Instruction Manual

Table Of Contents

- 1769-UM006E-EN-P, Compact High-speed Counter Module User Manual

- Summary of Changes

- Table of Contents

- Preface

- 1 - Module Overview

- 2 - Module Operation

- 3 - Installation and Wiring

- 4 - Module Configuration, Output, and Input Data

- Configure the Module

- Configuration Array

- General Configuration Bits

- Filter Selection

- Program Mode and Program State Run

- Output Program Value (Out0ProgramValue through Out3ProgramValue)

- Output Fault Mode and Output Fault State Run

- Output Fault Value (Out0FaultValue through Out3FaultValue)

- Counter Maximum Count (CtrnMaxCount)

- Counter Minimum Count (CtrnMinCount)

- Counter Preset (CtrnPreset)

- Counter Hysteresis (CtrnHysteresis)

- Counter Scalar (CtrnScalar)

- Cyclic Rate Update Time (CtrnCyclicRateUpdateTime)

- Configuration Flags

- Range High Limit (Range0To11[n].HighLimit) and Range Low Limit (Range0To11[n].LowLimit)

- Range Output Control (Range0To11[n].OutputControl)

- Range Configuration Flags

- Output Array

- Output on Mask (OutputOnMask.0 through OutputOnMask.15)

- Output Off Mask (OutputOffMask.0 through OutputOffMask.15)

- Range Enable (RangeEn.0 through RangeEn.15)

- RBF - Reset Blown Fuse (ResetBlownFuse)

- Control Bits

- Range High Limit or Direct Write Value (Range12To15[n].HiLimOrDirWr)

- Range Low Limit (Range12To15[n].LowLimit)

- Range Output Control (Range12To15[n].OutputControl)

- Range Configuration Flags (12To15)

- Input Array

- Input State (InputStateA0 through InputStateZ1)

- Readback (Readback.0 through Readback.15)

- Status Flags

- Range Active (RangeActive.0 through RangeActive.15)

- Current Count (Ctr[n].CurrentCount)

- Stored Count (Ctr[n].StoredCount)

- Current Rate (Ctr[0].CurrentRate to Ctr[3].CurrentRate)

- Pulse Interval (Ctr[0].PulseInterval and Ctr[1].PulseInterval)

- Status Flags

- 5 - Diagnostics and Troubleshooting

- A - Specifications

- B - Program a 1769-HSC Module, CompactLogix Controller, and 845F Incremental Encoder with RSLogix 5000 Software

- C - Program a 1769-HSC Module, MicroLogix 1500 Controller, and 845F Incremental Encoder with RSLogix 500 Software

- D - Programming Quick Reference

- E - History of Changes

- Glossary

- Index

- Back Cover

50 Rockwell Automation Publication 1769-UM006E-EN-P - July 2013

Chapter 3 Installation and Wiring

Mount the Module

Use these procedures to mount your module.

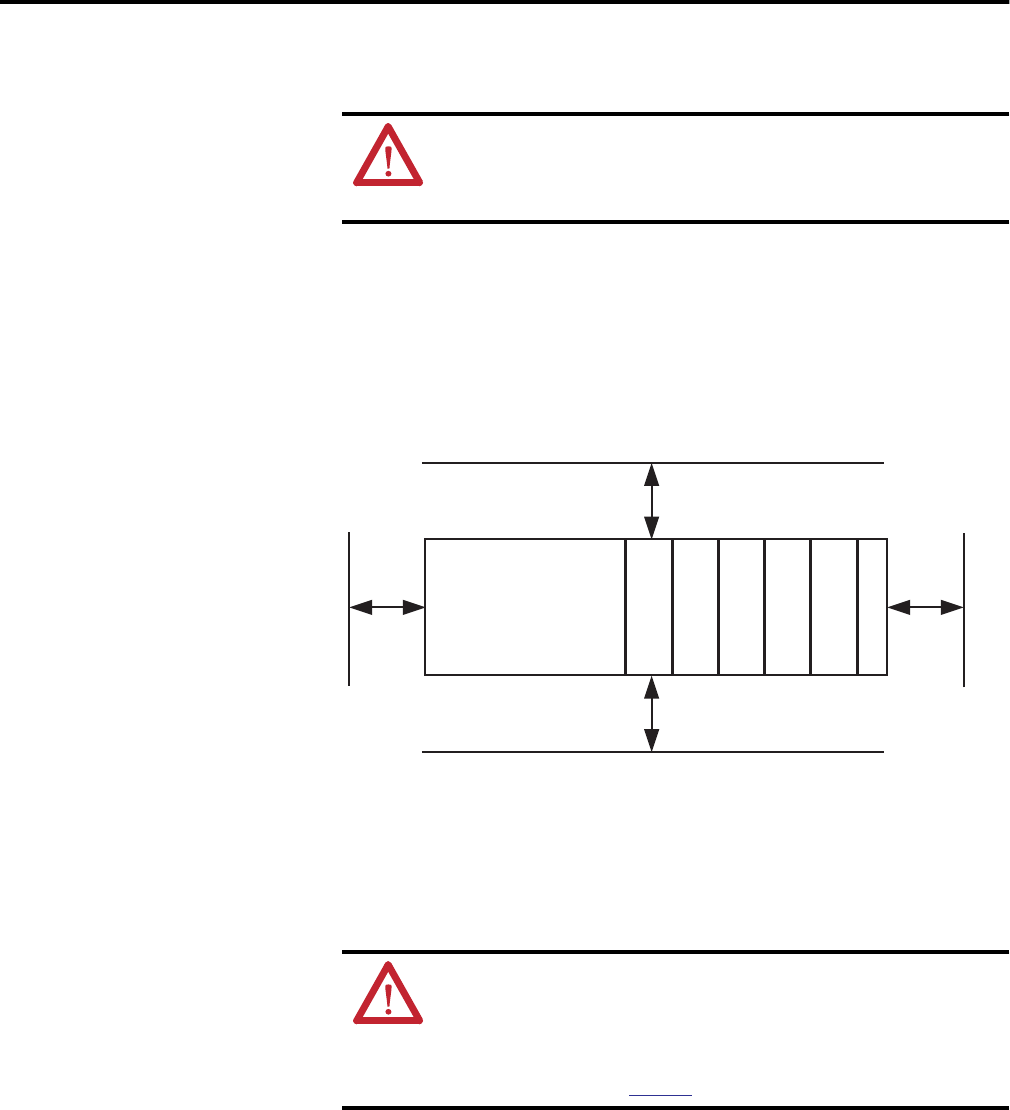

Minimum Spacing

Maintain spacing from enclosure walls, wireways, adjacent equipment, and so

forth. Allow 50 mm (2 in.) of space on all sides for adequate ventilation,

as shown.

Panel Mounting

Mount the module to a panel by using two screws per module. Use M4 or #8

panhead screws. Mounting screws are required on every module.

ATTENTION: During panel or DIN-rail mounting of all devices, be sure

that all debris (metal chips, wire strands) is kept from falling into the

module. Debris that falls into the module could cause damage at

powerup.

ATTENTION: This product is intended to be mounted to a well-grounded

mounting surface such as a metal panel. Additional grounding

connections from the power supply's mounting tabs or DIN rail (if used)

are not required unless the mounting surface cannot be grounded. Refer

to Industrial Automation Wiring and Grounding Guidelines, Rockwell

Automation publication 1770-4.1, for additional information.

Host Controller

Compact I/O

Compact I/O

Compact I/O

Compact I/O

Compact I/O

End Cap

Side Side

Top

Bottom