Owner manual

Section C: Principle of Operation 5

C: PRINCIPLE OF OPERATION

Thank you for purchasing a Perma Pure Baldwin™-Series eCOOL™ 5000XP Series

Digital Thermo-Electric Cooler CSA-C and CSA-US certified for Class I Division 2

Groups A,B,C,D hazardous locations. The eCOOL™ 5000XP Series has numerous

features including:

Remote monitoring and control of heated filter probe, heated sample line, and sample

conditioning system.

eCOOL

™

interface software included for monitoring and control over the Internet or a

Local Area Network.

A jumbo 2-line LCD display with multi-colored LED’s provides easy local monitoring and

control of your sample handling system.

Alarm notification of over / under temperature, thermocouple failure, and water slip

(moisture carryover).

Alarm relay shuts off the sample pump to protect expensive analyzers from water slip

(moisture carryover).

Eliminates the cost and complexity of separate temperature controllers such as for a

heated sample line and filter probe.

Extra thermocouple inputs and outputs available.

Operates with 110/120VAC, 220/240VAC, 12VDC, 15VDC, or 24VDC.

Field friendly, requires virtually no maintenance, and is backed by our 1-year limited

warranty.

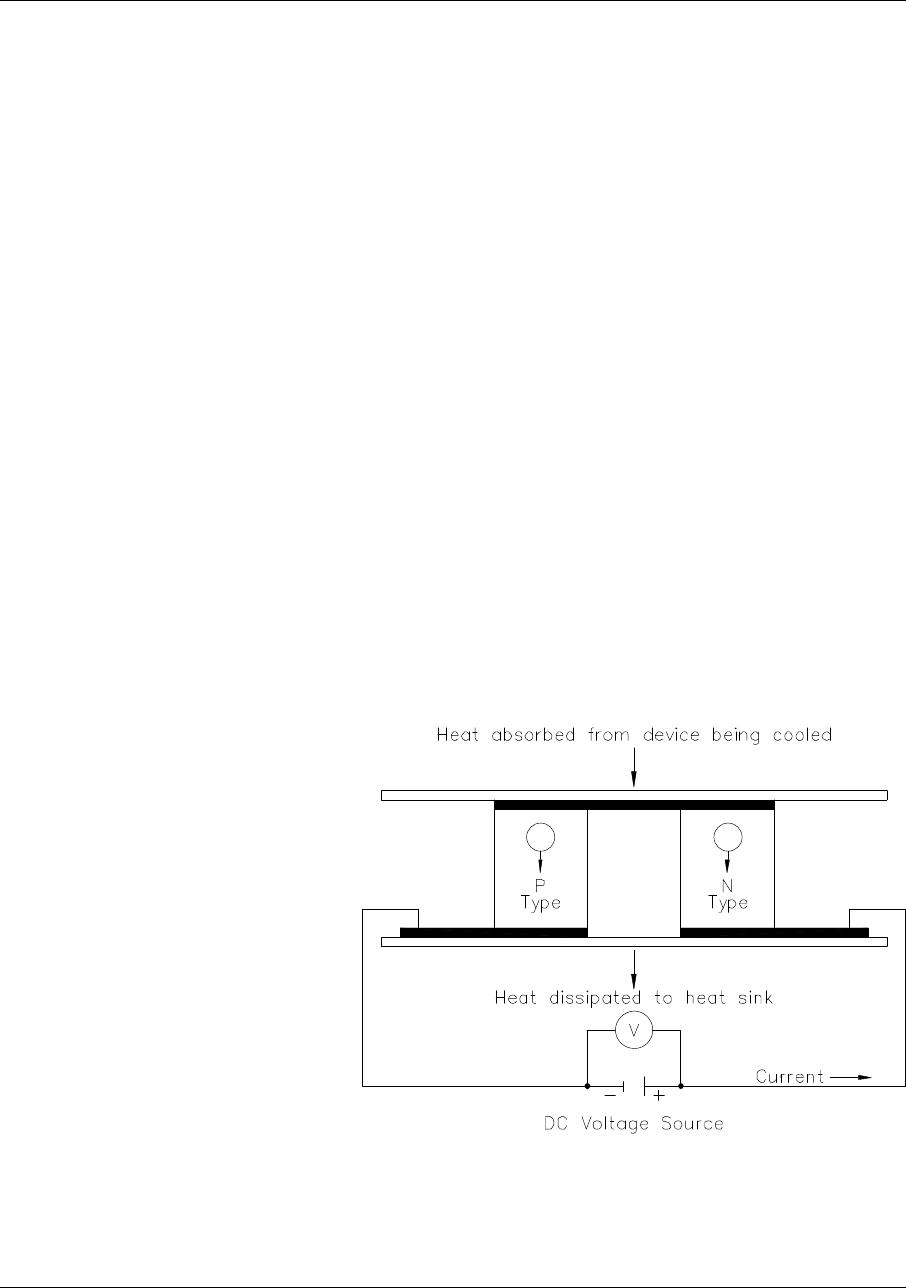

All Baldwin-Series coolers use thermo-electric elements (Peltiers) to cool the sample

gas to the desired dew point temperature. A thermo-electric cooler is best illustrated

as a small heat pump with no

moving parts. The Peltiers

operate on direct current and

may be used for heating or

cooling by reversing the

direction of current flow. This is

achieved by moving heat from

one side of the module to the

other with current flow and the

laws of thermodynamics. A

typical single stage Peltier

(figure 1) consists of two

ceramic plates with p- and n-

type semiconductor material

(bismuth telluride) between the

plates. The elements of

semiconductor material are

connected electrically in series and thermally in parallel.

Figure 1: Thermo-electric element (Peltier)