Use and Care Manual

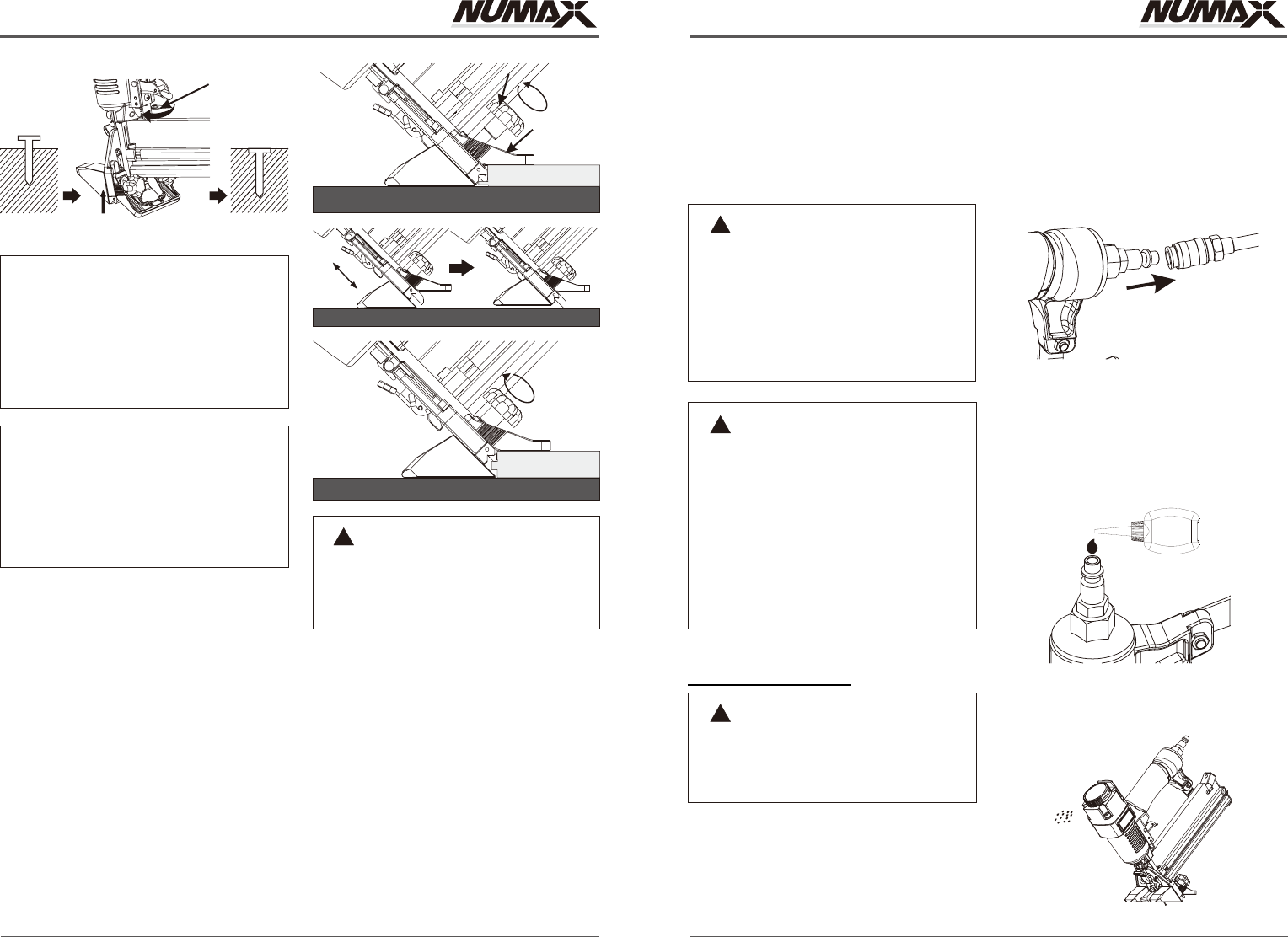

Turn the adjustment knob clockwise

It is advisable to test the depth on a

scrap workpiece to determine the

required depth for the application.

