Manual

Compounding Turning Routines

Chapter 24

24-4

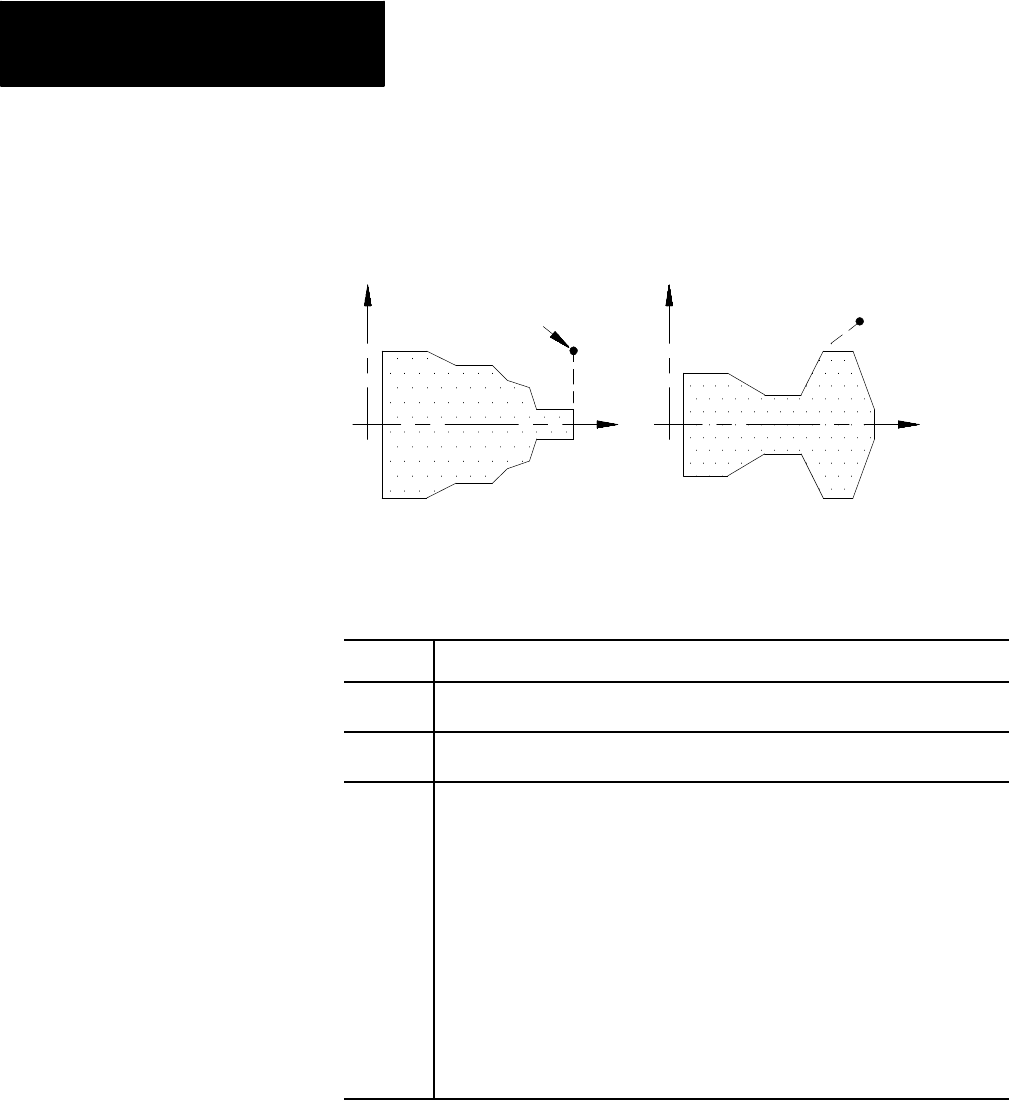

Figure 24.2

Workpiece Finish Contour Case 1 and Case 2 (G73)

X

Start Point

Z

X

Start Point

Z

Case 1

Case 2

The G73 block is programmed with this format:

G73P__Q__U__W__I__K__D__R__F__S__T__;

Where : Is :

P__ thesequence number (N-word) of thefirst block inthe set of contour blocksthat

define the final contour.

Q__ thesequence number (N-word) of thelast block inthe set of contour blocksthat

define the final contour.

U W determinethe finishingallowance that isleft on thepart when theroutine is

completed. This finish allowanceis typicallyremoved laterin the program whena

G72 finishing routine block is executed. The actualvalue of the finish allowance is

equal tothe averageof the Uand Wparameters (U+W)/2. It is not necessaryto

enter bothof these parametersin thecalling block. If only oneis entered, thecontrol

uses half of theentered parametervalue asthe finish amount. The finishallowance

is optionaland doesnot need tobe programmed. See Figure24.3 todetermine the

sign of U and W. U and Ware alwaysprogrammed asincremental values.

Important: This manualmakes theassumption that Uand Ware assignedin

AMP asthe incrementalaxis namesthat correspond tothe Xand Zaxes

respectively.

Important: The value assigned to U isaffectedby radius/diameter mode

(G08/G09). W is not affected byradius diameter mode. If programming in diameter

mode the value of the finishallowance isreally ((U/2)+W)/2.