Specifications

7-3-3

FOR

TIMING ADJUSTMENT, THE FOLLOWING PROCEDURES USING A TIMING,TESTER:

Disconnect the stop button lead wires and the coil primary wire.

Remove blower housing from engine.

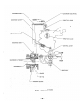

Connect the timing tester lead with red rubber cap to

the coil primary wire and ground the lead with black

rubber cap to crankcase. (See

Fig.

7-3-3.)

While the

points are open, the buzzer within tester remains ring-

ing and when the points are closed, the tester remains

silent.

Turn flywheel slowly counter-clockwise (D type and

V

type engines) or clockwise

(B

type engines) until the

buzzer within tester becomes silent.

Then, turn flywheel very slowly clockwise

(D

type and

V

type engines) or counter-clockwise (B type engines)

and stop immediately the moment the buzzer within

TIMI

\

GROUND

WIRE

tester begins ringing.

Fig.

7-3-3

Check

if

line mark

on

the flywheel

is

in

the line with line mark on the crankcase. When the line marks are in alignment,

the timing

is

correct.

If the timing mark lines are not

in

alignment, then readjust the point opening according to the BREAKER POINT

AD-

JUSTMENT, by-removing the flywheel and repeat the checking procedures

3)

through

S).

Afer completing the timing adjustment re-mount the blower housing and connect the coil primary lead to the stop button.

MAGNETO’

TROUBLE

SHOOTING

When the engine does not start or starts with difficulty, or when its operation is unstable, the following tests will clarify

if

they are caused by

a

defect in the magneto.

1) Check ignition cable for possible corrosion, broken, worn insulator or loose connection.

2)

Check the sparking as described later

in

this section.

3)

Check if the breaker points require cleaning, or adjusting

or

not.

If

the points are badly corroded or pitted. Condenser

may have to be replaced.

Refer to “BREAKER P0IN.T ADJUSTMENT”

4)

If no spark takes place, replace ignition coil.

SPARK

TESTING

Remove spark plug from cylinder head and place it on blower

housing,

with the ignition cable connected to it.

Crank the’ engine several times by starting pulley and observe the spark in the spark gap of spark plug. If the spark is strong,

the ignition system can be eliminated as the source of trouble.

If the spark is weak or there is no spark at all, repeat the checks according

to

the procedures

1)

through

3)

above. The

The correct electrode gap is

0.5

-

0.7

mm.‘ (Refer to section

12.

CHECKS and CORRECTION.”)

-31

-