Application Guide

redlinetools.com

800.791.7542

192

Endmills - Technical Info

Endmills

- Tech Info

• RedLine HP Variable 4-Flute tools are designed for fast metal removal. We control vibration and chatter

through a unique dampening geometry and can handle faster speeds and feeds.

• Our HP Variable 4-flute tools can be ran wet or dry and can be used in a wide variety of applications, from

roughing and finishing to slotting and pocketing.

• Designed to run in a wide range of materials from cast irons and steels to titanium and high temperature alloys.

• These High Performance tools can be found on pages 43-46, 56.

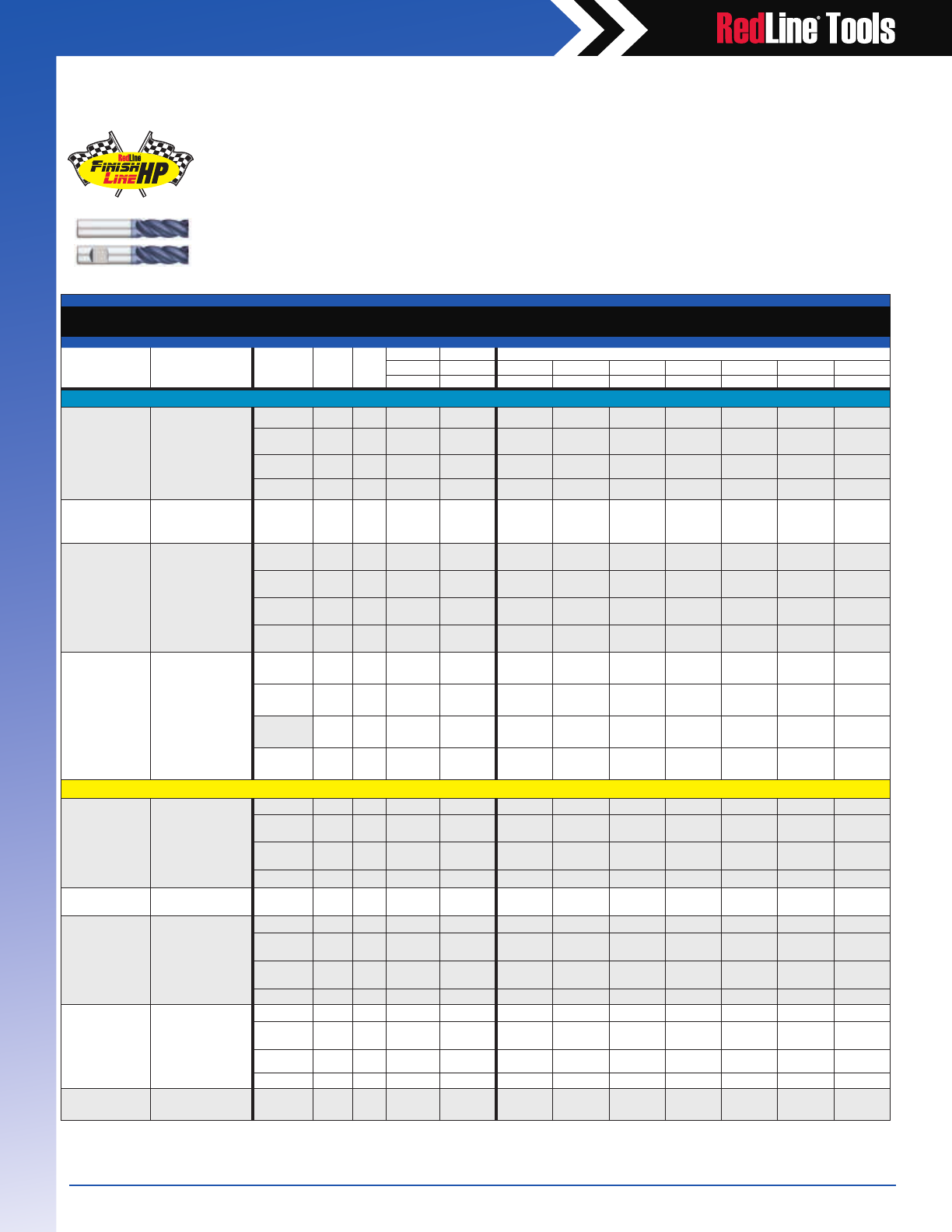

4-Flute, High Performance, Variable Index Endmills, Square,

Corner Radius & Ball End, 38 Degree Helix

HP Variable Index 4-Flute Tools Speeds & Feeds (Cont’d)

Material Grades Cut Type

Axial

DOC

Radial

DOC

Stub/Regular Long/X-Long Feed by Endmill Diameter (IPT)

SFM SFM 1/8 1/4 3/8 1/2 5/8 3/4 1

AlCrNX AlCrNX (.1250) (.2500) (.3750) (.5000) (.6250) (.7500) (1.000)

P - Steels

High Strength Tool

Steel

A2, D2, P20, H11, H13,

S2, 01

Slotting 1 x D 1 x D 300-360 210-250 .0004-.0008 .0014-.0016 .0017-.0019 .0026-.0028 .0029-.0031 .0035-.0037 .0039-.0041

