User guide

Table Of Contents

RL I&M MANUAL/EN/06.17.09

13/18

This document and the information contained herein, is the exclusive property of R&M Materials Handling, Inc., and represents a non-public, confidential and proprietary trade secret

that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling, Inc.

Copyright © (2009) R&M Materials Handling, Inc. All rights reserved.

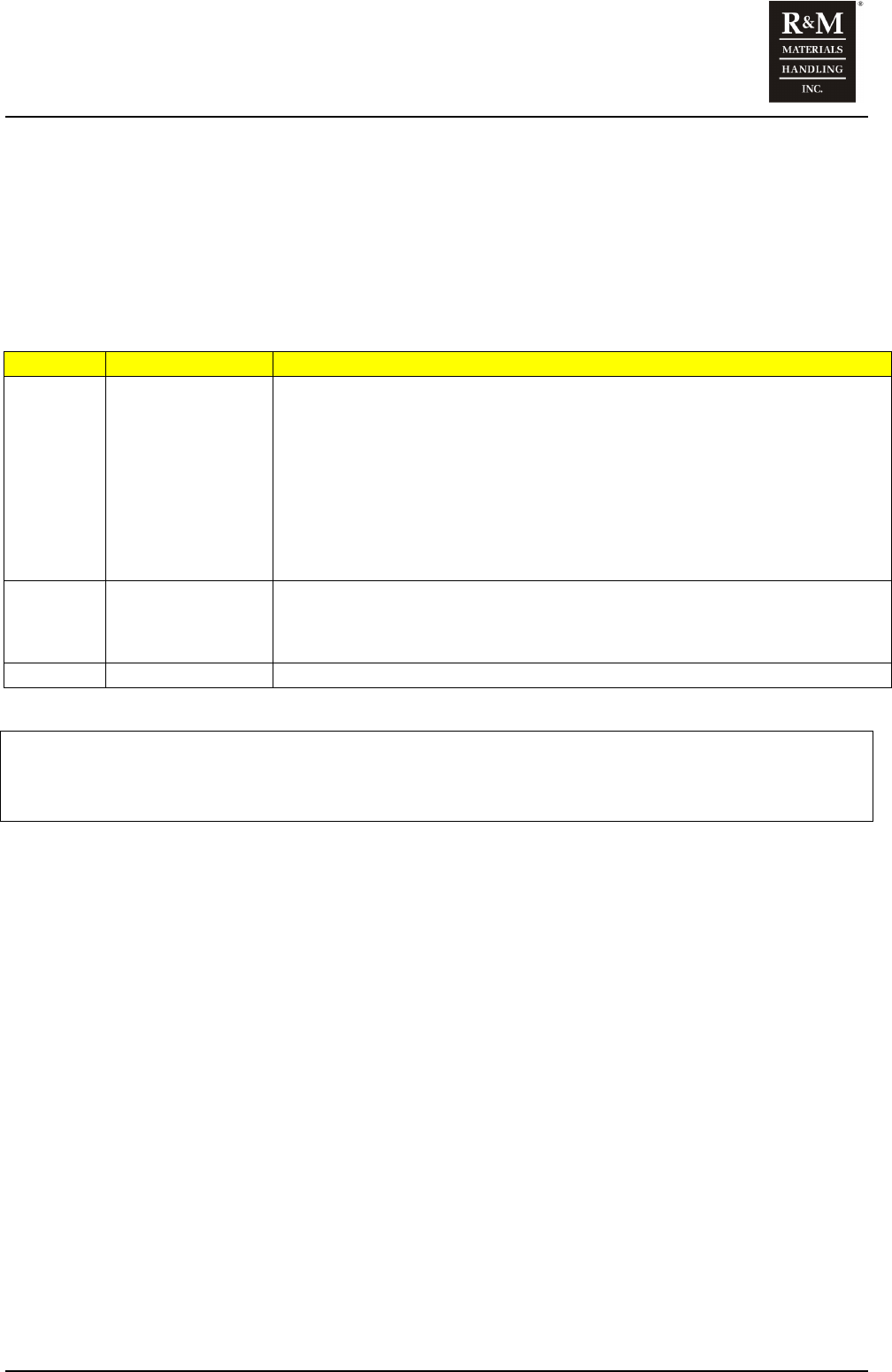

5 PREVENTATIVE MAINTENANCE

5.1 Maintenance Schedule

The maintenance and inspection intervals are based on normal duty under normal environmental conditions

(free from excessive dust, moisture, and corrosive fumes). If duty is heavier or environment more severe,

maintenance and inspection intervals should be shortened and more frequent.

Table 3. Maintenance Schedule

Interval Type of Check Inspection / Maintenance

1 month Visual examination

Check the external condition of the unit

Check the condition of the mechanism

Check the condition of the load chain and the attachments

Check the condition of the hooks

Check the condition of the hook safety latch

Check the condition of accessories

Clean the dust from the equipment

Check the greasing:

Lubricate the load chain with a brush (oil grade SAE 80)

Use oil to lubricate the heads of the hooks

6 month In-depth

examination

Check the operation of the brake

Check the condition of the load wheel

Inspect the load chain for wear or distortion

Inspect the hooks for wear or distortion

12 month Maintenance

Open the gear cover and grease the gears

Note: Always keep the chain clean and free of debris. Clean as necessary with paraffin or

diesel, drain and re-oil. Do not clean the chain with thinners or degreasing agents under any

circumstances.