Datasheet

Aluminum Electrolytic Capacitors

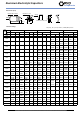

NO. ITEM SPECIFICATION

2. 6

Surge test

Rated surge voltage shall be applied (swich on) for 30 ± 5 seconds and

then shall be applied (swich off) with discharge for 5 ± 0.5 min at room

temperature . This cycle shall be repeated for 1000 cycles. Duration of one

cycle is 6 ± 0.5 minutes .

2. 7

Capacitance change : within

± 20% of the initial specified

value.

Dissipation factor : lessthan

200% of the initial specified

value.

The maximum A.C.current having frequency of 100K Hz which can be applied to

the capacitor at 105±2℃ continuously.Peak voltage not to exceed rated

D.C.voltage.

Leakage current :

within initial specified value.

3. Mechanical characteristics

NO. ITEM

SPECIFICATION

3. 1

Lead strength

(A) Tensile strength:

wire lead terminal:

d (mm)

≦0.45

0.5 ~ 0.8

0.8<d≦1.25

load (Kg)

0. 51

1.0 2.0

snap-in terminal:

d (mm)

load (Kg)

The capacitor shall withstand the constant tensile force specified

between the body and each lead for 10 seconds without damage

either mechani

cal or electrical.

(B) Bending strength:

wire lead terminal:

d (mm)

≦0.45

0.5 ~ 0.8 0.8<d≦1.25

load (Kg)

0. 25

0.51 1.0

snap-in terminal:

When the capacitance is

measured, there shall be

no intermittent contacts,

or open- or short- circui-

ting.

There shall be no such

mechanical damage

as

terminal damage etc.

With the capacitor in a vertical position apply the load specified axially to

each lead . The capacitor shall be rotated slowly from the vertical to the

horizontal position, back to the vertical position. The 90° in the opposite

direction and back the original position . Performance of capacitor shall not

have changed and leads shall be undaged .

Applicable

ripple

current

S>1

1.0

2. 5

0.5<S≦1

TEST METHOD

cross section area of

terminal (m㎡)

force

(Kg)

TEST METHOD

snap-in terminal

2.0

Distrelec Schweiz AG, Grabenstrasse 6, 8606 Nänikon, Switzerland, T +41 44 944 99 11, info@distrelec.com, distrelec.com