Troubleshooting Guide

Table Of Contents

- Foreword

- Safety Notice

- CONTENTS

- Safety Notice on Maintenance

- Safety Notice on Operation

- 1. Product Introduction

- 2. Control

- 2.1 Operation Mode

- 2.2 Control Mode

- 2.3 Functions

- 2.3.1 Set Capacity Dial Code

- Set the capacity of the outdoor unit through the f

- Capacity

- 24K

- 36K

- 48K

- 60K

- Dial Codes

- 2.3.2 Set Defrost Mode

- The second digit dial code are selecting the defro

- 2.3.3 Set Operating Mode

- The third digit dial code and the fourth digit dia

- By setting the Forcible mode dial codes of the con

- Energy saving mode is achieved by setting the cond

- 2.3.4 Set Indoor Fan Speed

- Set the indoor fan speed through the four-digit di

- Capacity

- 24K indoor unit dial code

- 36K indoor unit dial code

- Level 1 (Default)

- Level 2

- Level 3

- Capacity

- 48K indoor unit dial code

- 60K indoor unit dial code

- Level 1 (Default)

- Level 2

- Level 3

- 2.3.5 Forced Defrost Control

- Press and hold "SW1" for about 5s to enter the fir

- 2.3.6 Refrigerant Recovery Control

- Press and hold "SW1" for about 5s to enter the fir

- 2.3.7 Forced Operation Control

- Press and hold "SW1" for about 5s to enter the fir

- 2.3.8 Thermostat Functions

- Thermostat model: XE70-00/E1, please refer to the

- 3.1 Wiring Diagrams

- 3.2 PCB Layout

- 3.2.2 IPM, PFC Testing Method

- 3.3 Error Code

- 3.4 Troubleshooting

- 3.4.1 “E1” Compressor High Pressure Protection

- 3.4.2 “E3” Compressor Low-pressure Protection, Ref

- 3.4.3 “E4” Compressor Air Discharge High-temperatu

- 3.4.4 “F2” Condenser Temperature Sensor Error

- 3.4.5 “F3” Outdoor Ambient Temperature Sensor Erro

- 3.4.6 “F4” Discharge Temperature Sensor Error

- 3.4.7 “F6” ODU Tube Temperature Sensor Error

- 3.4.8“EE” ODU Memory Chip Error

- 3.4.9 “H4” Overload

- 3.4.10 “H5” IPM Protection

- 3.4.11 “H6” DC Fan Error

- 3.4.12 “H7” Driver Out-of-Step Protection

- 3.4.13 “HC” PFC Protection

- 3.4.14 “Lc” Startup Failure

- 3.4.15 “P0” Driver Reset Protection

- 3.4.16 “P5” Over-Current Protection

- 3.4.17 “P6” Master Control and Driver Communicatio

- 3.4.18 “P7” Driver Module Sensor Error

- 3.4.19 “P8” Driver Module High Temperature Protec

- 3.4.20 “PA” AC Current Protection

- 3.4.21 “Pc” Driver Current Error

- 3.4.22 “PL” Bus Low-Voltage Protection

- 3.4.23 “PH” Bus High-Voltage Protection

- 3.4.24 “PU” Charge Loop Error

- 3.4.25 “ee” Drive Memory Chip Error

- 3.4.26 “e1” High Pressure Sensor Error

- 3.4.27 “C4” ODU Jumper Cap Error

- 3.5 Failures Not Caused by Errors

- 4. Maintenance

- Appendices

- 1. Resistance/Temperature Lists of Temperature Sen

- 2. Temperature/Pressure List of Refrigerant

- 3. Operation Tools

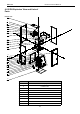

MRCOOL Universal Service Manual

104

8

Inductance

9

Terminal Board

10

Terminal Board

11

Radiator

12

Main Board

13

Condenser Assy

14

Filter Sub-Assy

15

Electromagnetic Valve Sub-Assy

16

Magnet Coil (Electromagnetic Valve)

17

Electromagnetic Valve

18

Strainer

19

Brushless DC Motor

20

Axial Flow Fan

21

Cabinet

22

Diversion Circle

23

Front Grill

24

Front Side Plate

25

Compressor And Fittings

26

Handle

27

Chassis Assy

28

Foot

29

Cut Off Valve

30

Fusible Plug

31

Gas-liquid Separator

32

Accumulator

33

4 Way Valve Coil

34

Drainage Hole Cap

35

Temperature Sensor

36

Temperature Sensor

37

Electrical Heater(Compressor)

38

Electrical Heater (Chassis)

39

Electric Expansion Valve Sub-Assy

40

Drainage Joint

41

Cut-Off Valve 3/8(N)

42

Strainer

43

Electric Expand Valve Fitting

44

One Way Valve

45

Electronic Expansion Valve

46

Strainer

47

Electric Expand Valve Fitting

48

Electric Expansion Valve Sub-Assy

49

Rear Side Plate

50

4-Way Valve Assy

51

Silencer

52

Pressure Protect Switch

53

Filter