User Manual Owner's manual

Table Of Contents

- ArmorStart Distributed Motor Controller with EtherNet/IP User Manual

- European Communities (EC) Directive Compliance

- Table of Contents

- Chapter 1

- Product Overview

- Introduction

- Description

- Catalog Number Explanation

- Operation

- Mode of Operation

- Description of Features

- Embedded Switch Technology

- Switched vs. Unswitched Control Power Input/Output (I/O) Connections

- EtherNet/IP™ Ports

- Embedded Web Server

- EtherNet/IP LED Status Indication

- Control Module LED Status and Reset

- Electronic Data Sheet (EDS)

- Fault Diagnostics

- Standard Features

- Factory-Installed Options

- Optional HOA Keypad Configuration (Bulletin 280E/281E only)

- Optional HOA Selector Keypad with Jog Function (Bulletin 284E only)

- Source Brake Contactor and Connector (Bulletin 284E only)

- EMI Filter (Bulletin 284E only)

- Dynamic Brake Connector (Bulletin 284E only)

- IP67 Dynamic Brake Resistor (Bulletin 284E only)

- Output Contactor (Bulletin 284E only)

- Shielded Motor Cable (Bulletin 284E only)

- ArmorStart® EtherNet/ IP Features

- Notes:

- Product Overview

- Chapter 2

- Installation and Wiring

- Receiving

- Unpacking

- Inspecting

- Storing

- General Precautions

- Precautions for Bulletin 280E/281E Applications

- Precautions for Bulletin 284E Applications

- Dimensions

- Mount Orientation

- Operation

- Wiring

- Terminal Designations

- Control Power Wiring

- ArmorStart with EtherNet/IP Internal Wiring

- AC Supply Considerations for Bulletin 284E Units

- Electromagnetic Compatibility (EMC)

- Grounding

- ArmorConnect Power Media

- ArmorConnect Connections

- ArmorConnect Cable Ratings

- Ethernet and I/O Connections

- Power Connections

- Optional Locking Clip

- Installation and Wiring

- Chapter 3

- Chapter 4

- Chapter 5

- Chapter 6

- Chapter 7

- Bulletin 280E/281E/284E Programmable Parameters

- Basic Setup Parameters

- Parameter Groups

- ArmorStart EtherNet/IP Parameters

- Bulletin 280E/281E

- Bulletin 284E

- Basic Status Group

- Produced Assembly Config Group

- Starter Protection Group

- User I/O Configuration Group

- Miscellaneous Configuration Group

- Drive I/O Configuration Group (Bulletin 284E only)

- Drive Display Group (Bulletin 284E only)

- Drive Setup Group (Bulletin 284E only)

- Drive Advanced Setup Group (Bulletin 284E only)

- Clear a Type 1 Fault and Restart the Drive

- Clear an Overvoltage, Undervoltage, or Heatsink OvrTmp Fault without Restarting the Drive

- How StepLogic Works

- StepLogic Settings

- Linear List of Parameters for Bulletin 280E/281E and Bulletin 284E

- Bulletin 280E/281E/284E Programmable Parameters

- Chapter 8

- Chapter 9

- Chapter 10

- Chapter 11

- Chapter 12

- Appendix A

- Applying More Than One ArmorStart Motor Controller in a Single Branch Circuit on Industrial Machinery

- Introduction

- ArmorStart LT Product Family

- Multiple-Motor Branch Circuits and Motor Controllers Listed for Group Installation – General

- Maximum Fuse Ampere Rating According to 7.2.10.4(1) and 7.2.10.4(2)

- Explanatory Example

- Input and Output Conductors of Bulletin 290E and 291E Controllers (a)

- Input and Output Conductors of Bulletin 294E Controllers (b)

- Combined Load Conductors (c)

- Applying More Than One ArmorStart Motor Controller in a Single Branch Circuit on Industrial Machinery

