Manual

POWERWINCH RC 23 & RC30 TRAILER WINCHES

9

CABLE REPLACEMENT

WARNING ALWAYS USE THE EXACT POWERWINCH REPLACEMENT CABLE

(P/N P7188800AJ). WINCH RATING AND CABLE STRENGTH ARE MATCHED FOR SAFE

AND OPTIMUM PERFORMANCE

. NEVER REPLACE THE CABLE WITH ROPE.

CAUTION ALWAYS WEAR LEATHER GLOVES WHEN HANDLING THE CABLE. STEEL

CABLE CAN CAUSE SERIOUS DAMAGE TO HANDS

.

1. Unplug the wire harness from the winch.

2. Loosen the clutch knob (turn counterclockwise) and pull the cable out completely.

3. Cut the old cable off

approximately 2" from the cable

drum.

4. Slide the collar away from the cable

then push the old cable out of the

drum shaft.

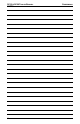

5. Insert the new cable through the

shaft. The cable must be inserted

through the side opposite the

counter bore.

6. Insert the stop sleeve over the

end of the cable until the cable is

flush with the end of the stop.

Solder or crimp the stop onto the

cable.

7. Pull the cable back through the shaft until the stop is seated in the counter bore of

hole.

8. Slide the collar around the cable. The notch on the collar fits around the cable.

9. Tighten the clutch control knob clockwise until finger tight to set the brake.

D

O NOT over tighten the clutch knob; over tightening can cause damage to

the clutch.

10. Reconnect the harness to the unit. Power-in the cable, keeping tension on the

cable as it is winding.

CAUTION

IF THE CABLE IS NOT WOUND CORRECTLY, IT MAY CAUSE LOSS OF POWER AND RISK DAMAGE TO

THE LEVELWIND PLATE

. IF THE CABLE IS NOT CORRECT (TOO LOOSE OR WOUND ON ONE SIDE),

UNWIND THE CABLE THEN REWIND WHILE KEEPING TENSION ON THE CABLE

.

Stranded Cable

Stop Sleeve

Crimp or Solder

Over End of Cable

Completed Installation

Counterbore

Drum Collar

Drum Flange

pwRC013