Peripheral -

Rough

1.25 x D .3 x D 300-360 210-250 .0004-.0008 .0014-.0016 .0017-.0019 .0026-.0028 .0029-.0031 .0035-.0037 .0039-.0041

Peripheral -

HEM

2 x D .15 x D 300-360 210-250 .0008-.0016 .0018-.0032 .0024-.0038 .0032-.0056 .0038-.0062 .0048-.0074 .0058-.0082

Finish N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

High Strength Tool

Steel > 32 HRC

Reduce SFM by 40% N/A N/A N/A 180-216 126-150 N/A N/A N/A N/A N/A N/A N/A

Low Carbon

A36, 12L14, 12L15,

1005, 1018, 1020,

1108-1119, 1213-

1215, 1513-1518,

4012, 5015,

9310

Slotting 1 x D 1 x D 560-660 400-550 .0004-.0008 .0018-.0020 .0030-.0032 .0035-.0037 .0039-.0041 .0041-.0043 .0054-.0056

Peripheral -

Rough

1.25 x D .5 x D 560-660 400-550 .0004-.0008 .0018-.0020 .0030-.0032 .0035-.0037 .0039-.0041 .0041-.0043 .0054-.0056

Peripheral -

HEM

2 x D .15 x D 560-660 400-550 .0008-.0016 .0036-.0040 .0060-.0064 .0070-.0074 .0078-.0082 .0082-.0086 .0108-.0112

Finish N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

Medium Carbon

1040-1095, 1140-

1151, 1330-1345,

1520-1572, 4023-

4063, 4120-4161,

4330-4340, 4620-

4640, 8620-8660,

8740-8750,

6150, 51000, 52100

Slotting 1 x D 1 x D 525-630 380-520 .0004-.0008 .0018-.0020 .0030-.0032 .0035-.0037 .0039-.0041 .0041-.0043 .0054-.0056

Peripheral -

Rough

1.25 x D .5 x D 525-630 380-520 .0004-.0008 .0018-.0020 .0030-.0032 .0035-.0037 .0039-.0041 .0041-.0043 .0054-.0056

Peripheral -

HEM

2 x D .15 x D 525-630 380-520 .0008-.0016 .0036-.0040 .0060-.0064 .0070-.0074 .0078-.0082 .0082-.0086 .0108-.0112

Finish N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

M - Stainless Steels

Austenitic

301-304L, 310, 316L,

321, 347

Slotting 1 x D 1 x D 300-360 210-250 .0004-.0008 .0014-.0016 .0017-.0019 .0026-.0028 .0029-.0031 .0035-.0037 .0039-.0041

Peripheral -

Rough

1.25 x D .3 x D 300-360 210-250 .0004-.0008 .0014-.0016 .0017-.0019 .0026-.0028 .0029-.0031 .0035-.0037 .0039-.0041

Peripheral -

HEM

2 x D .10 x D 300-360 210-250 .0008-.0016 .0018-.0032 .0024-.0038 .0032-.0056 .0038-.0062 .0048-.0074 .0058-.0082

Finish N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

Austenitic > 32

HRC

Reduce SFM by 20% N/A N/A N/A 240-288 168-200 N/A N/A N/A N/A N/A N/A N/A

Martensitic

403, 410, 416, 420,

430, 431, 440

Slotting 1 x D 1 x D 300-360 210-250 .0004-.0008 .0014-.0016 .0017-.0019 .0026-.0028 .0029-.0031 .0035-.0037 .0039-.0041

Peripheral -

Rough

1.25 x D .3 x D 300-360 210-250 .0004-.0008 .0014-.0016 .0017-.0019 .0026-.0028 .0029-.0031 .0035-.0037 .0039-.0041

Peripheral -

HEM

2 x D .15 x D 300-360 210-250 .0008-.0016 .0018-.0032 .0024-.0038 .0032-.0056 .0038-.0062 .0048-.0074 .0058-.0082

Finish N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

Precipitation

Hardening

12/8, 15/5, 17/4, AM-

350/355/363, PH13-

8MO, PH14-8/MO

Slotting 1 x D 1 x D 300-360 210-250 .0004-.0008 .0014-.0016 .0017-.0019 .0026-.0028 .0029-.0031 .0035-.0037 .0039-.0041

Peripheral -

Rough

1.25 x D .3 x D 300-360 210-250 .0004-.0008 .0014-.0016 .0017-.0019 .0026-.0028 .0029-.0031 .0035-.0037 .0039-.0041

Peripheral -

HEM

1.5 x D .10 x D 300-360 210-250 .0008-.0016 .0018-.0032 .0024-.0038 .0032-.0056 .0038-.0062 .0048-.0074 .0058-.0082

Finish N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

Precipitation Hard-

ening > 32 HRC

Reduce SFM by 20% N/A N/A N/A

240-288 168-200 N/A N/A N/A N/A N/A N/A N/A

D = tool diameter. Reduce feed rates by 20% when using long length tools. Starting parameters shown. Speeds and Feeds listed are estimated and will vary by application.