User Manual

Table Of Contents

- 1747-6.8, Direct Communication Module User Manual

- Important User Information

- Summary of Changes

- Table of Contents

- Preface

- 1 - Overview

- 2 - Quick Start for Experienced Users

- 3 - Addressing

- 4 - Module Configuration

- 5 - Installation and Wiring

- 6 - Programming

- 7 - Troubleshooting

- 8 - Application Examples

- A - Specifications

- B - DCM Addressing Worksheet

- Index

- Back Cover

B

Appendix

B–1

DCM Addressing Worksheet

This appendix provides a worksheet for keeping track of the elements of each

I/O address for your system’s DCMs. Topics include:

• directions

• addressing review

In the table on the next page, enter the elements of each I/O address for each

DCM in your system. All DCM inputs and outputs are addressed with

respect to the SLC.

Make sufficient copies of this worksheet to cover all DCMs in your system.

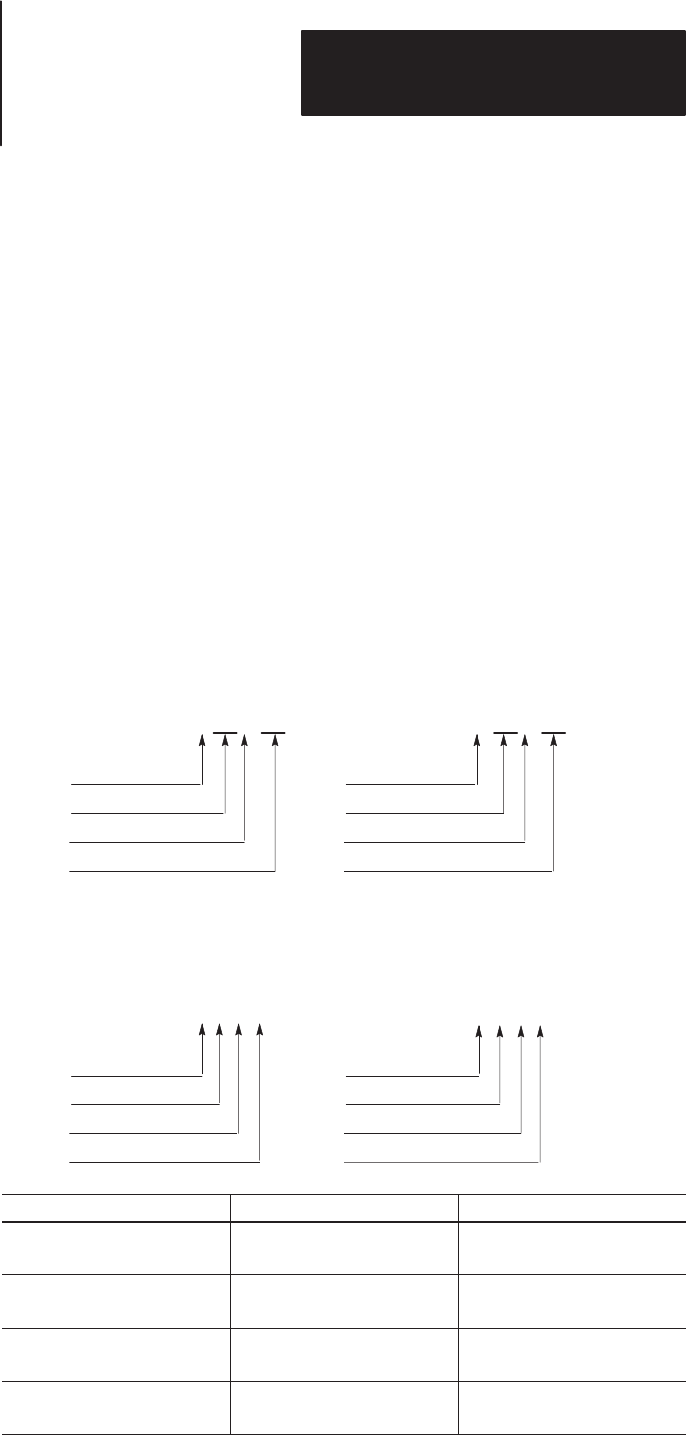

PLC Addresses

I = Input

O:017/10I:023/10

02 = Logical Rack

3 = I/O Group

10 = Bit (octal)

O = Output

01 = Logical Rack

7 = I/O Group

10 = Bit (octal)

PLC Input

Address

PLC Output

Address

SLC Addresses

I = Input

O:1.7/8I:2.3/8

2 = Physical Slot

3 = Word

8 = Bit (decimal)

O = Output

1 = Physical Slot

7 = Word

8 = Bit (decimal)

SLC Input

Address

SLC Output

Address

If you configure the DCM as: Then: Including the Status Word

1/4 Rack

1 data word (16 bits of I/O

data) is transferred.

Total transfer = 2 words

1/2 Rack

3 data words (48 bits of I/O

data) are transferred.

Total transfer = 4 words

3/4 Rack

5 data words (80 bits of I/O

data) are transferred.

Total transfer = 6 words

Full Rack

7 data words (112 bits of I/O

data) are transferred.

Total transfer = 8 words

Directions

Addressing Review