Instructions

Table Of Contents

Maintenance and servicing

26

8 Maintenance and servicing

Observe the safety instructions in Ch. Safety, from page 6 on.

Information regarding tightening torques for screws and nuts can be found

in Ch. Technical data, page 11.

Maintenance and servicing of the vibrators may only be performed by reg-

ularly trained, authorised and qualified personnel. Work on the electrical

system may only be carried out by a qualified electrician.

The qualified personnel has to work exclusively with tools suitable for the

application.

In the case of unauthorised intervention in the NEA/NEG there is no longer

any warranty claim.

Before all maintenance and servicing work the NEA/NEG must be safely

disconnected from the electrical mains. The procedure is as follows:

1. Switch off NEA/NEG.

2. Secure against unintentional switching on.

3. Determine that NEA/NEG are voltage free.

4. Earth and short-circuit.

5. Cover and fence off neighbouring live parts.

Interventions in the NEA/NEG, such as lubricating/changing of bear-

ings or opening the terminal box, must not be performed in potentially ex-

plosive atmospheres.

When operating in a potentially explosive dust atmosphere, the opera-

tor must regularly check the condition of the bearings and the duration of

operation of the vibrators. Damaged bearings or bearings whose service

life has been reached, must be replaced immediately. Alternatively, the

vibrators can also be sent to

Netter

Vibration for replacement of the bear-

ings.

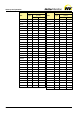

Maintenance of the NEA/NEG must be carried out as follows:

Interval

Action

If required (depend-

ing on operating

conditions)

Clean the NEA/NEG regularly with a wet cloth to remove dust

deposits.

After one hour op-

eration after initial

start-up

Check screw connections and retighten if necessary.

Every 1000 operat-

ing hours

NEA/NEG from housing size 130 up, with speeds > 3000 rpm:

lubricate bearing with grease of the type KLUEBER

Isoflex NBU 15.

Every 5000 operat-

ing hours

NEA/NEG from housing size 130 up, with speeds < 3000 rpm:

replace the grease of the roller bearings completely, with grease

of the type KLUEBER Staburags NBU 8.

Technical data

Expertise and

regulations

Maintenance

plan