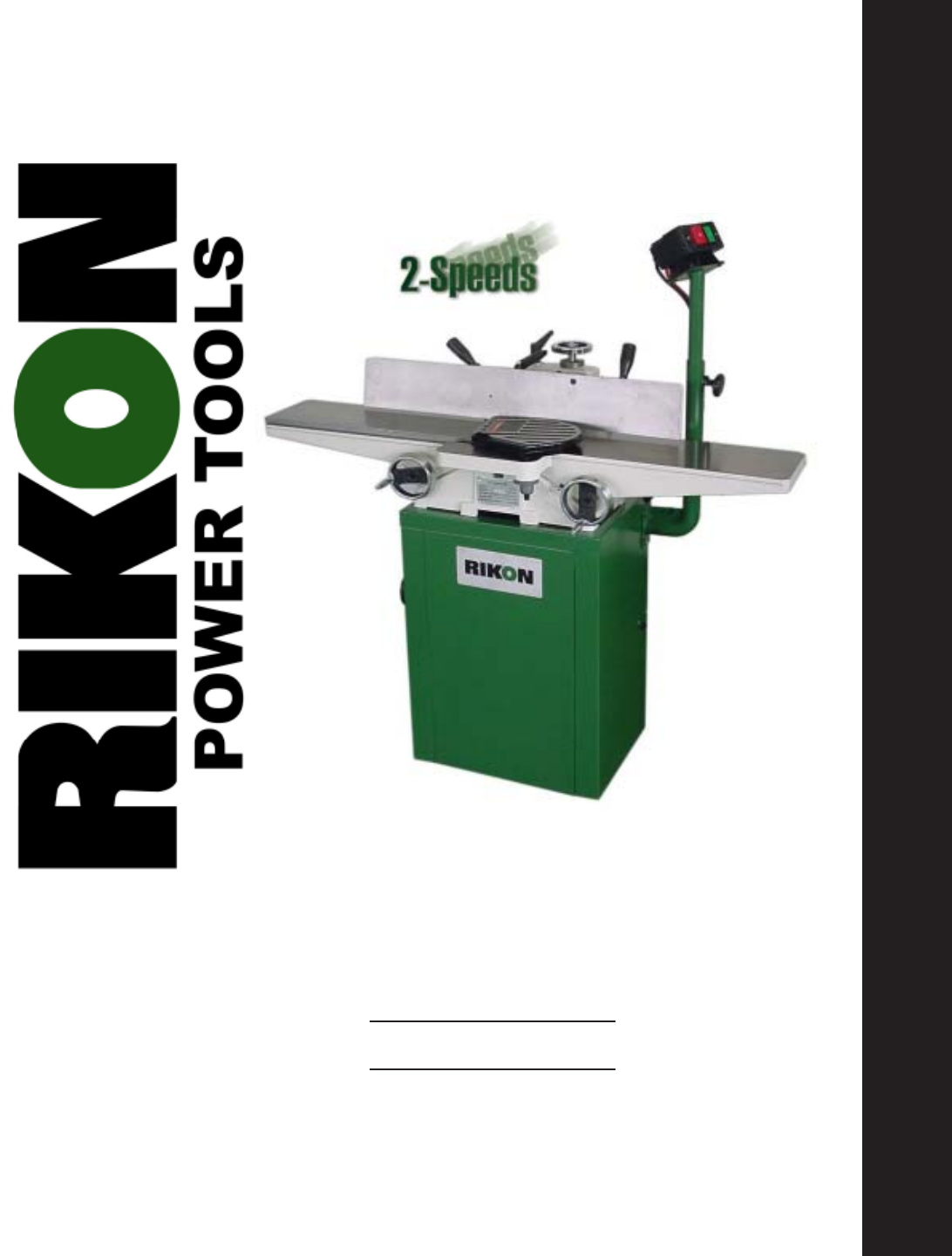

6” Jointer Owner’s Manual Model: 20-110 Record the serial number and date of purchase in your manual for future reference. Serial number: Date of purchase: For more information: www.rikontools.com Part # 20-110M2 or info@rikontools.com For Parts or Questions: techsupport@rikontools.

