Replacement Part List

20

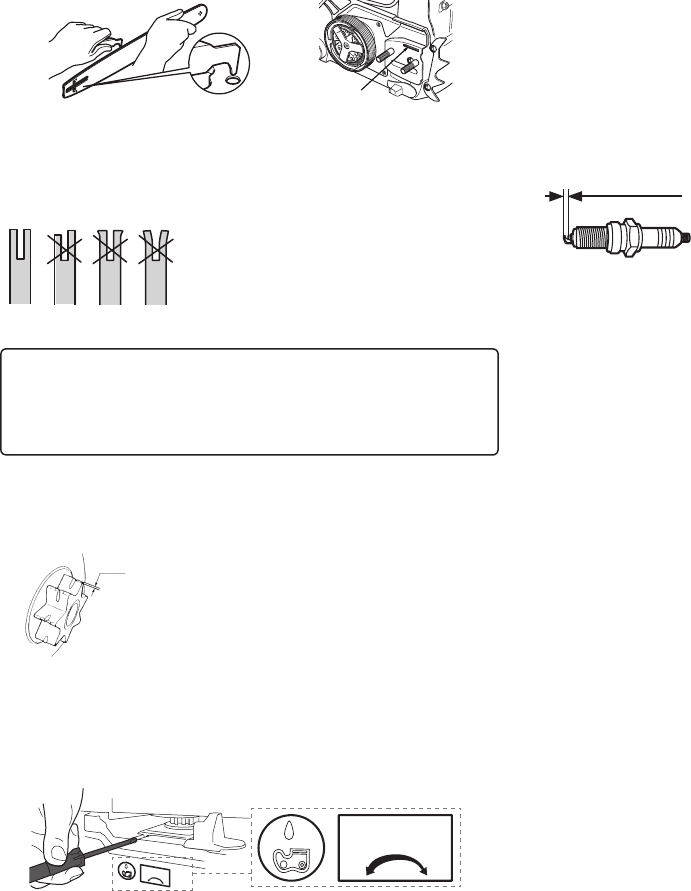

Guide plate

Oil hole

OF

F

Clean it before use.

• Clean the groove of the guide plate with the screwdriver.

• Clean the oil hole with the thin iron wire.

• Reverse the guide plate on a

regular basis.

• Check the sprocket and clutch and

clean the guide plate connection

before installing the guide plate.

• Replace the worn guide plate.

Attention

ContactPOWERKING forreplacementoftheguide

plateorsawchain.

Clutch shell

If the clutch shell is damaged, the saw

chain will be damaged or worn too

early.

• If the sprocket clutch shell is worn

0.5mm or more, replace it.

• Check the clutch shell before

replace the saw chain. Replace the

worn clutch shell.

Oil pump

CHAIN OIL

MAX

MIN

CHAIN OIL

MAX

MIN

The capacity of the oil pump, which is set before delivery of the

saw chain, is about 7ml/min when the engine speed is 7,000rpm.

Rotate the adjusting screw counterclockwise to increase the

oil amount. The oil amount is the largest (13ml/min when the

engine speed is 7,000rpm) when the adjusting screw cannot be

rotated due to the effects of the stopper.

Do not rotate the adjusting screw when the oil amount is the

largest or smallest.

Spark plug

Check it on a regular basis.

• The standard spark plug gap is 0.6

- 0.7mm.

• If the spark plug gap is more or less than the standard

value, correct it.

Tightening torque: 15 - 17N.m (150 - 170kgf/cm)

Magneto

The machine is equipped with a CDI ignition system (capacitor

discharge ignition device).

Check whether the wire is connected rmly.

Cylinder cooling ns

Check the ns on a regular basis.

If the cooling ns are blocked, the engine cooling effects will be

weakened. Clean dust and dirt of cooling ns to strength cold

air circulation.

0.5mm

0.6mm-0.7mm