Manual

Thread Cutting

Chapter 25

2

5

-

2

1

Programming Multipass Thread Cutting

Before programming the G78 threading routine, the cutting tool must be

positioned to the point from which the routine is to be executed. This point

is the end-point of each complete cycle of the threading routine’s

execution.

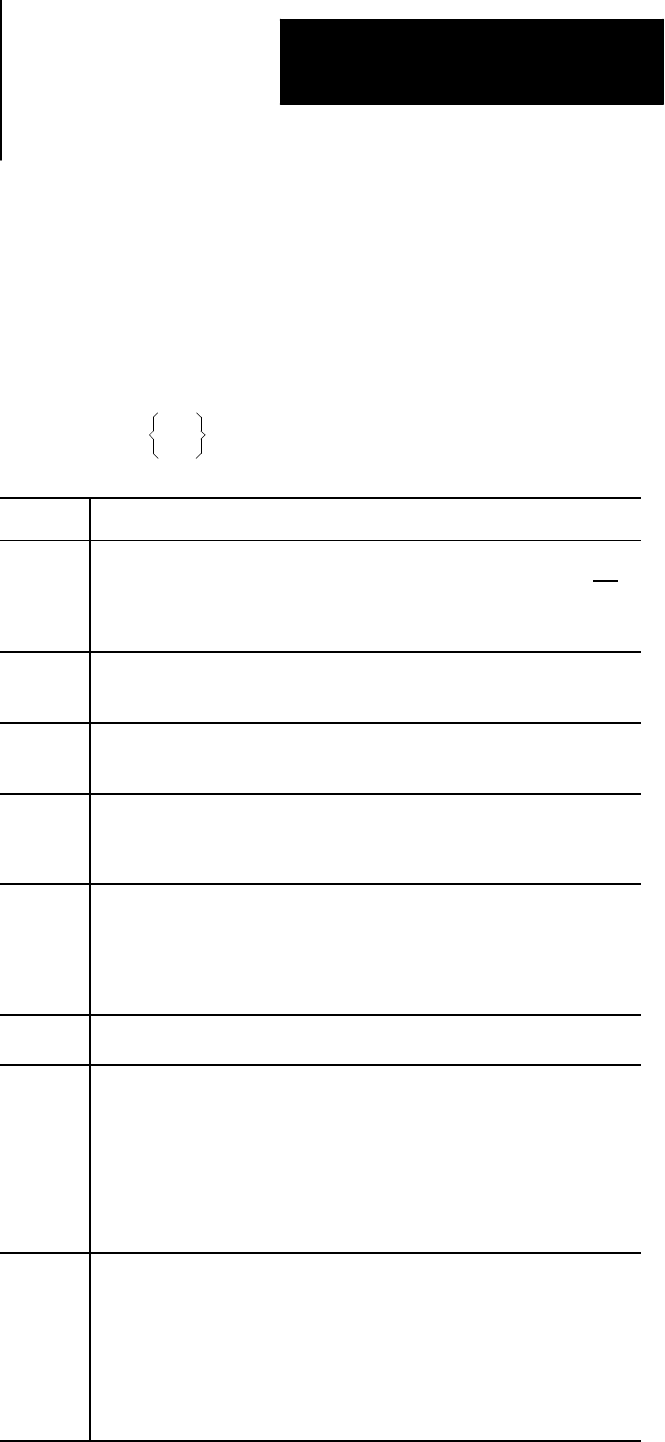

Use this format to program a multipass thread cutting routine:

G78X__Z__K__D__ F__ A__P__I__;

E

Where : Is :

X: This parameter isthe coordinatevalue of theroot (depth) of the thread. If

programming a tapered thread, it is the coordinatevalue to be attained at theend

of the last threading pass (assumethere isno chamfer cut at the endof the

pass). X values maybe enteredas aradius or adiameter value. X mayalso be

programmed as an incrementalor absolutevalue.

Z: This parameter isthe Zcoordinate valueof the endof the threadcutting pass. Z

parameters arealways enteredas aradius valueregardless of thecurrent mode.

Z may also beprogrammed asan incremental or absolute value.

K: This parameter isan unsignedvalue (alwaysprogrammed aspositive). It

programs thedistance fromthe threadroot (as determinedby theX parameter to

the top of the thread. K is alwaysprogrammed asa radiusvalue.

D: This parameter programsthe depthof cut (designated inradius) for thefirst pass.

It is anunsigned value(always programmedas positive). The depthof following

passes isdetermined bythis valueand thetype of infeedselected withthe P

parameter.

A: This parameter programsthe angleof the tooltip. It must be enteredas an

integer valuefrom 0 to120 (correspondingto 0-120degrees). Not programming

a value for A isthe sameas A0. A0 wouldbe the same as a plungetype infeed.

The value entered here determines theangle that the infeed moves makes,

which also determines thefinal threadangle. See thetool infeedsection that

follows fordetails.

P: This parameter determinesthe toolinfeed. It must be enteredas aninteger

value from one tofour. See thetool infeedsection that followsfor details.

E,F: This parameter maybe enteredby usingeither E or Ffor the threadlead

(as inG33).

If the E-word is programmed, itsvalue (alwaysunsigned) isequal to the number

of threads perinch orinches perthread (determinedin AMP)regardless of

whether inchor metric modeis activeat the time.

If the F-word is programmed, itsvalue (alwaysunsigned) isthe threadlead in

inches perrevolution ormillimeters perrevolution, depending onthe modein

which the control isoperating.

I This isthe changein radiusof the thread(on theX axis) that thethreading pass

makes asit reaches theend-point of the threadcutting pass. The end-point is

the X position programmedwith theX-word. I is anincremental, signed distance

(+ or -) added tothe Xparameter to determinethe start-point of the threading

pass onthe Xaxis. If a chamfer isbeing cut at theend of thethread cutting

pass, it does not affect the value programmed here. This parameter shouldbe

entered as if no chamferwere beingcut. I is always anincremental value

regardless of thecurrent mode. This parameteris alwaysentered asa radius

value regardless of the current mode.