Operator Safety: Required Reading IMPORTANT! Safety is the single most important consideration in the operation of this equipment. The following instructions must be followed at all times. There are certain applications for which this tool was designed. We strongly recommend that this tool not be modified and/or used for any other application other than that for which it was designed. If you have any questions about its application, do not use the tool until you have contacted us and we have advised you.

ALWAYS DISCONNECT TOOLS. Disconnect tools before servicing and when changing accessories such as blades, bits, and cutters. ALWAYS AVOID ACCIDENTAL STARTING. Make sure switch is in “OFF” position before plugging in cord. NEVER LEAVE TOOLS RUNNING UNATTENDED. ALWAYS CHECK FOR DAMAGED PARTS. Before initial or continual use of the tool, a guard or other part that is damaged should be checked to assure that it will operate properly and perform its intended function.

Table of Contents Safety Warnings....................................................................................................................................2 Jointer Safety Rules ..........................................................................................................................3 Specifications ........................................................................................................................................4 Contents of Package ..........................

Unpacking and Checking Contents Note: Unit shipped in two cartons.

Loose Parts in Loose Bag 2 3 3/8” Flat Washers 3 3/8” Lock Washers 3 Mounting Bolts 1 3mm Hex Wrench 1 5mm Hex Wrench 1 8/10mm Open End Wrench 1 12/14mm Open End Wrench 4 Hex Head Screw M8 4 Hex Nut M8 2 1/8” Flat Washers 6 1/8”x3/8” Pan Head Screws 1 Blade Lock Tool 1 Blade Adjust Tool Tools Required for Assembly 1 Philips Head Screwdriver, 6-8” Adjustable Wrench, or 17 and 19mm Wrench, 9/16” Socket or 14mm with 6” Extension. Unpacking and Clean-up 1.

Getting To Know Your Jointer 4 8 15 3 5 2 10 6 14 12 9 7 1 13 1. 2. 3. 4. 5. 6. 7. 8. Hand Wheel for Out-feed Table Out-feed Table Fence Fence Adjustment Handle Cutter Guard In-feed Table Hand Wheel for In-feed Table On/Off Switch 9. Out-feed Table Lock Knob 10. Fence Tilt Lock Handle 11. Belt Guard 12. Fence Adjustment Lock Handle 13. Depth Limiter 14. In-feed Table Lock Knob 15.

Assembly Installing Bed to Stand 1. Remove rear door on cabinet. 2. Place bed assembly on top of stand. Be sure the pulleys face the rear of the cabinet. Ask a friend for assistance with this step. (DO NOT LIFT BY TABLE ENDS, LIFT FROM CENTER OF CASTING) (Fig. 1) 3. Line up the two holes in stand top with holes in the bed assembly by viewing through rear access door in stand. Figure 1 4. Attach stand to bed assembly by using two 3/8" lock bolts and washers. (See Fig. 2) Hand tighten only at this time. 5.

Installing Belt Guard 1. Place the belt guard over the belt opening in the stand. 2. Line up the holes in the stand with the holes in the guard. 3. Attach the guard to the stand using two 1/4-20x1/ 2" pan head screws and two 1/4" lock washers (See Figure 6) Figure 6 Install Fence Bed Casting 1. Use two 3/8" x 1-1/2" hex socket screws, and washers to attach the fence bed casting to the table bed. (Fig. 7) using 13mm socket/wrench. 2.

Mounting the On / Off Switch Mounting Hardware 1. Decide where you want to mount the on / off switch. It can be mounted on the in-feed side of the cabinet or the out-feed side. 2. Feed the two power cords through the cabinet (Fig. 10). Power Cords 3. Mount the power switch column to the cabinet using (4) 3/8” x 3/4” bolts, (4) washers and (4) 3/8” nuts using a 14mm socket/wrench and tighten. Figure 10 B 4. Plug the motor cords together (Green cords). A 5. Plug the power cords together (Black cords).