To determine depth of drive, first adjust

the air pressure and drive a test

fastener. Never exceed 110 psi.

CAUTION:

When use the tool as a flooring nailer,

the depth adjustment wheel must be

set at the top of the wheel bar.

To set the wheel:

1.Turn the wheel right to move the

wheel up.

2.Set the wheel at the top of the wheel.

NOTE:

Disconnect the tool from air source.

Loose the plastic screw (K) on both sides of

the flooring plate (L).

Slide the floor plate up or down to suit your

flooring application.

Fasten the plastic screws tightly.

Ensure the correct depth set for the wood

floor by firing into a scrap piece of flooring

and checking for proper fastener

placement.

ADJUSTING THE FLOORING PLATE

When the flooring nose cover set on the nailer,

the floor plate depth is adjustable for 3/8”, 5/8”

and 1/2” thickness floor wood. To adjust the

floor plate depth, please follow these steps as

listed below:

Plastic Screws

(K)

Floor Plate

(L)

Disconnect the tool from the air source

whenever adjust the floor plate. Make

sure there is no fastener in magazine

before adjusting the floor plate.

MAINTENANCE

Any time inspection, maintenance, and

cleaning are done:

◆Disconnect the tool from the air source.

◆ Empty the magazine completely.

Disconnect the air supply from the tool to

add the lubricant.

LUBRICATION

Frequent, but not excessive, lubrication is

required for best performance after long

periods use. Oil for pneumatic fastening tools is

added through the air line connection and will

lubricate internal parts.

Turn the tool so the air inlet is facing up.

Place 2-3 drops of pneumatic fastening tool

oil into air inlet. Do not use detergent oils, oil

additives, or air-tool oils as these lubricants

will cause accelerated wear to the seals and

bumpers in the tool, resulting in poor tool

p e r f o r m a n c e a n d f r e q u e n t t o o l

maintenance.

After adding oil, connect the tool to the air

source, run tool briefly. Wipe off any excess

oil from the cap exhaust.

Each tool is packed with an anti-dust cap on the

air connector, check it after unpacking.

Keep the anti-dust cap cover the air connector

when the tool is not in use.

ANTI-DUST

oil

Too Shallow

Flush

Adjustment

wheel(J)

FIRING THE TOOL

(SEQUENTIAL FIRING MODE)

Single sequential actuation provides the most

accurate fastener placement.

To use the tool to drive nails in this actation

mode, WCE and trigger must be used in a

specific order.

Connect the tool to the air source.

The work contact element(WCE) must be

completely depressed by placing the nose

of the tool against the work piece.

The trigger must be pulled firmly and then

released.

The trigger must be released to reset the

tool before another fastener can be driven.

The tool must be allowed to recoil away

from the work piece.

An improperly functioning tool must not

be used. Do not actuate the tool unless

the tool is placed firmly against the

work place.

Always know the operational mode of

the tool before using. Failure to know

the operational mode could result in

death or serious personal injury.

During normal use, the tool will recoil

immediately after driving a fastener.

This is a normal function of the tool. Do

not attempt to prevent the recoil by

holding the tool against the working

surface. Restriction to the recoil can

result in a second fastener being driven

from the tool. Grip the handle firmly and

let the tool do the work. Failure to heed

this warning can result in serious

personal injury.

HTTP://WWW.NUMAXTOOLS.COM 1-888-669-5672

HTTP://WWW.NUMAXTOOLS.COM 1-888-669-5672

10 11

MODEL: SFBC940 MODEL: SFBC940

1.

2.

3.

4.

5.

!

WARNING:

1.

2.

3.

4.

5.

Note:

Pull the trigger, then depress the WCE on

working surface, the tool CANNOT operate.

This is considered to be more restrictive mode

of operation, suitable for less experienced

users.

Please don’t use the tool for wood density over

3

0.7g/cm .

!

WARNING:

!

WARNING:

!

WARNING:

1.

2.

3.