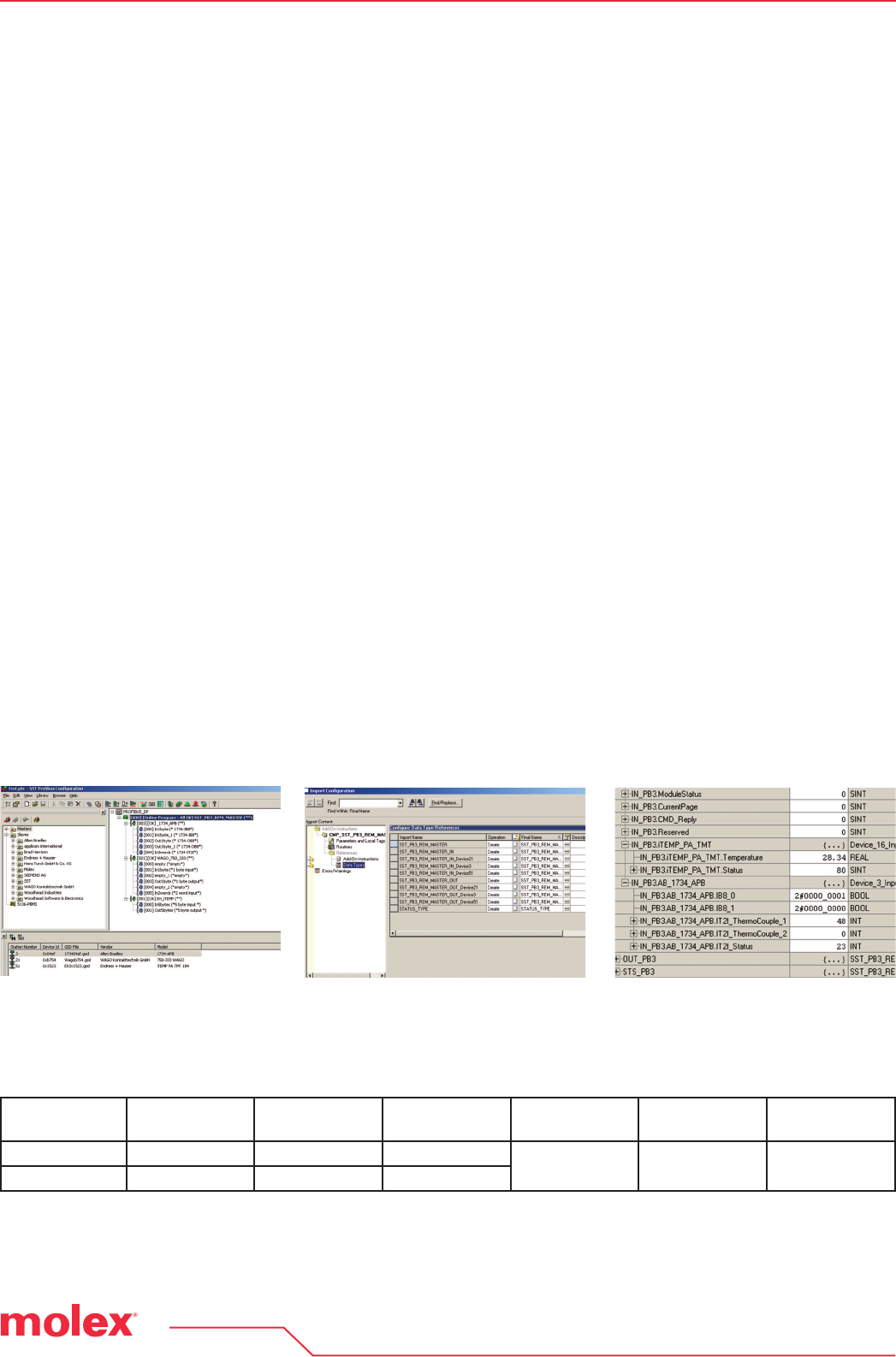

• Profibus Configuration console

- Remote DP slave configuration and

diagnostics

- Automatic DP slave detection

- Automatic naming of I/O process

variable based on GSD file

- Export of I/O process variables in

R

SLogix L5X format

• CommDTM driver for FDT Frame tools

- PROFIBUS Master DP-V1

configuration

- Device diagnostics

- Device detection

Supported OS:

• Windows (32-bit & 64-bit): 7, Vista, 2008

Server, 2003 Server, XP

• VMware 7.0, VMware player 3.1

Technical Data

Memory

• 4 Mb of onboard memory

• 1 Mb of flash memory (user configuration

and firmware upgrade)

Diagnostic LEDs

• 4x Module status

- System Fault

- Profibus State

- Bus Fault

- PLC RUN/PROG

• 3x Ethernet: IP Status, Link

(port 1, port 2)

I/O Size (using 4x CIP Modules)

• Maximum of 1984 input bytes

• Maximum of 1968 output bytes

• 250 words status

Shielded housing

DIN Rail mounted

Compact Dimensions:

18 x 7 x 16 cm / (7 x 2.75 x 6.30 inches)

Conformal coated version

Operating Temperature:

0

°C to +65°C

-25°C to +70°C (Coated version)

Storage Temperature: -40°C to +85°C

Power Supply: 24V

Current Consumption:

850 mA @ 5V or 1.75 mA @ 24V

Communication Ports

1x PROFIBUS port

• Sub-D, 9-pin, female

• PROFIBUS RS485 with galvanic

insulation (500 V)

• 9.6 Kbps to 12 Mbps

2x RJ45 Ethernet port switch

• 10/100 Mbps, auto negotiation

• IP Addressing (via 2 rotary switches):

DCHP (default), DHCP with name

(“SST_PB3_xxx”), Factory Fixed,

Factory Selectable, Flash Saved (via

0xF5/0xF6 EIP objects)

• Manages duplicate IP addressing

Protocols

PROFIBUS

• Master

-

PROFIBUS DP-V0 Class-1 & Class-2

- PROFIBUS DP-V1 Class-1 & Class-2

• Slave

- PROFIBUS DP-V0

• Supports Master, simultaneous

Master&Slave, and Slave only modes

EtherNet/IP

• Explicit Messaging: I/O, DP diagnostic,

D

P Slave parameters, DP slave

enable/disable, DP SetSlaveAddress, DP-

V1 Read/Write, etc

Conformances

• CE, RoHS, UL Listed, IEC 61131-2

• Class 1 / Div 2 - Groups A,B,C & D for

hazardous (Classified) locations

• RINA Marine Certificate

• Rockwell Encompass Global programme

Order No. Engineering No.

Conformal Coated?

(*)

Operating

Temperature Range

Protocol Description MOQ

112016-5000 SST-PB3-REM No 0 to +65°C

PROFIBUS

Remote Module with

DTM driver,

DIN Rail, 24V

1pc

112016-5001 SST-PB3-REM-CC Yes -25 to +70°C

S

PECIFICATIONS

ORDERING INFORMATION

(*): Conformal coating material is applied to electronic circuitry to act as protect against moisture, dust, chemicals, and temperature extremes

PROFIBUS Engineering Console Add-On-Instructions Direct Access in RSLogix

to PROFIBUS Tags