Replacement Part List

22

Chain Saw Maintenance

Do not use the chain saw with the

blunt or damaged chain. If high

pressure is required during operation

of the chain saw and sawdust is ne

instead of large chippings, check

whether the edge on the chain is

damaged. Grind the edge to keep the edge angle the same as that

of new product. The service life of the chain can be prolonged

by grinding the edge. Check whether the chain saw is damaged

or worn each time after fuel lling.

If the chain teeth are less than 4mm long as a result of wear,

replace the chain.

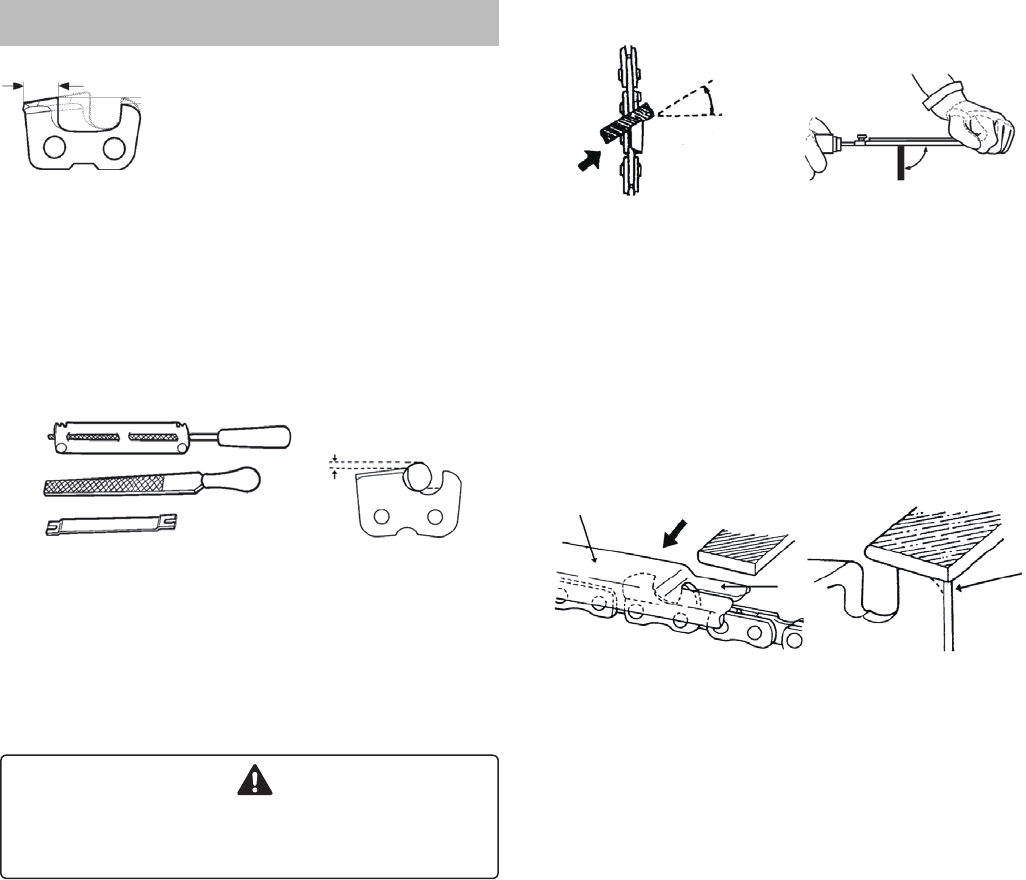

Grinding tools

A

B

C

1/5

The following tools are required to properly grind the chain.

A. Round le and clamp

B. Flat le

C. Depth gauge

Use the le (4.0mm round le) and clamp of appropriate

specifications to achieve good grinding effects.

Consult POWERKING for appropriate grinding tools and

specifications.

Warning Danger

• Shutdowntheenginebeforegrindingthechain.

• Weartheconforminglaborprotectiongloves.

Grinding precautions

2

3

30-degree

90-degree

4

1. Fix the chain and push the hand guard forwards. Push the

hand guard in the opposite direction of the front handle to

rotate the chain.

2. The cutting edges for operation of the chain with the left

and right hand are distributed alternately. Grinding must

be done from inside to outside.

3. Keep the angle of the le clamp and the linear parallelism

of the chain location and le the back of the cutting edge

until the damaged part (lateral or top part) is ground.

4. Keep the le parallel.

5. Sharpen the seriously worn edge at rst, and then grind all

the edges to the same length.

1

3

4

1. The wood cutting thickness depends on the grinding

depth. Therefore, the chain must be properly maintained

during operation.

2. If the length of the cutting edge is reduced, the bottom

height must be reduced at the same time.

3. Use the depth gauge for positioning, and le the

protruding part.

4. Round the front part of the bottom to smooth the cutting

process.

4mm

0.64mm