- Appendix B

- CIP Information

- High Level Product Description

- CIP Explicit Connection Behavior

- CIP Object Requirements

- Identity Object

- Assembly Object

- Connection Manager Object

- Discrete Input Point Object

- Discrete Output Point Object

- Parameter Object

- Parameter Group Object

- Discrete Input Group Object

- Discrete Output Group Object

- Control Supervisor Object

- Overload Object

- Device Level Ring (DLR) Object

- Qos Object

- DPI Fault Object

- DPI Alarm Object

- Interface Object

- TCP/IP Interface Object

- Ethernet Link Object

- CIP Information

- Appendix C

- Using DeviceLogix

- DeviceLogix Programming

- DeviceLogix Programming Example

- Import and Export

- Bulletin 284 - VFD Preset Speed Example

- DeviceLogix Ladder Editor Example

- ArmorStart 280 and 281 Status Bits

- Bulletin 280 and 281 ArmorStart Fault Bits

- Bulletin 280 and 281 ArmorStart Outputs

- Bulletin 280 and 281 ArmorStart Produced Network Bits

- Bulletin 284 ArmorStart Status Bits

- Bulletin 284 ArmorStart Fault Bits

- Bulletin 284 ArmorStart Outputs

- Bulletin 284 ArmorStart Produced Network Bits

- Using DeviceLogix

- Appendix D

- Appendix E

- Appendix F

- Back Cover

214 Rockwell Automation Publication 280E-UM001B-EN-P - July 2012

Chapter 9 Diagnostics

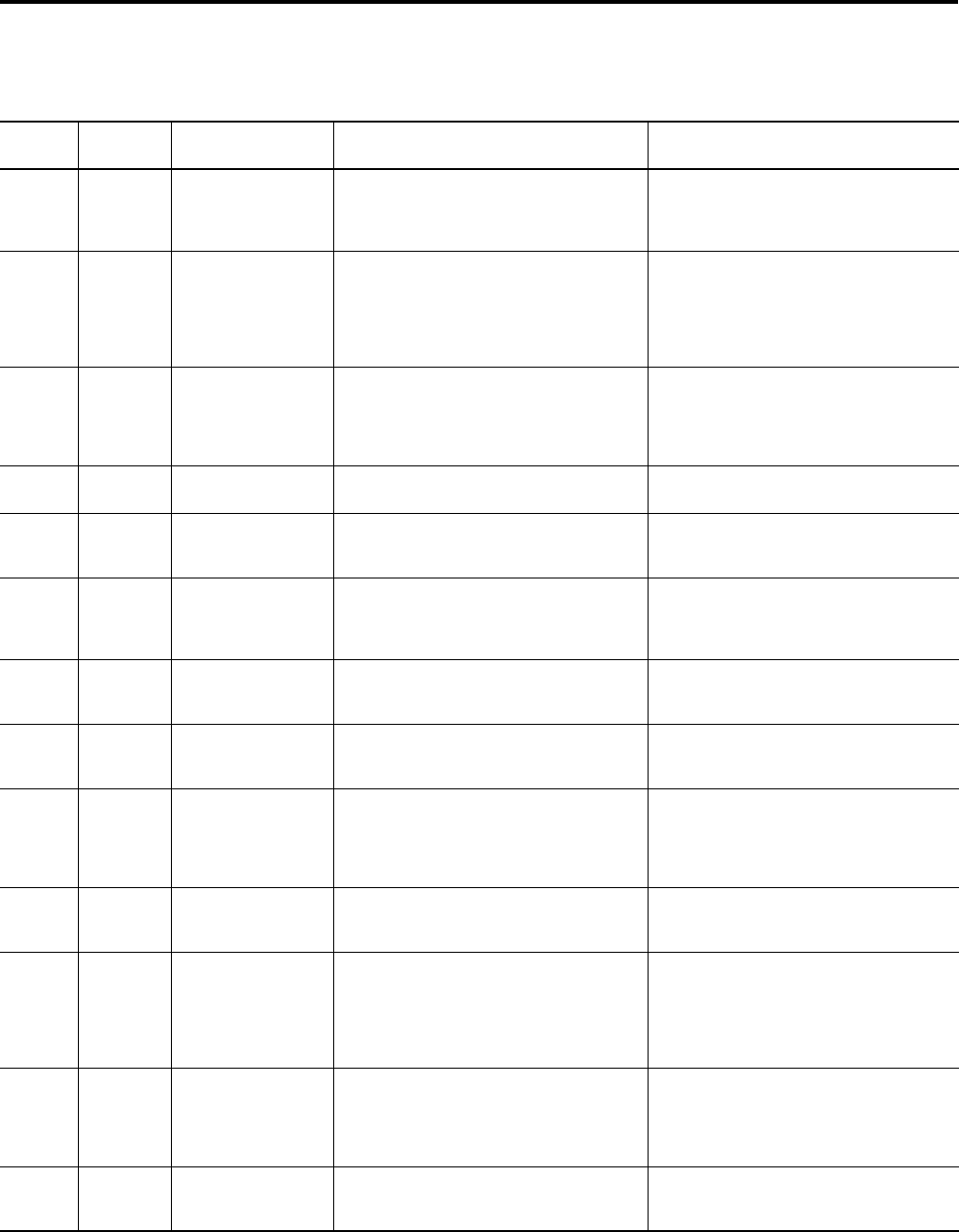

Table 37 - Fault LED Indicators for 284E

Bit/Blink

Pattern

Auto-

Resettable 284E Trip Status Description Action

1 No Short Circuit The circuit breaker (140M) has tripped. Determine cause of trip. Try to reset the circuit breaker

using the disconnect handle. If the conditions continue,

check power wiring or replace based module. This cannot

be disabled.

