Product Manual

24

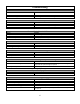

Lid

Insulation

cap

Heating

coil

Heating

chamber

Inspect Heating Coil and Desoot as Needed

Inspect and desoot coil annually. Although most coils

never require desooting, poor grades of fuel oil or

inadequate combustion air will cause heavy soot build-

up on the outside surface of the heating coil tubing.

These deposits will insulate the coil, which then restricts

airflow through the heat exchanger and further

aggravates the soot build-up.

If soot has built up on the exterior of the coil tubing,

clean as follows:

• Wear protective clothing, goggles, and gloves.

• Disconnect high-pressure hose on inlet side of

coil and thermostat on outlet side of coil.

• Remove the lid and insulation cap from the

heating chamber and hoist the coil out. The coil

weighs 125 lbs.

• Clean the coil.

• Reassemble the coil and lids to the machine.

Make sure white insulation remains in place.

Figure 20 – Heating Chamber Interior

• Reattach high-pressure hose and thermostat and

make sure all fittings are tight before using

machine.

Inspect/Clean/Adjust Electrodes

Inspect electrodes annually and make adjustments as

needed.

• Tip machine back until it rests on the frame.

• Remove the 4 nuts that attach burner to the

heating chamber. You do not have to disconnect

the fuel lines or electric cords.

Figure 21

• Let burner fall away from the heat exchanger.

• Clean off carbon deposits, which may have

accumulated on the tips of electrodes.

• Reset the spacing as shown below in Figure 23.

• Reattach burner to the heat exchanger.

4 nuts

Figure 22