Installation Guide

3

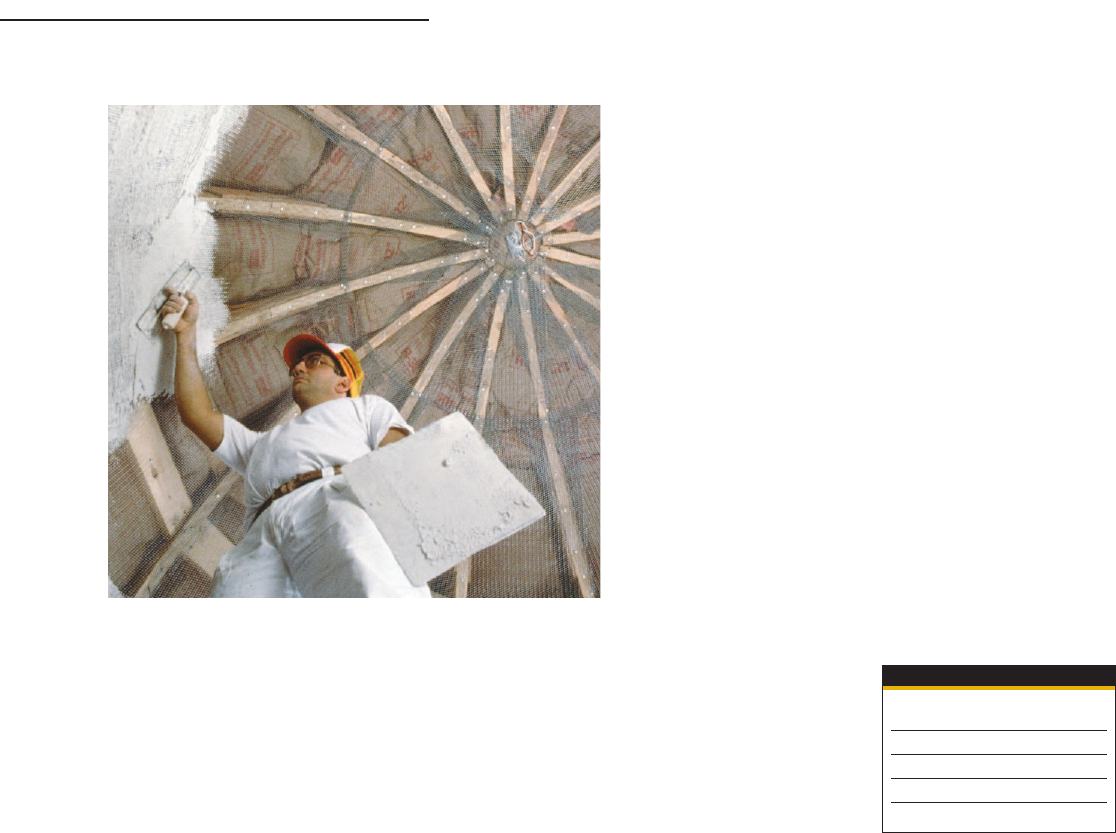

Lath & Plaster

Description

Conventional gypsum lath and

plaster systems have long been

considered the industry standard

in wall construction.

Ideal for both residential and

commercial applications, lath and

plaster systems provide smooth,

high quality wall surfaces, regardless

of framing alignment.

Lath and plaster deliver exceptional

beauty and durability in interior

partitions and non-loadbearing

exterior walls. Conventional plaster

systems are also commonly used

as the panel material for radiant

heating systems in ceilings.

When used with expanded metal

lath, conventional plasters create

a mechanical bond for maximum

strength and durability. Gypsum

plasters are also excellent for

sculpting, casting decorative

objects, and historic restoration.

General Uses

Gypsum plaster systems are suitable

for all interior plastering except

areas directly exposed to free

water or severe moisture. Lath

and plaster is not recommended

for exterior applications such as

carports, soffits and open porches.

Gypsum plasters are non-com-

bustible and act to prevent passage

of intense heat from fire for extended

periods. For specific fire resistance

ratings, see National Gypsum’s

Gypsum Construction Guide

.

Features/Benefits

m

Provides a smooth, high quality

surface

m

Requires no joint taping and

finishing

m

Resists nail pops better than

gypsum wallboard

m

Enhances overall wall strength

m

High impact and abrasion

resistance

m

Masks framing components and

mechanical service areas

Selecting

Plaster Bases

National Gypsum Company manu-

factures all of the most common

types of gypsum base plaster and

finishing plaster.

These products perform well

in appearance, structural ability,

sound isolation and fire endur-

ance ratings, allowing architects to

design virtually any number of

ceilings and partitions.

Performance

The relative performance of gypsum

and metal lath varies depending

on the type of construction. When

plaster on metal lath forms a mem-

brane, as in a suspended ceiling or

hollow partition, it’s more subject

to cracking than plaster on gypsum

lath. On solid partitions, metal lath

is generally less subject to plaster

cracking than gypsum lath.

Recommendations

m

Control joints should be installed

in ceilings without perimeter

relief with a maximum distance

between joints of 30' with a

maximum undivided area of

900 sq. ft. With perimeter relief,

the maximum distance between

joints is 50' with a maximum

undivided area of 2500 sq. ft.

On side walls, control joints

should be installed every 30'.

m

Where dissimilar plaster bases

adjoin, use strip-metal lath with

15 lb. felt paper between the

metal lath and underlying base.

m

Carefully inspect all lath and fur-

ring before plastering to ensure

adherence to job specifications

and good practice standards.

m

Select from the suggested

specifications that accompany

the description of each system.

PRODUCT SHELF LIFE

Storage/

Product Shelf Life

Two-Way Hardwall 6 months

Gypsolite

®

Plaster 6 months

Gauging Plaster 3 months

Molding Plaster 3 months

09 23 00/NGC