3. Adjust the fence to a 90º angle by releasing lock handle (B, Figure 14). E G C F 4. Place a combination square on the in-feed table to check that the fence is 90º to the table. D B 5. If fence is not square to table, release lock handle (D, Figure 14) and turn handle (C, Figure 14) until the fence is 90º A 6. Now that the fence is 90º to the table, adjust the positive stop screw assembly, (E, Figure 14) to maintain the 90º position. Te 14). Figure 14 7. Retighten lock handle (D, Figure 14).

Setting Out-feed Table to Cutter-head Knives WARNING DO NOT connect machine to power source at this time! Cutter-head blades are extremely sharp! Use Caution when hands are near the cutter-head! Failure to comply may cause serious injury! 1. Unplug the Jointer from the power source. Figure 16 2. Remove the blade guard by turning knob. (Figure 16) clockwise while lift up on the blade guard. Caution: Blades are sharp! Use care while working around the blades. 3.

8. If blade is higher or lower at the right of the table than it is at the left, slightly loosen four screws (Figure 20) by turning clockwise as viewed from the in-feed table. To lower, turn the screw clockwise. To raise, turn the screw counterclockwise. Blades are set at the proper height when the top of the blades are1/16" above the cutter-head. Alternately tighten four screws to hold each blade in place. 9. Repeat this process with blades two and three.

Installing Access Cover 1. Install access cover by placing bottom of panel into access in stand and fasten by turning latch knob. (Figure 22) Figure 22 Installing Dust Chute 1. Attach the dust chute (See Figure 23) to the base with four 1/4"-10x1/2"pan head screws and four washers.

Operation Maintenance CA UTION! CAUTION! BEFORE CLEANING OR CARRYING OUT MAINTENANCE WORK, DISCONNECT THE MACHINE FROM THE POWER SOURCE (WALL SOCKET). NEVER USE WATER OR OTHER LIQUIDS TO CLEAN THE MACHINE. USE A BRUSH. REGULAR MAINTENANCE OF THE MACHINE WILL PREVENT UNNECESSARY PROBLEMS. Keep the table clean to ensure accurate cutting. Keep the outside of the machine clean to ensure accurate operation of all moving parts and prevent excessive wear.

*********Warning********* Possible Cause Machine not plugged in Low Voltage Loose connection or open circuit in motor Motor overloaded Air flow restricted on motor Bad motor Pulley set screw loose Circuit overloaded with lights or other tools Circuit too long or undersized wires Voltage too low Circuit breakers do not have sufficient capacity Drive belt tension too high Use of extension cord Loose gibs Knives are set higher than the outfeed table Outfeed table set too high Table out of level One blade s

Cutterhead Assembly Index No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 Part No.

Fence Assembly 18

Fence Assembly Index No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 Part No. 1B 2B 3B 4B 5B 6B 7B 8B 9B 10B 11B 12B 13B 14B 15B 16B 17B 18B 19B 20B 21B 22B 23B 24B 25B 26B 27B 28B 29B 30B 31B 32B 33B 34B 35B 36B 37B 38B 39B 40B 41B 42B 43B 44B 45B 46B 47B 48B 49B 50B 51B 52B 53B 54B 55B 56B 57B Description Q’ty Fence Body Handle Hex Nut 10mm Hex Socket Bolt M8-1.

Stand and Motor Assembly 20

Stand and Motor Assembly Index No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 Part No.

Bed Assembly 22

Bed Assembly Index No. 1 2 3 4 5 6 7 8 9 10 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 43 44 45 46 47 48 49 50 Part No.

NOTES: 24

WARRANTY 2-Year Limited Warranty RIKON Power Tools/Richen Enterprise, Inc. (“Seller”) warrants to only the original retail consumer/ purchaser of our products that each product be free from defects in materials and workmanship for a period of two (2) years from the date the product was purchased at retail. This warranty may not be transferred.

For more information: 400 West Cummings Park, Suite 1000 Woburn, MA 01801 877-884-5167 / 781-933-8400 techsupport@rikontools.com www.rikontools.com Copyright Richen Enterprise, Inc.