Manual

Manual/MDI Operation Modes

Chapter 1

1-2

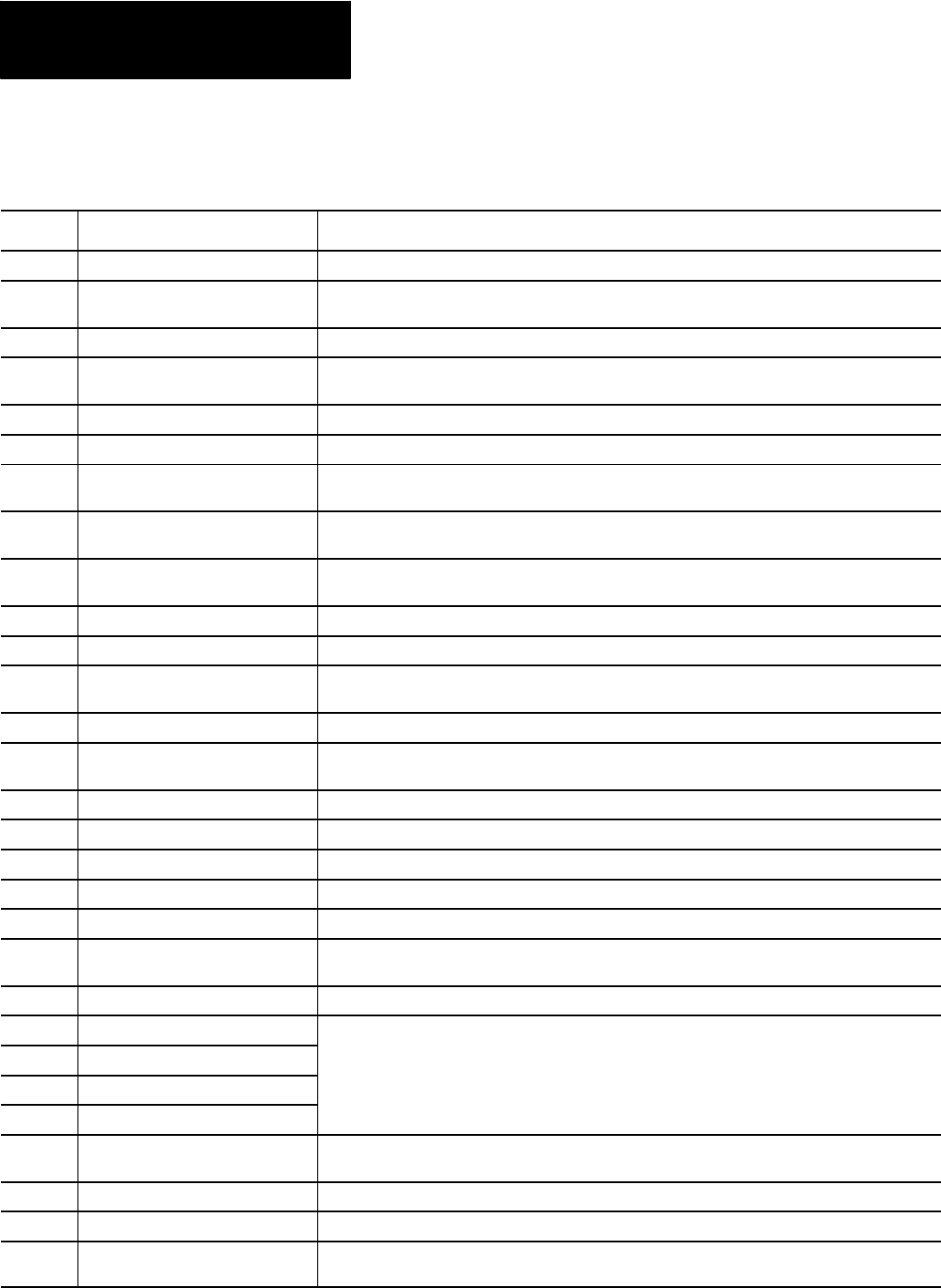

Table 1.A

Manual Organization

Chapter Title Summary

1 Manual Overview Manual overview, intended audience, definitionof key terms, howto proceed.

2 Basic ControlOperation A brief descriptionof the control’ s basicoperation includingpower up, MTB panel, operator panel,

access control, andE-STOP.

3 Offset Tables and Setup Basic setupof the offset table, other initial operating parameters.

4 Manual andMDI Operation How touse themanual operatemode including, homingthe machine, joghand-wheel, jog

continuous, and jog increment. Alsocovered arethe basicsfor MDI operation.

5 Editing Programs On Line How tocreate, edit,and savea part programon line.

6 Editing Part Program Off Line How tocreate, edit, and savea part programsfrom ODS off line.

7 Running a Program How toselect and executea programautomatically. This covers programchecking aswell aspart

production. Alsodetails on special running conditions.

8 Displays/ Graphics How toaccess andinterpret the different position displays. How touse theQuick Checkand Active

Program graphicsfeatures.

9 Communications Communications withperipheral devices. Includes sectionson communicationport parameters,

inputting and outputting AMP, PAL, Offsets, and programs.

10 Introduction to Programming Tape format, structure and format of the programminglanguage for thecontrol.

11 Coordinate System Offsets Machine coordinate system, Preset Work coordinate systems, PALoffsets, andexternal offsets

12 Overtravels andProgrammable

Zones (G22, G23)

Hardware and software overtravels, programmable zone2 (G22, G23), programmablezone 3

(G22.1, G23.1), and resetting overtravels

13 Coordinate Control Describesabsolute/incremental modes, inch/metricmodes, radius/diameter modes, and scaling

14 Axis Motion G-words definehow thetool ispositioned tothe endpoint of amove. Also sectionson automatic

machine home, dwell, mirroring, and axis clamp

15 QuickPath Plus Describes QuickPathPlus programming

16 Chamfering and Corner Radius Describes the,C- and ,R-words programmed for chamfering andcorner radius

17 Spindles Describes spindle speed control, spindle orientation, spindle direction, and Virtual Caxis

18 Programming Feedrates Describes acc/dec, AMP-assignedfeedrates, feedrate control, short blockacc/dec

19 Dual AxisOperation Describes parking, homing, programming, offset management for adual axis

20 Tool Control Selecting a tool. Activating anddeactivating toollength offsets. Also toolcontrol featuressuch as

Random Tooland ToolLife Management.

21 Tool Tip RadiusCompensation Describes theTool Tip RadiusCompensation feature(TTRC) that offsets for different tool diameters.

22 Single--Pass Turning Cycles Description and use of fixed (canned) cyclesfor turning operations, andthe G--codes andparameters

u

s

e

d

t

o

d

e

f

i

n

e

t

h

e

m

.

23 Grooving/Cutoff Cycles

u

s

e

d

t

o

d

e

f

i

n

e

t

h

e

m

.

24 Compound Turnign Routines

25 Thread Cutting

26 Drilling Cycles Description and use of the fixed(canned) cycles for drillingoperations andthe G--codes and

parameters usedto definethem.

27 Skip and Gauging Cycles Describes the9/Series Probingfeatures. Includes thetool measuringgauge feature.

28 Paramacros Describes paramacros includingcalling, arithmetic functions, looping, decisionmaking

29 Program Interrupts Describes theprogram interrupt feature. This feature is used tocall asubprogram or paramacro

program whenever asignal correspondingto that program issent to PAL bythe operator.