2Drive

Controlled

Overload

(Drive Codes 7 and 64)

An excessive motor load exists 1. Reduce load so drive output current does not exceed

the current set by Parameter 133 (Motor OL Current).

2. Verify Parameter 184 (Boost Select) setting.

3. Drive rating of 150% for 1 minute.

4. Reduce load or extend Accel Time two hundred

percent or when 3 seconds has been exceeded.

3Drive

Controlled

Phase Short

(Drive Codes 38…43)

1. Phase U, V, or W to Gnd. A phase to ground fault has

been detected between the drive and motor in this

phase.

2. Phase UV, UW, or VW Short. Excessive current has been

detected between these two output terminals.

Check the wiring between the drive and motor. Check

motor for grounded phase. Check the motor and drive

output terminal wiring for a shorted condition. Replace

drive if fault cannot be cleared.

4Drive

Controlled

Ground Fault

(Drive Code 13)

A current path to earth ground has been detected at one

or more of the drive output terminals.

Check the motor and external wiring to the drive output

terminals for a grounded condition.

5Drive

Controlled

Stall

(Drive Code 6)

Drive is unable to accelerate motor. Increase Parameters 139…167 (Accel Time x) or reduce

load so drive output current does not exceed the current

set by Parameter 189 (Current Limit 1).

6

Parameter 23

(PrFlt Reset

Mode)

Control Pwr Loss (Switched

Power)

The ArmorStart has detected a loss of the control power

voltage.

Check control voltage, wiring, and proper polarity (A1/A2

terminal). Also, check and replace the control voltage

fuse, if necessary. This fault can be disabled and is

disabled by default.

7

Parameter 23

(PrFlt Reset

Mode)

Input Fault This error indicates a shorted sensor, shorted input

device, wiring input mistakes, or a blown output fuse.

If this fault occurs, the offending problem should be

isolated or removed prior to restarting the system. This

fault can be disabled and is disabled by default.

8

Parameter 23

(PrFlt Reset

Mode)

Over Temperature This fault is generated when the operating temperature

has been exceeded. This fault cannot be disabled.

Check for blocked or dirty heat sink fins. Verify that

ambient temperature has not exceeded 40 °C (104 °F).

1. Clear the fault or cycle power to the drive.

9Drive

Controlled

Over Current

(Drive Codes 12 and 63)

The drive output current has exceeded the hardware

current limit.

Check programming. Check for excess load, improper

Parameter 184 (Boost Select) setting. DC brake volts set

too high or other causes of excess current. Parameter 198

(SW Current Trip) has been exceeded, check load

requirements and Parameter 198 setting.

10

Parameter 23

(PrFlt Reset

Mode)

Control Power (24V DC) Lost

(Unswitched Power)

The 24V DC power supply is below tolerance threshold. Check the state of the network power supply (A3/A1

terminal) and look for media problems. This fault can be

disabled and is disabled by default.

11 No Internal Comm

(Refer to Parameter 61 for

details on this fault. F81 is a

VFD fault. This could also

happen if control power is

lost.)

Communication with either the control module (VFD) or

Control module has stopped.

Refer to section Fault 11 Detail. If the problem persists

replace the unit.

12 Drive

Controlled

DC Bus Fault

(Drive Codes Reference 3, 4

and 5)

Power Loss - DC bus voltage remained below 85% of

nominal. UnderVoltage - DC but voltage fell below the

minimum value. OverVoltage - DC bus voltage exceeded

maximum value.

Monitor the incoming AC line for low voltage or line

power interruption. Check the input fuses. Monitor the

AC line for high line voltage or transient conditions. Bus

overvoltage can also be caused by motor regeneration.

Extend the decel time or install dynamic brake option.

13 No EEprom

(PF Drive Code Reference

100)

The checksum read from the board does not match the

checksum calculated.

Set Parameter 141 (Reset to Defaults) to Option 1 “Reset

Defaults”.