Troubleshooting guide

INTELLI-VENT TROUBLESHOOTING GUIDE

Technical Training Department Ashland City, Tennessee © 2005

23 of 24

AIR PRESSURE SWITCH TESTING

To test the performance of an air pressure switch you must know the design activation point.

This will be a given pressure value, either negative (in a vacuum) or a positive pressure.

Contact the technical information center for this information or to locate a service handbook

for the product you are working on. A. O. Smith Water Heaters; 800 527-1953. State Water

Heaters; 800 365-0577. Have the complete model, serial, and series number on hand.

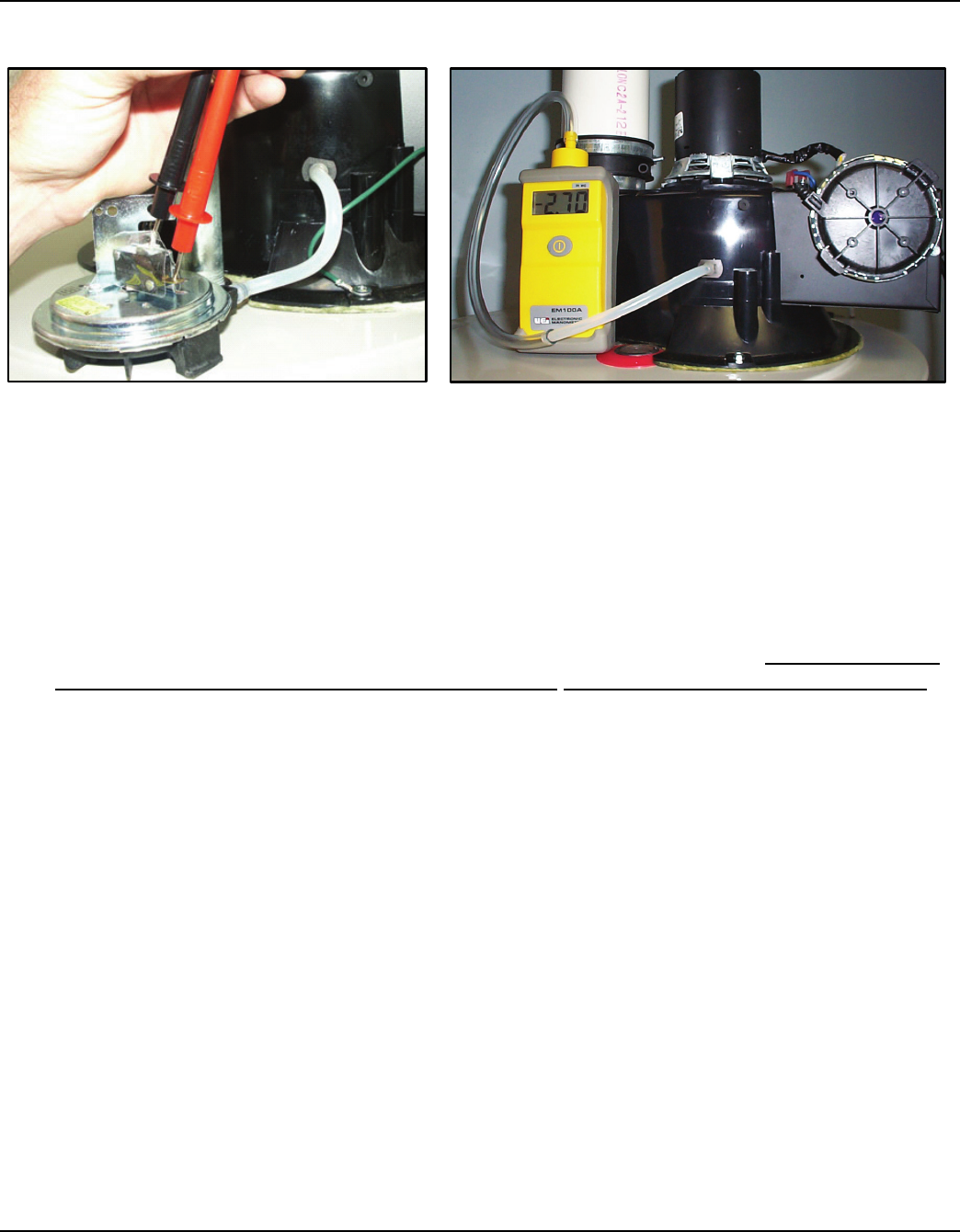

Testing air pressure switch performance requires a digital or incline manometer that will read

pressures at the expected activation point to within 1/100th of an inch of water column

(“W.C.) at times. Digital manometers are typically less expensive and quicker to use than

incline manometers. Manufacturers include Dwyer, UEI, and Bacharach. A good range of

operation would be -15.00” W.C. to +15.00” W.C. Must be sensitive to 1/100th “W.C..

With the sensing tube removed from the vent system sensing port, attach the manometer to

the port, start the water heater and when the blower comes up to speed record the pressure

reading. If the pressure reading does not reach the activation point for the pressure switch,

the vent system must be checked for restrictions, too many elbows, or too many equivalent

feet of piping. Consult the owners manual for complete venting requirements. Inspect/clean

the blower as necessary.

The state of the air pressure switch contacts can be checked with an ohm meter for

continuity.

A normal state test would be done with the power off and the wires to the switch removed. If

the switch is a normally open switch and the continuity test showed continuity through the

contacts; the switch is defective and must be replaced. A normally closed switch would be

defective if it showed no continuity under these conditions.

An operational test would be performed during blower operation with the wires to the air

pressure switch removed and the sensing tube attached at both ends. With an ohm meter

check continuity between the two wiring terminals on the pressure switch after the blower

comes up to speed. If the pressure reading taken previously is at or beyond the activation

point for the pressure switch and the pressure switch contacts do not activate, the pressure

switch is defective and must be replaced.

Taking an air pressure reading

Continuity test with ohm meter