Installation Guide

INSTALLATION

GUIDE

1

approx 60mm (2 3/8”) backset

2

3

5

HEAD JAMB

6

DOOR JAMB MAGNETIC ASSEMBLY

DRILLING TEMPLATE GUIDE

POWER ADJUSTMENT SPACER RINGS

(S/STEEL)

'DRILL IN' RUBBER BUFFERS AND

S/STEEL 10g FIXING SCREWS

SELF ADHESIVE S/STEEL COVER

PLATES

DOOR MAGNETIC ASSEMBLY

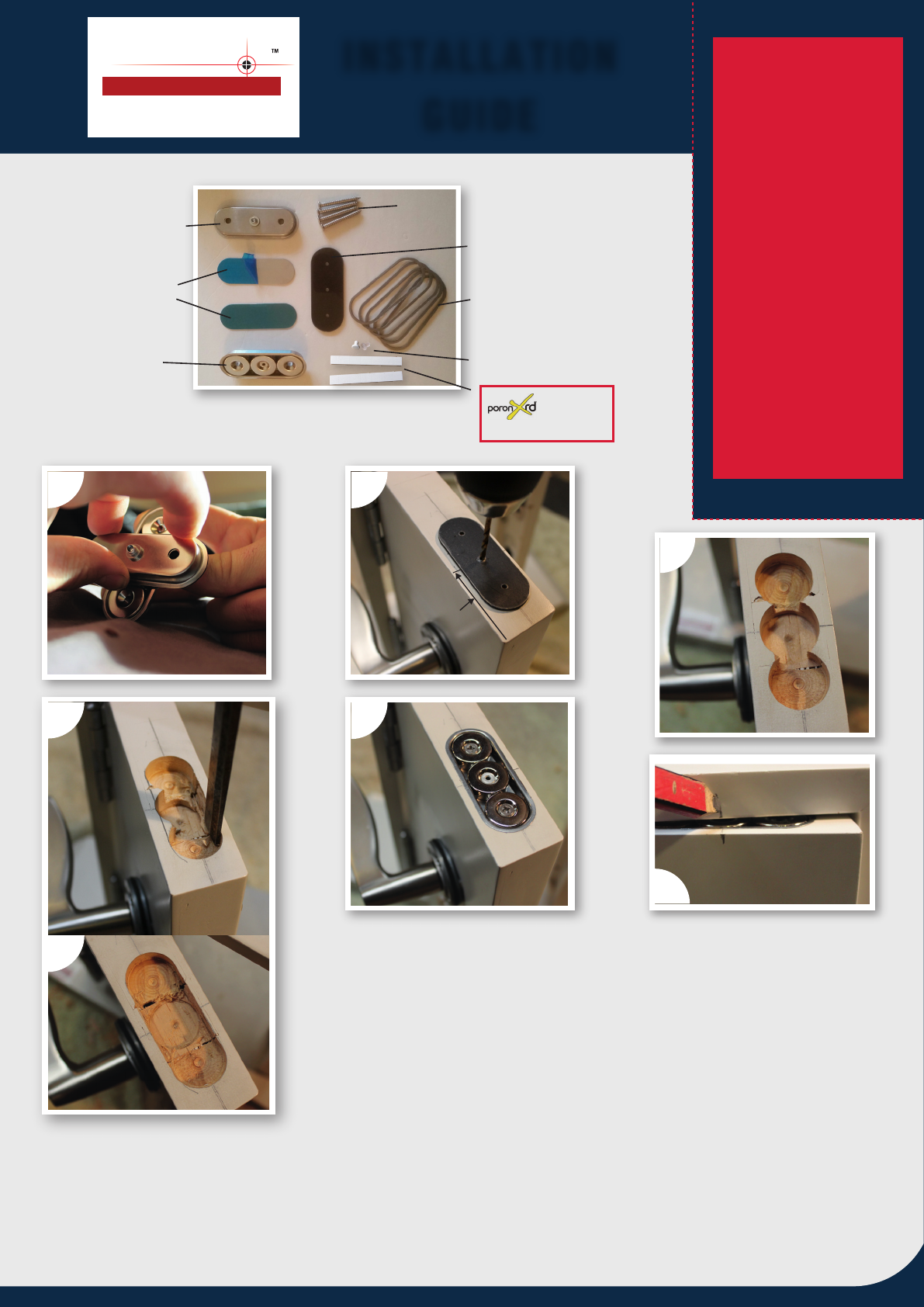

1. Remove magnetic assemblies from packaging. To separate assemblies twist apart sideways.

Keep magnetic assemblies at least 1 metre apart (and away from any steel objects) until secured

into door and jamb.

2. Measure and mark a centreline onto the top edge of the door. Measure and mark a backset of approx.

60mm (2 3/8") from the 'leading edge' of the door. Position the plastic DRILLING TEMPLATE GUIDE on the

top of door so the templates middle hole is lined up over the intersecting centreline and 'backset mark'.

Drill 3 x Ø3mm (1/8") pilot holes through the template into the centreline.

3. Using the Ø3mm (1/8") pilot holes as guides, drill 3 x Ø24mm (15/16") overlapping holes into the top of

door, to a depth of approx. 10mm (3/8"). (RECOMMENDED: FB-24 FORSTNER DRILL BIT- SOLD SEPARATELY).

4. Mark straight lines along the outer edges of the overlapping holes, then chisel where marked to create a straight sided recess. (4a)

5. Insert DOOR MAGNETIC ASSEMBLY into top of door and secure with 2 x screws provided.

Be careful not to over tighten screws as this may cause the flanged housing cups to deformand/or cracking in timber.

6. Close the door, then transfer the 'backset mark' up onto the head jamb.

4

4a

Precisi n

PLS24PRO-XHD

EXTRA HEAVY DUTY

CONCEALED MAGNETIC CATCH

Patent No. 568456

No. 8,864,188

FOAM STRIPS

(Sold separately)

WARNING use extreme

caution when handling

magnets as the attractant

forces are very powerful

and if allowed to snap

together violently, small

sharp chips can be thrown

off.

Do not attempt to remove

individual magnets from

assembly housing cups, as

this may result in magnet

breakage or personal

injury.