Manual

Introduction to Programming

Chapter 10

1

0

-

2

6

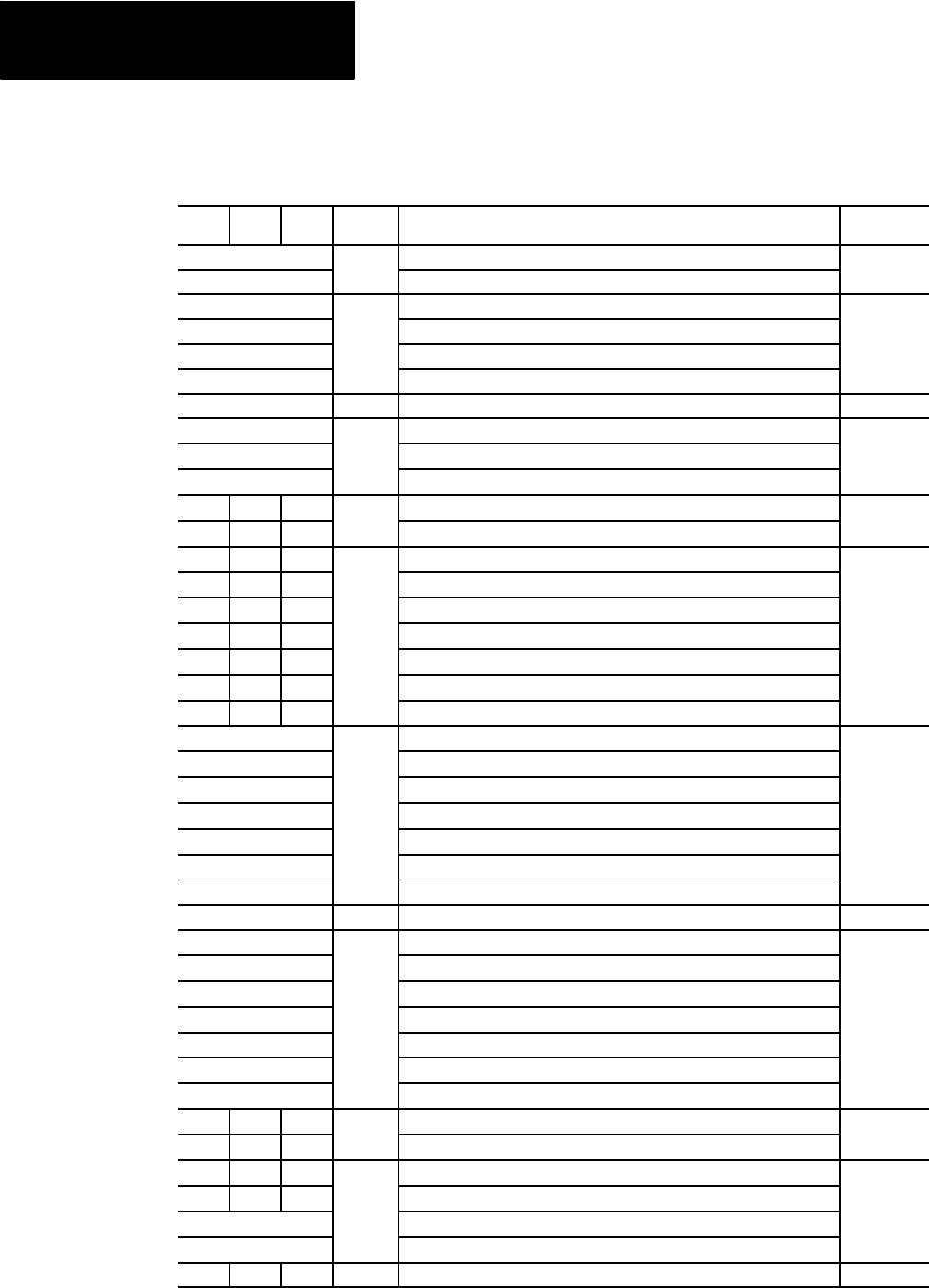

Table 10.E (continued)

G-code Table

A B C Modal Function Type

G59.2 Preset WorkCoordinate System 8

G59.3 Preset WorkCoordinate System 9

G61 13 Exact Stop Mode Modal

G62 AutomaticCorner Override

G63 Tapping Mode

G64 CuttingMode

G65 00 Paramacro Call Non-Modal

G66 14 Paramacro call Modal

G66.1 Paramacro call

G67 Paramacrocall cancel

G20 G20 G70 06 Inch system selection Modal

G21 G21 G71 Metricsystem selection

G70 G70 G72 00 O.D. and I.D. FinishingCycle Non-modal

G71 G71 G73 O.D. andI.D. Roughing Cycle

G72 G72 G74 Roughfacing cycle

G73 G73 G75 Casting/forgingroughing cycle

G74 G74 G76 FaceGrooving Cycle

G75 G75 G77 O.D. andI.D. Grooving Cycle

G76 G76 G78 O.D. andI.D. Multi-Pass ThreadingRoutine

G80 09 Cancel or endfixed cycle Modal

G81 Drillingcycle (no dwell, rapid out)

G82 Drillingcycle (dwell, rapid out)

G83 Deephole peck drilling cycle

G83.1 Deep hole peck drillingcycle (dwell)

G84 Right handtapping cycle

G84.1 Left hand tapping cycle

G84.2 Right hand solid tapping cycle

G84.3 Left hand solid tapping cycle

G85 Boringcycle (no dwell, feed out)

G86 Boringcycle (spindle stop, rapid out)

G86.1 Boring cycle (spindle shift)

G87 Backboring cycle

G88 Boringcycle (spindle stop, manual out)

G89 Boringcycle (dwell, feed out)

---- G90 G90 03 Absolute mode Modal

---- G91 G91 Incrementalmode

G50 G92 G92 00 Coordinate offset using toolpositions Non-modal

G50 G92 G92 Maximum CSSSpindle RPM

G92.1 Coordinate system offset cancel

G92.2 Cancel select offsets

G98 G94 G94 05 Feed per minutemode Modal