Manual

Thread Cutting

Chapter 25

2

5

-

7

Where : Is :

X This parameter isthe endpoint of the threadcutting move in the X axis. This parameter maybe an incremental orabsolute andradius or

diameter value. If not present there must bea Zparameter. If an Xparameter is present, it indicateseither aface, tapered, or lead-in

thread. When usedin aG33 blockwithout a Zparameter, a facingthread ismade parallelto theX-axis at theZ axisposition prior to the

G33 block. X values maybeentered asa radiusor a diameter value. X may alsobe programmedas anincremental or absolutevalue.

The initial minor diameter of anystraight or tapered threadis determinedby theposition of theX axis priorto theG33 block.

Z This parameter isthe endpoint of the threadcutting move in the Zaxis. This parameter maybe anincremental or absolutevalue. If not

present there must be an X parameter. When aZ parameter is used in aG33 blockwithout an X parameterthe threadingpass ismade

parallel tothe Z-axisat whatever X positionthe tooltip wasat prior to the G33block.

E F This parametermay beentered byusing either an E- or F-word. It represents thethread leadalong theaxis withthe largest programmed

distance to travel tomake thethread cut. It is mandatory whencutting anythreads.

If the E-word is programmed, itsvalue (signignored) isequal to the number of threadsper inch or inchesper thread(determined inAMP)

regardless of whetherinch ormetric modeis activeat the time.

If the F-word is programmed, itsvalue (signignored) isthe threadlead ininches per revolutionor millimeters per revolution, dependingon

the mode in which thecontrol is operating.

Q This optionalparameter provides arelative valuefor the start offset angle of the thread. Its primary useis incutting multistart threads.

For example, if athreading passwere madewith avalue of zerohere, and thenfollowed byanother pass witha valueof 180 thenthe

second cut would be started 180degrees from thefirst resulting ina twostart thread. If two morepasses arethen made, onewith a

parameter valueof 90 andone witha valueof 270, the result wouldbe afour-start thread.

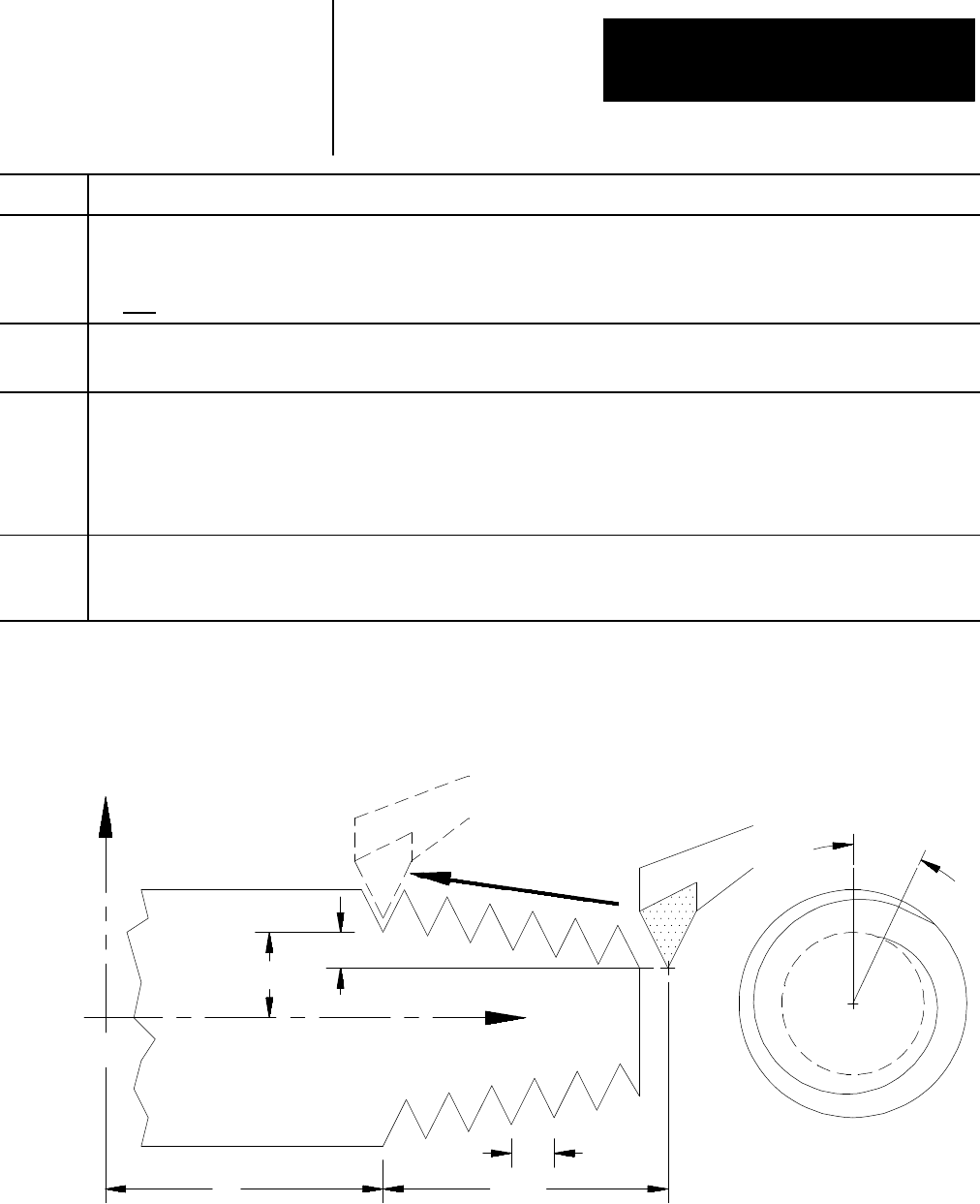

Figure 25.4

G33 Block Parameters

Z

Inc.

Z

Abs.

Z

X Abs.

X Inc.

X

Q

1/E, E or F

Important: Do not re-program the G33 command in consecutive threading

blocks. Doing so will cause the control to pause axis motion (possibly

damaging the thread) while the axis re--synchronizes with the spindle.

Consecutive threading blocks in the following example are blocks N3 and

N4, and blocks N8 and N9.