Manual

Grooving/Cutoff Cycles

Chapter 23

23-4

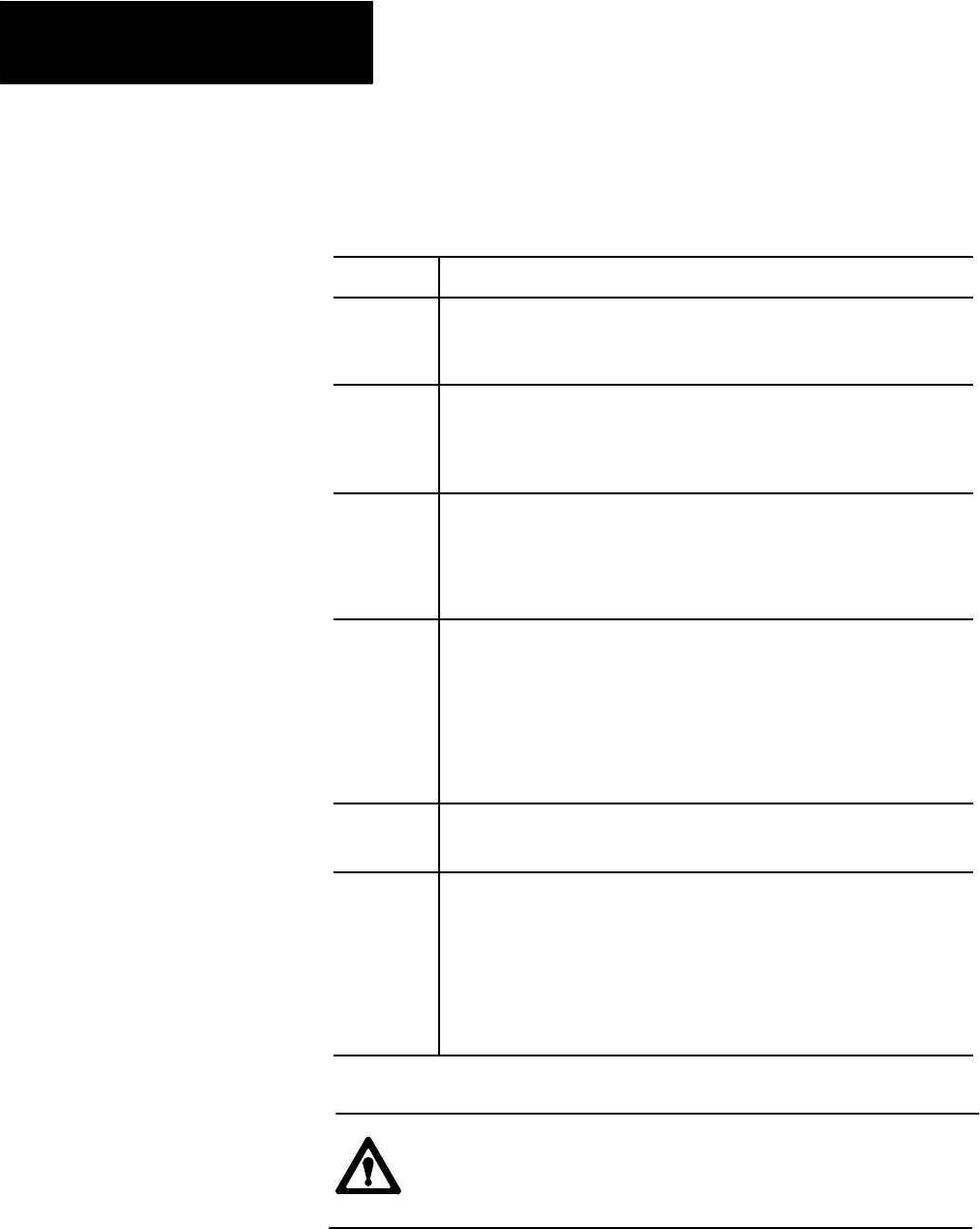

The format for this cycle is:

G76X__Z__I__K__F__D__;

Where : Is :

X__ the locationwhere thelast groove iscut. If only onegroove isto becut do not

program X. This maybe programmedas either anincremental or absolutevalue.

Remember that itsvalue isalso affected bydiameter or radius modes(G07 and

G08).

Z__ the totaldepth of thegroove from theZ coordinate position of the tool priorto the

execution of the G76 block. If this cycle is to be used as a cut off cycle the depth

programmed here should drive thetool through theface of the part. This value

represents thelocation of thebottom of thegroove cut. This maybe

programmed as either an incremental or absolute value.

I__ the distancebetween eachgroove. If the distancebetween thelocation of the

last groove (programmed with X) and thenext to thelast groove isless thanthe

value programmed with I, then theI value isnot used todetermine theposition of

the last groove. The last grooveis always cut at thelocation programmed with

X. The I parameter isalways programmedas an incremental, radius value

regardless of thecurrent mode of thecontrol.

K__ the amount that thecutting toolinfeeds intothe workpiecewith eachstep. The

step is followed bya retract of amount e (set in AMP bythe systeminstaller).

The cutting tool theninfeeds intothe workpiecean amount K+ e, retractsan

amount e, infeeds K +e, retracts e, etc. This repeatsuntil thetotal

programmed depth of the groove Z is reached. When thisdepth isreached the

cutting tool stops infeedingand either shiftsan amount D (if programmed) or

retracts tothe startingcoordinate at rapidfeedrate. The K-wordis always

programmed as an incrementalvalue regardlessof the current mode of the

control.

F__ the desiredfeedrate for thegrooving infeedmoves. The valueentered withthis

parameter replacesthe currentlyactive feedrate. It is optionalin thegrooving

block. If F isnot programmed thecurrently activefeedrate isused.

D__ the sizeof the incrementalshift move madeby thetool whenthe fulldepth of a

cut off hasbeen reached. This parameter must beprogrammed evenif its value

is zerowhen not usingthis cycleas acutoff. A valueother than zerois assigned

to D only if thegrooving cycleis beingused asa cut off cycle. It is alwaysan

incremental valueregardless of thecurrent mode. The signof the value

programmed with the D parameter determines theshift direction andshould

move the tool awayfrom the part. Programming thisshift move helpsto provide

a good finish since thecutting tool isnot touching the part when it is retracted at

the rapid feedrate.

CAUTION: The shift programmed with a D parameter is

executed as a rapid move. Make sure that the cutting tool is

clear to shift at the end of the grooving cycle.