User Manual

Table Of Contents

- 41 CHAPTER VIII: Troubleshooting

- CH II

- CH III

- CH IV

- CHV

- CHVI

- CHVII

- CHVIII

42

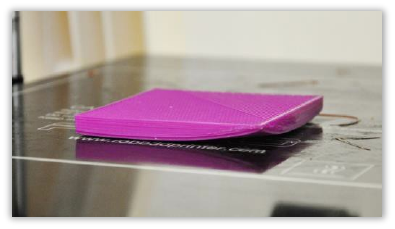

Warping

• Warping happens when the plastic cools and contracts. It is mainly seen in the bottom of the

print- where it is supposed to be stuck to the build plate.

• While an adhesion solution does help to prevent warping, heat is really the main contributing

factor. R1 3D printers come standard with a heated build platform, so if your heat settings are

correct for the type of material that you are printing with, you should never have to deal with

this issue.

• Having heat on your build plate keeps the plastic just below the point that it becomes solid,

which keeps it from hardening too quickly and separating from the bed.

• Using the “Brim” feature in your Slice Settings is another way to combat warping. This adds a

small feature that looks like the brim of a hat to the bottom of your print that can be broken

away after the print is finished.

• ABS plastic is much more temperamental as far as cooling goes than other types of plastic. This

is where you will see the most warping issues. Try not to use the print cooling fan for this

material. You can set this to be turned off in an ABS preset as we have described previously in

this guide.

Clogging

• Sometimes in 3D printing, your hot end may become clogged or jammed. This can happen for a

number of reasons and these are the main culprits:

- Not using the correct temperature settings. If the temp on the extruder is not high