Manual

Tool Tip Radius Compensation (TTRC)

Function

Chapter 21

21-4

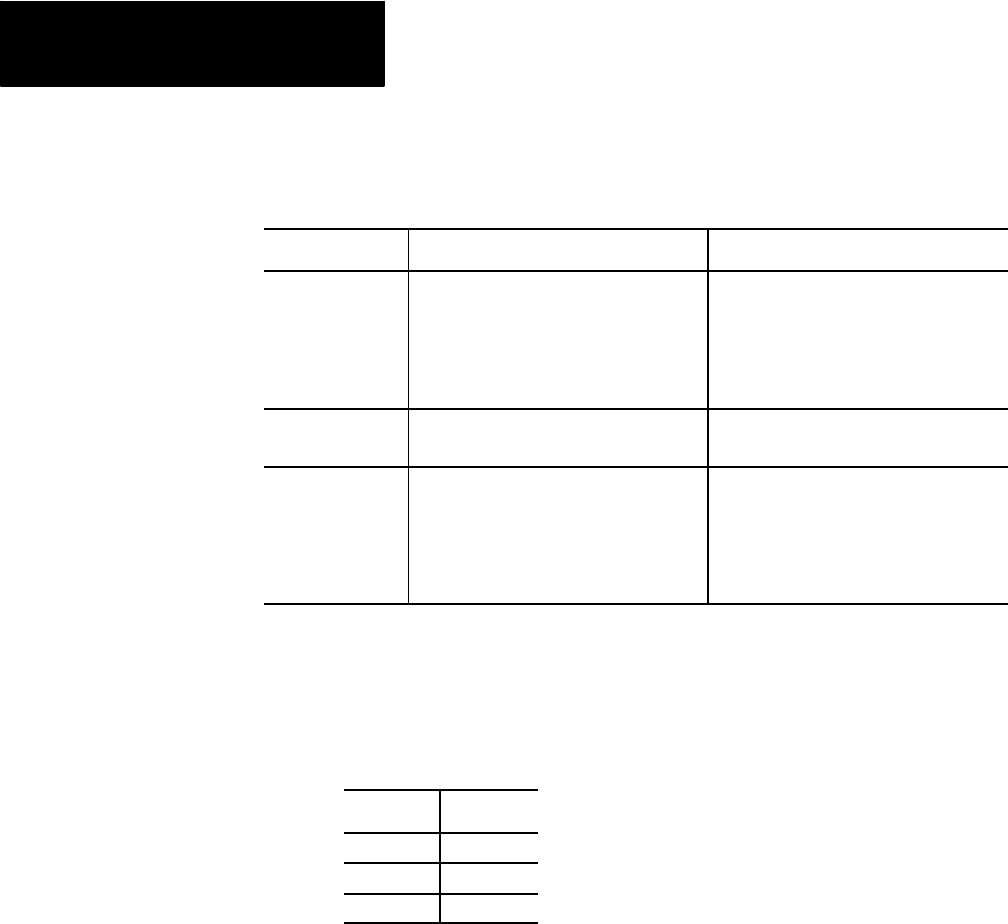

This table highlights the differences between the two types:

Type of Move Type A Type B

Entry Move Into

TTRC

-- The tooltakes theshortest possible

path to its offset position.

-- The tool stays at least oneradius away

from thestart-point of the next blockat

all times.

-- Extra motion blocks canbe generated

to attempt to prevent gouging of the

part as mayoccur in Type A.

Tool

Path

-- Same asType B. -- Same asType A.

Exit Move From

TTRC

-- The tooltakes theshortest path tothe

end-point of the exit move for both

inside and outside corners.

-- The tooltakes theshortest path tothe

end-point of exit move for inside

corners only.

-- For outside corners, thetool stays at

least one radius away from the

end-point.

Your system installer determines whether to use type A or type B by a

control in AMP.

These G-codes are used for TTRC:

G-code: TTRC, :

G41 left

G42 right

G40 cancel

Left or right is defined as offsetting the tool to the left or right of the

programmed cutting path when facing the direction of cutter motion.

Important: If you set a negative value in the offset tables as the tool

radius, this reverses compensation direction (tool left or right) for the G41

and G42 codes. G41 and G42 are also reversed during the mirroring

operation. See chapter 14.

All of these G-codes are modal and belong to the same modal group.

21.1

Programming TTRC