Installation manual

Page 18

Good, reliable operation with a minimum of service, starts with attention to the small

details:

Oil:

1. Setting the nozzle position and electrodes "by the book" using the

manufacturer's gauges.

2. Installing a quality micron filter at the burner.

3. Making careful/tight flare connections, without couplings, on oil suction

line.

4. Checking fuel pump pressure.

5. Checking draft at the breeching to insure it is adequate to overcome flue

gas resistance. (-.02 to –.04 in. w.c.)

6. Setting the air band properly with well maintained instruments. A good

target is 11% to 12.5% of (CO

2

) or 6.5% to 3.8% of (O

2

).

To ensure proper burner setup, gauges should be used to check things such as the

pump pressure, CO

2

levels, etc…

Gas:

1. Checking the electrode, orifice size, and flame rod settings against

manufacturer’s specs to insure proper operation.

2. Installing properly sized gas piping according to BTU input required and

length of gas line run.

3. Making sure there is proper manifold pressure before and after the

gas valve using a calibrated manometer.

4. Checking draft at the breeching to insure it is adequate to overcome flue

gas resistance. (-.02 to –.04 in. w.c.)

5. Setting the air band properly with well maintained instruments. A good

target is 9.5% to 10.5% of (CO

2

) or 5% to 2.5% of (O

2

) for natural gas, or

10.0% to 12.0% of (CO

2

) or 5% to 2.5% of (O

2

) for LP gas.

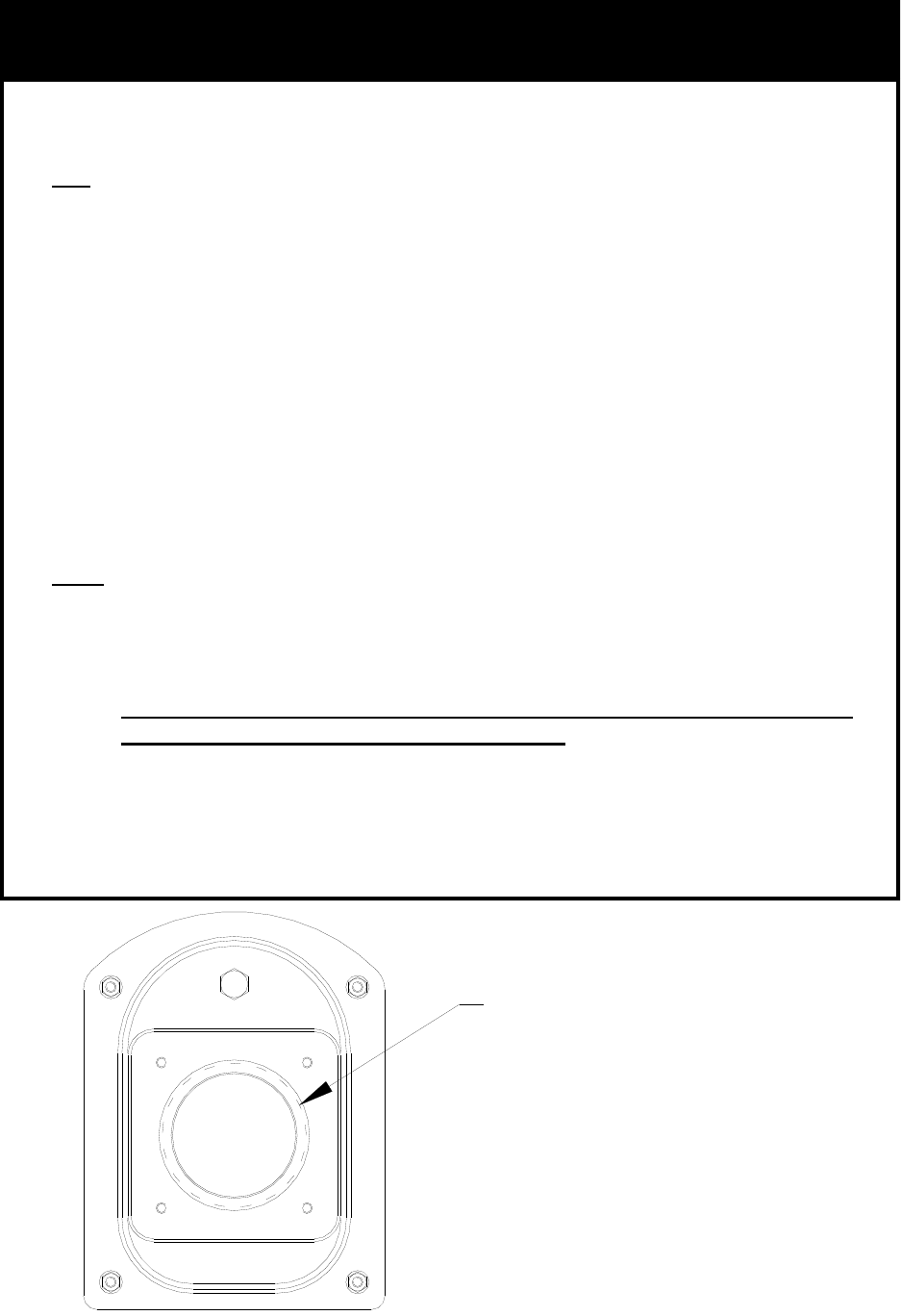

8. Burner Setup

CUT INSULATION IN BLAST

TUBE OPENING TO 4.25"

TO ACCEPT CARLIN BLAST

TUBE.

TRIM INSULATION IN

BOILER DOOR OPENING

TO 4.25” FOR BECKETT AFG

BLAST TUBE.